Rambo

Contents

Summary

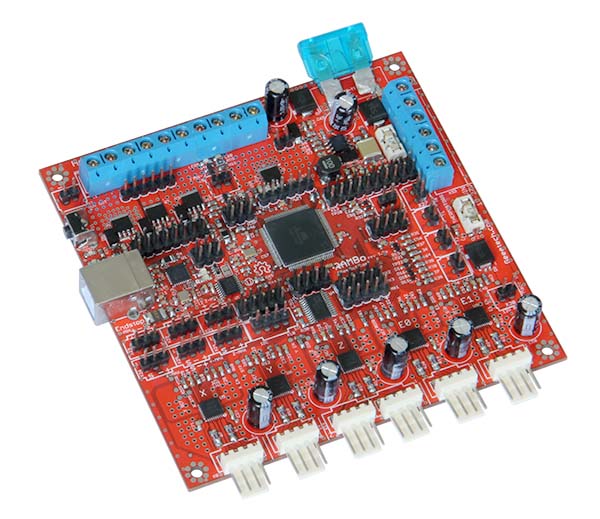

RAMBo (RepRap Arduino-compatible Mother Board) is an all in one RAMPS class motherboard targeting convenience, reliability, and performance.Our version is 1.1a.

Features

Logic

- Arduino MEGA compatible Atmega2560 and Atmega32u2 processors are compatible with all RAMPS class firmwares

- Crystals for both usb and mcu (timing accurate to 10ppm)

- 4 Thermistor jacks

- All extra pins broken out on both processors (allows using the 32u2 for LUFA AVR programmer, etc.)

- 2 channel SDRAMPS compatible SPI breakout

Motor Drivers

- 5 A4982 1/16th microstep motor drivers (A4984 1/8th prior to v1.1) (2 connectors on Z for Prusa Mendel and other dual Z printer designs)

- Digital Trimpot for stepper current control

- Current limit on driver IC VCC to prevent permanent latchup

- Microstep mode configured by MCU through firmware (no jumpers needed)

- Test points for driver control signals

- Step and Direction pins are on their own ports for synchronous movement capability

- Extra driver ports broke out for up to 3 additional drivers (some of the motor extension pins are shared with max endstop and a pin allocated for SPI-SS extensions)

PWM DC outputs (Extruders, Fans, Etc.)

- 6 outputs

- Low resistance mosfets for cool running

- Indicator led for each channel

Power

- Three independent power rails for flexible input power configurations

- Heated Bed, 15A 12-24V (version earlier than 1.1 limted to 14A 16V due to fuse rating)

- Extruders and fans, 5A 12-24V (fuse can be exchanged for up to 10A capacity) 10V-26V input voltage

- Motors and logic, 5A 12-24V (fuse can be exchanged for up to 10A capacity) 10V-26V input voltage

- Built in SMPS for 5V generation from Motor Power Input2

PCB

- 4 layer

- 2oz copper on all layers

- High quality, High temperature FR4-TG130 PCB

- Gold ENIG finishing

LCD panel support

There is now a fairly easy method for using a Smart Lcd with a Rambo board. See RamboLCD for instuctions.

Fuses and lockbits

32u2 fuses - BODLEVEL = 3V0; HWBE = [X]; DWEN = [ ]; RSTDISBL = [ ]; SPIEN = [X]; WDTON = [ ]; EESAVE = [ ]; BOOTSZ = 2048W_3800; BOOTRST = [ ]; CKDIV8 = [ ]; CKOUT = [ ]; SUT_CKSEL = EXTXOSC_8MHZ_XX_16KCK_4MS1

EXTENDED = 0xF4; HIGH = 0xD9; LOW = 0xEF

2560 Fuses BODLEVEL = 2V7; OCDEN = [ ]; JTAGEN = [ ]; SPIEN = [X]; WDTON = [ ]; EESAVE = [X]; BOOTSZ = 4096W_1F000; BOOTRST = [X]; CKDIV8 = [ ]; CKOUT = [ ]; SUT_CKSEL = EXTXOSC_8MHZ_XX_16KCK_65MS

EXTENDED = 0xFD; HIGH = 0xD0; LOW = 0xFF;

Lock bits for both only set BLB1 = LPM_SMP_DISABLE (0x0F).

Firmware

Support for RAMBo is in several firmwares.

For Marlin you will at least need to set the following variables in configuration.h:

#define MOTHERBOARD 301

The TEMP_SENSOR needs to be set to match your configuration. For a Epcos 100K thermsitor on Extruder0 and HeatedBed:

#define TEMP_SENSOR_0 1 #define TEMP_SENSOR_1 0 #define TEMP_SENSOR_2 0 #define TEMP_SENSOR_BED 1

You will likely need to tune the PID and DEFAULT_ settings to mach your hardware.

For some computers you may also need to set #define BAUDRATE 115200 to get communications.

You can adjust the motor driver settings in Configuration_adv.h: #define MICROSTEP_MODES and #define DIGIPOT_MOTOR_CURRENT

USB Driver

Windows requires a driver to communicate with RAMBo. Download this file File:RAMBo USBdriver.zip and unzip it into a known location on your computer. In windows 7, plug in your RAMBo board, and let windows fail to find the driver. Then, go to the start menu, right click on computer and click properties. On the left, click on Device Manager. Scroll down to Unknown Devices, and right click on RAMBo. Choose Update driver. CLick on "Browse my computer for driver software", then click on "Let me pick from a list of device drivers on my computer", then click the button for "Have Disk" and then click browse and point it to the file you downloaded above.

Linux and Mac use the built in CDC driver. RAMBo should show as a option in your 3D printer control interface (/dev/ttyACM0 , etc.).

Maximum motor current

In version 1.0d R30 (4.99K) limited the current to ~1.65A. this is changed in revision 1.0e (3.33K) to raise the current limit to 2A. Version 1.0d assemblies can be patched to allow setting the increased current by soldering a 10K 0603 resistor in parallel (on top of) R30.

Heated bed maximum voltage

The heated bed circuit's voltage is limited by the RGEF1400 PTC fuse which is rated to 16V. If a higher voltage is required this fuse can be replaced with a jumper wire and off board fuse holder. Make sure that your wire and solder are sufficient to carry the high current of this rail.

Motor Current

The current for the stepper motors is set by firmware controlling the 8-bit digital potentiometer. The following formula from the Allegro datasheet describes how to set the reference voltage: ITripMAX = VREF/(8 X RS). RS, the value of the sense resistor on RAMBo is equal to 0.1<math>\Omega</math>. ITripMAX is the current the stepper motors are rated for. Ideally you should start with 70%-90% of maximum. You can verify the voltage for each driver by plugging the reference voltage (VREF) measured at the X_REF test point (Y_REF,etc for the other drivers) in the following formula:

<math> V_{Ref}= I_{TripMAX} \times 0.8</math>

Note the A4982 is set to be limited to 2A. This means the adjustable voltage range is 0 to 1.66 volts. The following formula will yield the 8-bit binary value, <math>W_v</math>, to be entered into firmware or directly over SPI.

<math>W_v = \frac{V_{Ref}}{1.66} \times 255</math>

Files

RAMBo-manual:

RAMBo silk:

File:Controller final reprapdiscount.PDF

Pins

The extension headers are in the format "Extension Name" "Pin Number" "Function". Example: MX1-5 Direction = "Motor Extension 1" "Pin 5".

| Pin Number | Pin Name | Arduino Pin Name | RAMBO Function |

| 1 | PG5 ( OC0B ) | Digital pin 4 (PWM) | PWM-Ext 6 |

| 2 | PE0 ( RXD0/PCINT8 ) | Digital pin 0 (PWM) (RX0) | USB – serial comms, SER0 3 |

| 3 | PE1 ( TXD0 ) | Digital pin 1 (PWM) (TX0) | USB – serial comms, SER0 4 |

| 4 | PE2 ( XCK0/AIN0 ) | Ext2 20 | |

| 5 | PE3 ( OC3A/AIN1 ) | Digital pin 5 (PWM) | PWM-Ext 5 |

| 6 | PE4 ( OC3B/INT4 ) | Digital pin 2 (PWM) | PWM-Ext 4 |

| 7 | PE5 ( OC3C/INT5 ) | Digital pin 3 (PWM) | Bed Heater |

| 8 | PE6 ( T3/INT6 ) | Ext2 18 | |

| 9 | PE7 ( CLKO/ICP3/INT7 ) | Ext2 16 | |

| 10 | VCC | VCC | VCC |

| 11 | GND | GND | GND |

| 12 | PH0 ( RXD2 ) | Digital pin 17 (PWM) (RX2) | Serial 7 |

| 13 | PH1 ( TXD2 ) | Digital pin 16 (PWM) (TX2) | Serial 8 |

| 14 | PH2 ( XCK2 ) | Ext2 8 | |

| 15 | PH3 ( OC4A ) | Digital pin 6 (PWM) | Fan 1 |

| 16 | PH4 ( OC4B ) | Digital pin 7 (PWM) | Heat 1 |

| 17 | PH5 ( OC4C ) | Digital pin 8 (PWM) | Fan 0 |

| 18 | PH6 ( OC2B ) | Digital pin 9 (PWM) | Heat 0 |

| 19 | PB0 ( SS/PCINT0 ) | Digital pin 53 (PWM)(SPI-SS) | SPI-Ext SS 6 |

| 20 | PB1 ( SCK/PCINT1 ) | Digital pin 52 (PWM)(SCK) | SPI-Ext SCK 5 |

| 21 | PB2 ( MOSI/PCINT2 ) | Digital pin 51 (PWM)(MOSI) | SPI-Ext MOSI 4 |

| 22 | PB3 ( MISO/PCINT3 ) | Digital pin 50(MISO) | SPI-Ext MISO 3 |

| 23 | PB4 ( OC2A/PCINT4 ) | Digital pin 10 (PWM) | Z Min Endstop |

| 24 | PB5 ( OC1A/PCINT5 ) | Digital pin 11 (PWM) | Y Min Endstop |

| 25 | PB6 ( OC1B/PCINT6 ) | Digital pin 12 (PWM) | X Min Endstop |

| 26 | PB7 ( OC0A/OC1C/PCINT7 ) | Digital pin 13 (PWM) | LED, PWM-Ext 3 |

| 27 | PH7 ( T4 ) | Ext2 6 | |

| 28 | PG3 ( TOSC2 ) | Ext3 7 | |

| 29 | PG4 ( TOSC1 ) | Ext3 5 | |

| 30 | RESET | RESET | Reset |

| 31 | VCC | VCC | VCC |

| 32 | GND | GND | GND |

| 33 | XTAL2 | XTAL2 | XTAL2 |

| 34 | XTAL1 | XTAL1 | XTAL1 |

| 35 | PL0 ( ICP4 ) | Digital pin 49 | Y Direction |

| 36 | PL1 ( ICP5 ) | Digital pin 48 | X Direction |

| 37 | PL2 ( T5 ) | Digital pin 47 | Z Direction |

| 38 | PL3 ( OC5A ) | Digital pin 46 (PWM) | MX3-5 Direction |

| 39 | PL4 ( OC5B ) | Digital pin 45 (PWM) | MX2-5 Direction |

| 40 | PL5 ( OC5C ) | Digital pin 44 (PWM) | MX1-5 Direction |

| 41 | PL6 | Digital pin 43 | E0 Direction |

| 42 | PL7 | Digital pin 42 | E1 Direction |

| 43 | PD0 ( SCL/INT0 ) | Digital pin 21 (SCL) | I2C SCL |

| 44 | PD1 ( SDA/INT1 ) | Digital pin 20 (SDA) | I2C SDA |

| 45 | PD2 ( RXDI/INT2 ) | Digital pin 19 (RX1) | Serial 5 |

| 46 | PD3 ( TXD1/INT3 ) | Digital pin 18 (TX1) | Serial 6 |

| 47 | PD4 ( ICP1 ) | Ext2 14 | |

| 48 | PD5 ( XCK1 ) | Ext2 12 | |

| 49 | PD6 ( T1 ) | Ext2 10 | |

| 50 | PD7 ( T0 ) | Digital pin 38 | Digipot SS |

| 51 | PG0 ( WR ) | Digital pin 41 | X Microstep2 |

| 52 | PG1 ( RD ) | Digital pin 40 | X Microstep1 |

| 53 | PC0 ( A8 ) | Digital pin 37 | X Step |

| 54 | PC1 ( A9 ) | Digital pin 36 | Y Step |

| 55 | PC2 ( A10 ) | Digital pin 35 | Z Step |

| 56 | PC3 ( A11 ) | Digital pin 34 | E0 Step |

| 57 | PC4 ( A12 ) | Digital pin 33 | E1 Step |

| 58 | PC5 ( A13 ) | Digital pin 32 | MX1-4 Step |

| 59 | PC6 ( A14 ) | Digital pin 31 | MX2-4 Step |

| 60 | PC7 ( A15 ) | Digital pin 30 | Z Max, MX3-4 Step |

| 61 | VCC | VCC | VCC |

| 62 | GND | GND | GND |

| 63 | PJ0 ( RXD3/PCINT9 ) | Digital pin 15 (RX3) | Serial 9 |

| 64 | PJ1 ( TXD3/PCINT10 ) | Digital pin 14 (TX3) | Serial 10 |

| 65 | PJ2 ( XCK3/PCINT11 ) | Ext2 9 | |

| 66 | PJ3 ( PCINT12 ) | Ext2 11 | |

| 67 | PJ4 ( PCINT13 ) | Ext2 15 | |

| 68 | PJ5 ( PCINT14 ) | Ext2 17 | |

| 69 | PJ6 ( PCINT 15 ) | Ext2 19 | |

| 70 | PG2 ( ALE ) | Digital pin 39 | Y Microstep2 |

| 71 | PA7 ( AD7 ) | Digital pin 29 | X Enable |

| 72 | PA6 ( AD6 ) | Digital pin 28 | Y Enable |

| 73 | PA5 ( AD5 ) | Digital pin 27 | Z Enable |

| 74 | PA4 ( AD4 ) | Digital pin 26 | E0 Enable |

| 75 | PA3 ( AD3 ) | Digital pin 25 | E1 Enable |

| 76 | PA2 ( AD2 ) | Digital pin 24 | X Max, MX3-3 Enable |

| 77 | PA1 ( AD1 ) | Digital pin 23 | Y Max, MX2-3 Enable |

| 78 | PA0 ( AD0 ) | Digital pin 22 | MX1-3 Enable |

| 79 | PJ7 | Ext2 13 | |

| 80 | VCC | VCC | VCC |

| 81 | GND | GND | GND |

| 82 | PK7 ( ADC15/PCINT23 ) | Analog pin 15 | Y Microstep1 |

| 83 | PK6 ( ADC14/PCINT22 ) | Analog pin 14 | Z Microstep1 |

| 84 | PK5 ( ADC13/PCINT21 ) | Analog pin 13 | Z Microstep2 |

| 85 | PK4 ( ADC12/PCINT20 ) | Analog pin 12 | E0 Microstep2 |

| 86 | PK3 ( ADC11/PCINT19 ) | Analog pin 11 | E0 Microstep1 |

| 87 | PK2 ( ADC10/PCINT18 ) | Analog pin 10 | E1 Microstep2 |

| 88 | PK1 ( ADC9/PCINT17 ) | Analog pin 9 | E1 Microstep1 |

| 89 | PK0 ( ADC8/PCINT16 ) | Analog pin 8 | Analog-Ext 1 |

| 90 | PF7 ( ADC7/PCINT15 ) | Analog pin 7 | Thermistor 3, Analog-Ext 2 |

| 91 | PF6 ( ADC6/PCINT14 ) | Analog pin 6 | Analog-Ext 3 |

| 92 | PF5 ( ADC5/TMS ) | Analog pin 5 | Analog-Ext 4 |

| 93 | PF4 ( ADC4/TMK ) | Analog pin 4 | Analog-Ext 5 |

| 94 | PF3 ( ADC3 ) | Analog pin 3 | Analog-Ext 6 |

| 95 | PF2 ( ADC2 ) | Analog pin 2 | Thermistor 2 |

| 96 | PF1 ( ADC1 ) | Analog pin 1 | Thermistor 1 |

| 97 | PF0 ( ADC0 ) | Analog pin 0 | Thermistor 0 |

| 98 | AREF | Analog Reference | |

| 99 | GND | GND | GND |

| 100 | AVCC | VCC | VCC |

Fuses

RAMBo has 3 replaceable fuses. The small white fuse holders are Little Fuse OMNI-BLOCK fuse holders. They are compatible with NANO2 Fuses. Fast or very fast acting are recommended. An example part number for replacement fuses is 0448005.MR F2 supplies the motors and on-board power supply. F3 supplies the extruder heater and fan outputs. F4 is a 15A ATO (the type found in many automotives). F4 supplies the heated bed output.

Changelog

- 1.1b

- change stepper driver to A4982 and microstepping options are now 1,1/2,1/4,1/16

- change Fan1 output mosfet to SOT23 package and add another identical circuit to expand to 6 mosfet outputs

- change heated bed fuse from PTC to ATO (auto blade) fuse increasing heated bed rail max voltage to match others (24V max recommended PSU)

- additional decoupling caps

- change license to match Arduino's published requirements

- 1.0e

- change R30 value

- remove stop on vias and under drivers

- clarify PS_ON and other silk screen fixes

- 1.0d Initial release