GY-9150 nine-axis Motion Tracking components

Contents

Introduction

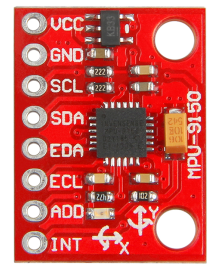

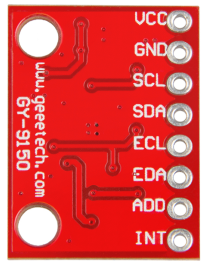

MPU-9150 is the world's first nine-axis Motion Tracking components designed for low-power, low-cost, high-performance consumer electronics products as smart phones, tablet, wearable sensors and other devices. GY-9150 Module integrates MPU6050 (three-axis gyroscope + tri-axial accelerometer) and AK8975 three-axis digital electronic compass on one chip, simplifying the hardware circuit, reducing the PCB size. In addition, it contains a DMP (Digital Motion Processor) that can process 9-axis sensor component fusion algorithms and a run-time calibration firmware. GY-9150 Module can help customers eliminate troubles of signals-regulating, combining fusion algorithms technology and factory calibration when choosing different brands of Motion Tracking components.

GY-9150 Module has the following characteristics:

1. Small in size

2. MPU-9150 internal integration (three-axis gyroscope + tri-axial accelerometer + Tri-axis compass)

3. Module Model: GY-9150, chip: MPU-9150

4. Supply voltage: 3.3v-5v

5. Communication: standard IIC communication protocol

6. in-built16 bit AD converter, 16-bit data output (field 13)

7. Tri-axis angular rate sensor (gyro) with sensitivity up to 131 LSBs/dps and a full-scale range of ±250, ±500, ±1000, and ±2000dps

8. Tri-axis accelerometer with a programmable full scale range of ±2g, ±4g, ±8g and ±16g

9. Tri-axis compass with a full scale range of ±1200µT

Software Resources

Test Software: Arduino-1.5.1r2

Interface specifications

Reserved interface description:

1. SCL, SDA: standard IIC communication interface

2. EDA: Auxiliary I2C serial data (Auxiliary I2C Master serial data)

3. ECL: Auxiliary I2C serial data (Auxiliary I2C Master serial clock)

4. ADO: I2C slave address (I2C Slave Address LSB)

5. INT: Interrupt digital output (Interrupt digital output)

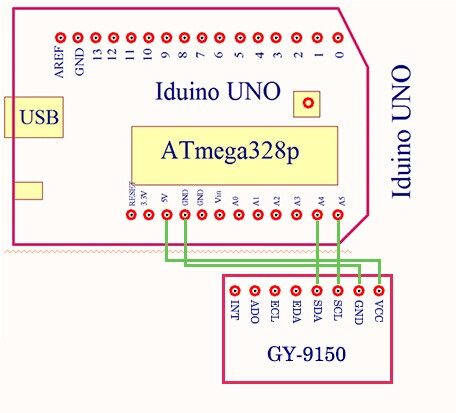

Interface Connecting and Setting

File Burning

No file burning needed for this Module.

This product is rigorously tested before shipping. If you want to re-test it and you’ll need an Iduino UNO development board, you can get an Iduino UNO development board on our online store.

More about MPU-9150

1. Rotation matrix, quaternion, Euler angles, raw data format, digital output nine-axis motion sensing data fusion algorithms

2. Axis angular rate sensor (gyroscope), sensitivity up to 131 LSBs / dps, sensing range is ± 250, ± 500, ± 1000, and ± 2000dps

3. Axis accelerometer, programmable sensing range of ± 2g, ± 4g, ± 8g and ± 16g

4. Axis electronic compass, the sensing range is ± 1200μT

5. Board level eliminates cross-axis alignment errors among the accelerometer, gyroscope and compass, reducing settling effects and sensor drift. Digital Motion Processor (DMP) reduces the complexity of the motion sensing fusion algorithms, sensor timing synchronization and gesture sensing load.

6 .support OS of Android, Linux and Windows

7. Built-in run-time bias and electronic compass correction algorithm, no need for user intervention

8. Digital input FSYNC pins support Electronic Image Stabilization and GPS programmable interrupt. Support gesture recognition, panning, zoom, scrolling, freefall interrupt, high-G interrupt, zero-motion detection, tap detection, shake detection etc.

9. VDD supply voltage range of 2.4V-3.46V; 1.8V ± 5% of VLOGIC or VDD

10. Gyro operating current: 3.6mA (full power, gyro at all rates)

11. Gyro + Accel operating current: 3.8mA (full power, gyro at all rates, Accel at 1 kHz sample rate)

12. Gyro + Accel + Compass + DMP operating current: 4.25mA (full power, gyro at all rates, Accel at 1 kHz sample rate, compass at 8Hz rate)

13. Accel low power mode operating current: 10uA at 1Hz, 20uA at 5Hz, 70uA at 20Hz, 140uA at 40Hz

14. Full Chip Idle Mode Supply Current: 8µA

15. 400 kHz Fast Mode I²C serial host interface

16. On-chip timing generator with ±1% frequency variation over full temperature range

17. 10,000g shock tolerant

18. Portable component packaging (4x4x1.06mm)

19. RoHS compliant and environmental friendly.