Geeetech Thunder 3D printer

Contents

- 1 Introduction

- 2 Printer Maintenance

- 3 Trouble Shooting

- 3.1 Turn the printer on but the screen is black

- 3.2 The extruder keeps making a click sound

- 3.3 Nothing is printing

- 3.4 Mintemp error

- 3.5 Automatic leveling failed

- 3.6 Spring steel sheet problem

- 3.7 Filament sensor

- 3.8 Nozzle discharge abnormality

- 3.9 The extruder gear slips and makes abnormal noise

- 3.10 First layer abnormal

- 3.11 Layer shift

- 3.12 X/Y axis Closed-loop Control Abnormality

- 3.13 G-code for part cooling fan and auxiliary part cooling fan

Introduction

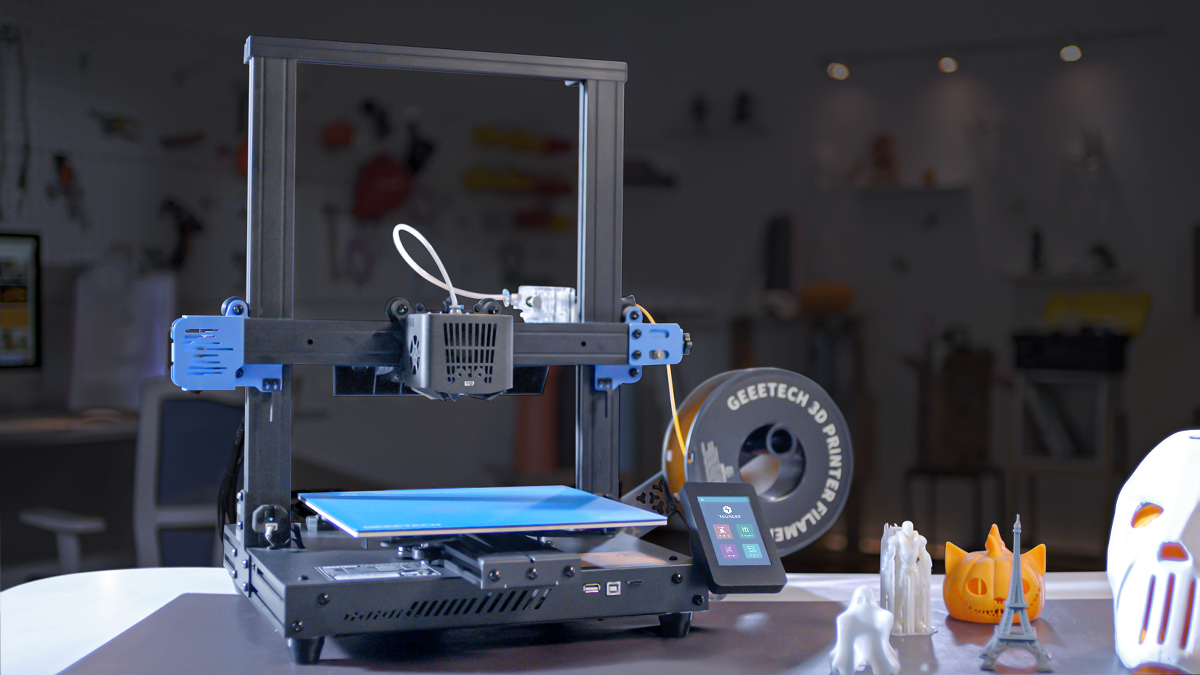

Thunder is a high speed FDM 3D printer with a printing speed of up to 300mm/s. After two years of research and development and testing by GEEETECH engineers, it has achieved high speed printing while ensuring excellent printing quality. It is an excellent 3D printer that can save a lot of precious time for 3D printing enthusiasts.

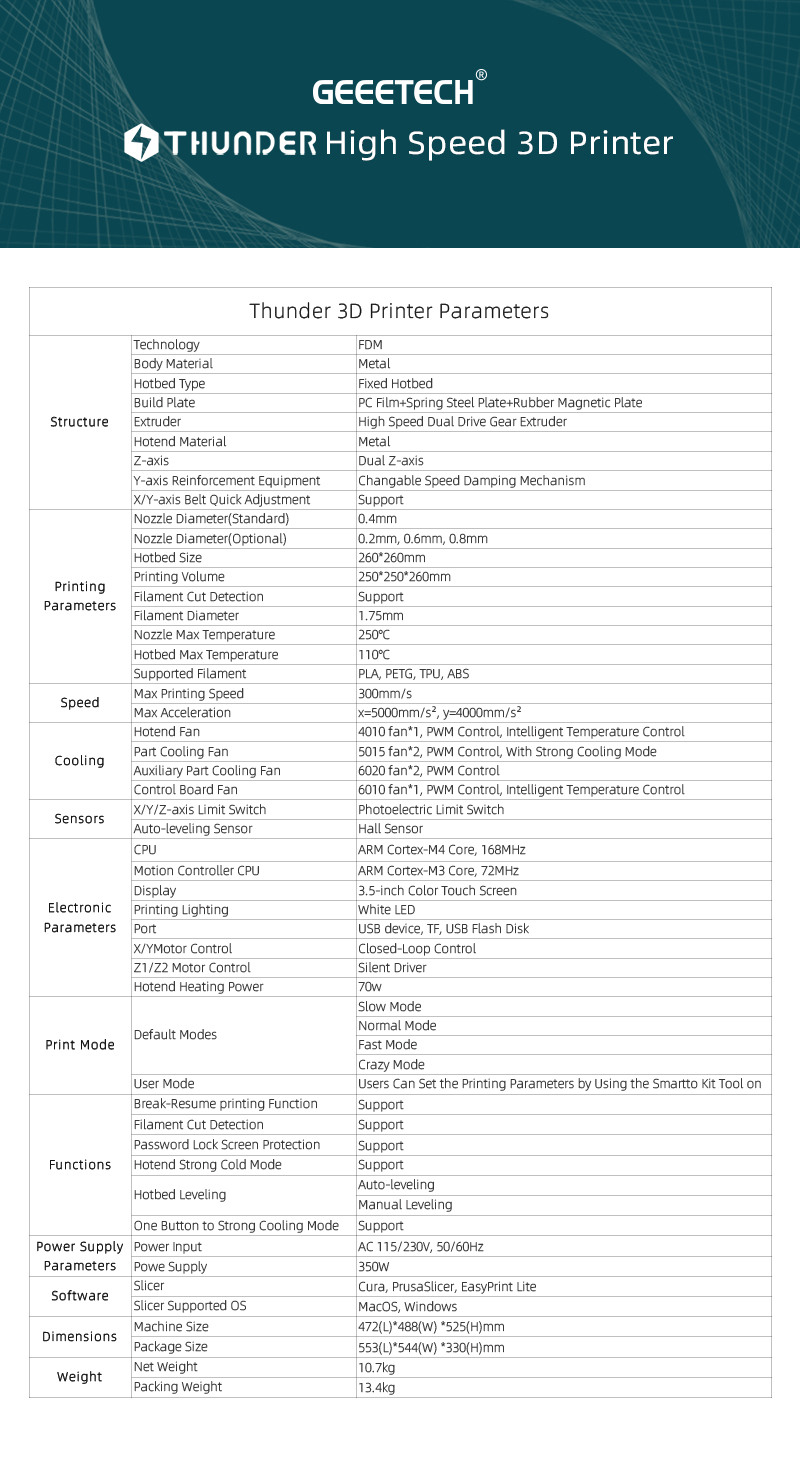

•Technology: FDM

•High speed printing, speed up to 300mm/s

•All metal body, stable and reliable structure

•Fixed hotbed, no more frequent leveling

•High speed dual gear drive extruder, excellent performance,stand wear and tear

•Motor control: X/Y axis adopts closed-loop drive control,Z axis adopts TMC2208 drive

•Dual Z-axis

•Strong cooling hotend fan: 4010*1, Part Cooling Fan: 5015*2, Auxiliary Part Cooling Fan: 6020*2

•Leveling: support manual leveling and auto-leveing

•Filament broken detection: standard packed with filament broken detection sensor

•Screen password protection: During the printing process, the screen is locked with a password to prevent the printing failure caused by the accidental change of printing parameters

•One button to strong cooling: one button to completely open the hot end fan and auxiliary part cooling fan

•Multi printing modes: Thunder inserted 4 printing modes for different speed level printing, meanwhile, it has a User Mode for users to customize printing parameters

•Break-resuming capability

•Printing lighting: Thunder designed a white LED light on the hotend, convenient for checking the nozzle and model condition

•Please read this document carefully to ensure that you understand each installation step, which will improve the efficiency of your assembly and reduce errors;

•Before starting the power supply, ensure that the voltage range of the power supply is consistent with the local voltage used by the user to prevent power damage;

•Please place the printer in a spacious, flat and ventilated environment. If you do not use the machine for a long time, please pay attention to waterproof and moisture-proof protection for the printer;

•Do not touch any moving parts while the printer is running to avoid personal injury;

•Do not touch the nozzle and hot bed when the printer is working, so as not to cause burns;

•When using the touch screen in the printing process, please pay attention to the movement of the hot bed to prevent the hot bed from hitting your fingers;

•Please use the printer in the environment of 10~40℃, otherwise the printing will be adversely affected;

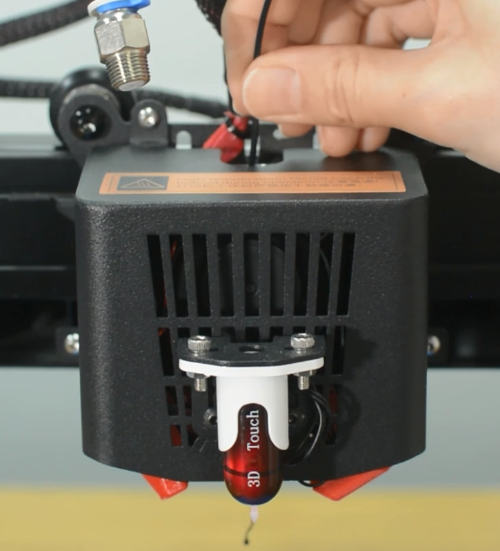

•Before using the 3D printer, please level the hot bed first. Thunder is equipped with 3D-Touch automatic leveling accessory. Please install the 3D-Touch before leveling the hot bed.You can also use manual hot-bed leveling if you do not have 3D-Touch installed.

Printer Maintenance

How to clean the hotend

1. Heat up the nozzle to 200 ℃, then remove the PTFE tube.

2. Use another piece of PLA filament to push through from the top to try to force the stuck filament in the nozzle out.

3. If you find that the hotend is still blocked, then you maybe able to use a small metal rod to push it in and out several times, making the clogging out. Do not use excessive force.

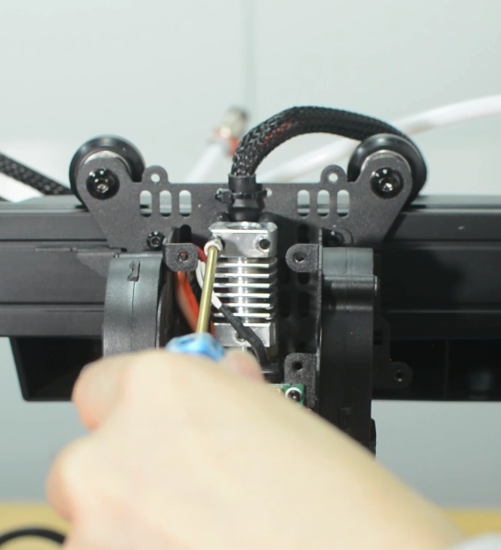

How to replace a nozzle

The nozzle is available in our website: 10 Pcs Nozzles for Thunder 3D Printer

1. Turn the printer off and unplug the power cable.

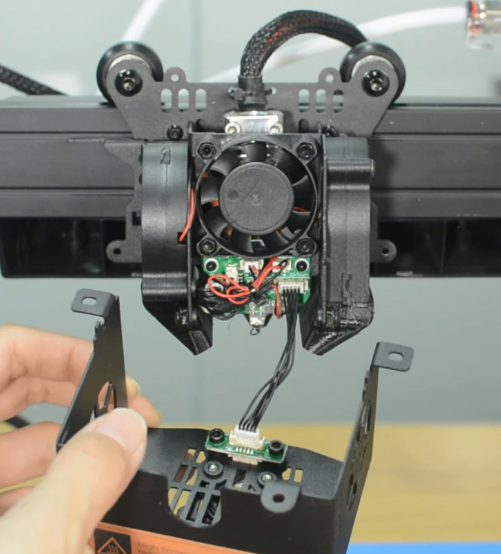

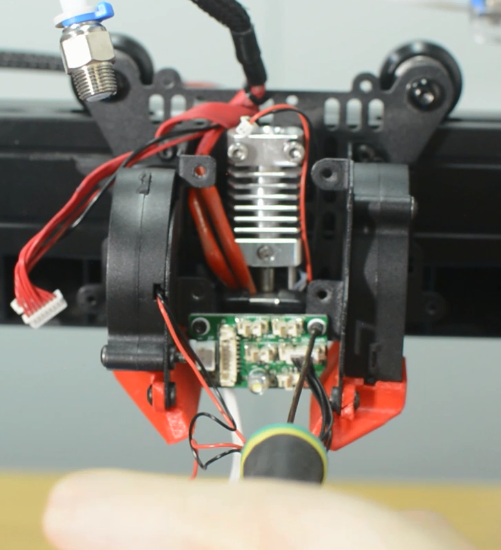

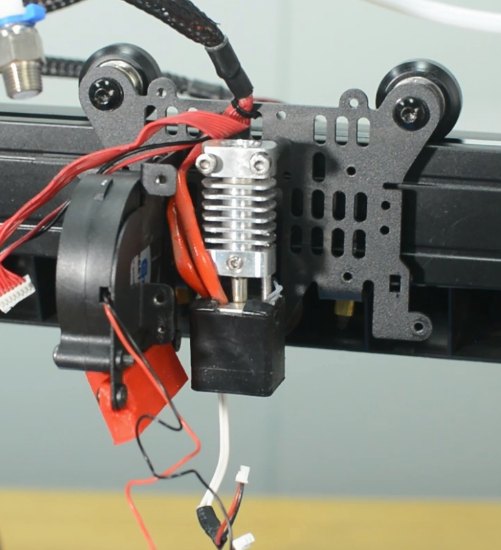

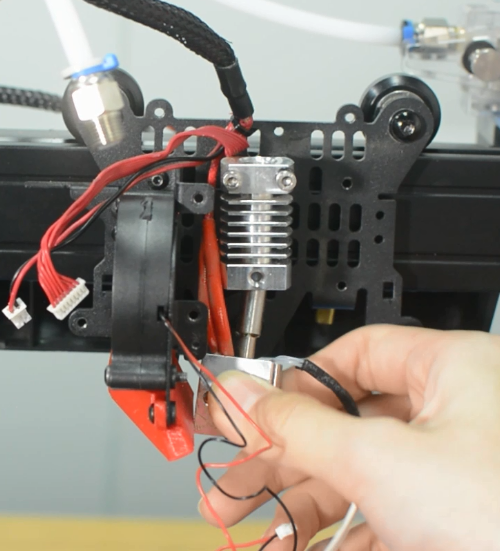

2. Remove the hotend housing, and one of the blower fans and its bracket.

3. Disconnect the cables of hotend cooling fan and the two blower fans.

4. Unscrew the extension board and put it aside.

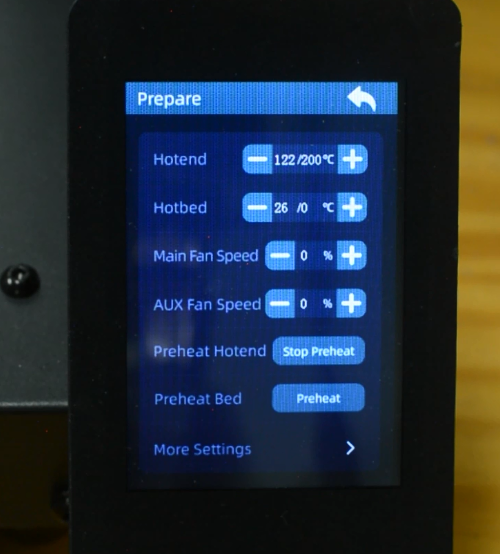

5. Turn the printer on and preheat hotend.

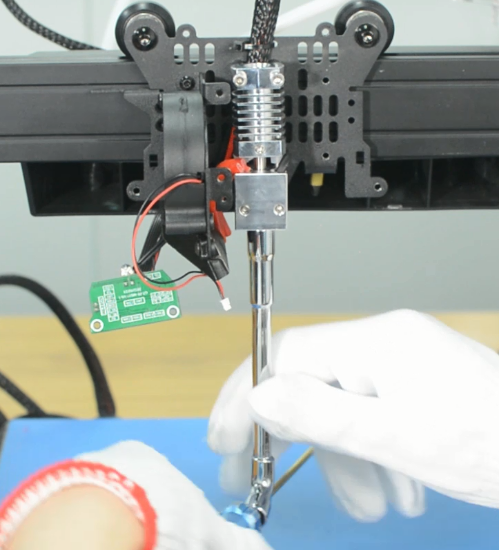

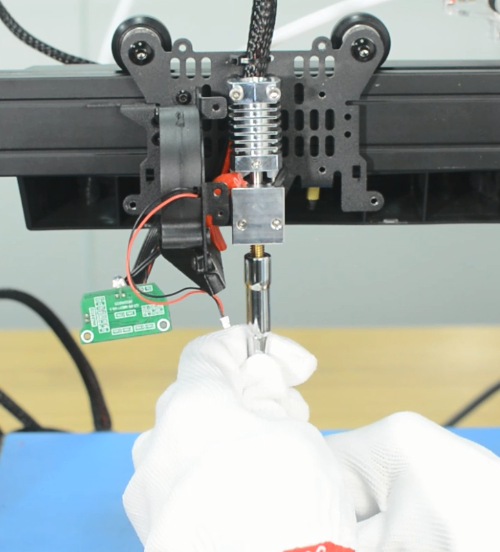

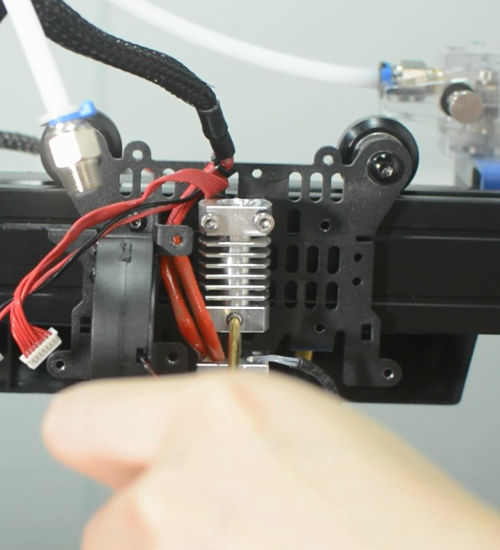

6. Wear gloves to prevent burns. Place the socket wrench vertically to unscrew the nozzle. Otherwise it is easy to misalign the screw and thread, causing the breakage of the nozzle in the heat block.

7. Place the socket wrench vertically to install the new nozzle. Do not use excessive force.

8. Place back all the pieces to reassemble the print head. It is done!

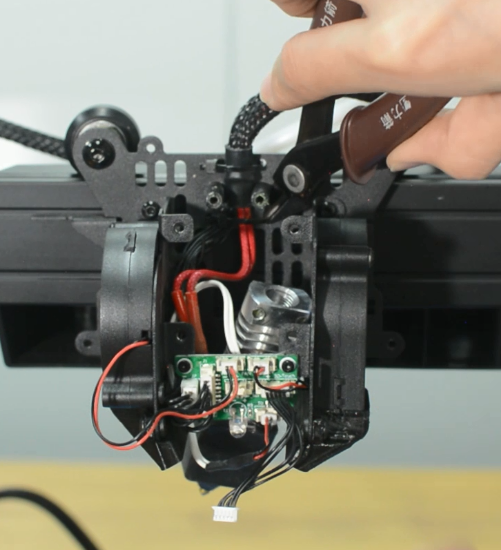

How to replace a heat block kit

The heater cartridge and hotend thermistor are available in our website: Thunder heater cartridge Thunder thermistor Thunder heat block kit

1. Disassemble the printhead partially.

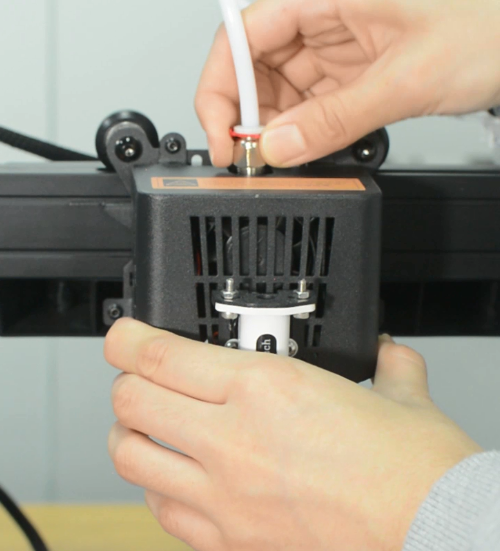

- a.Turn the printer off and remove the PTFE tube.

- b.Remove the hotend housing. Unplug all the cables from the extension board.

- c.Disassemble the extension board and the blower fan.

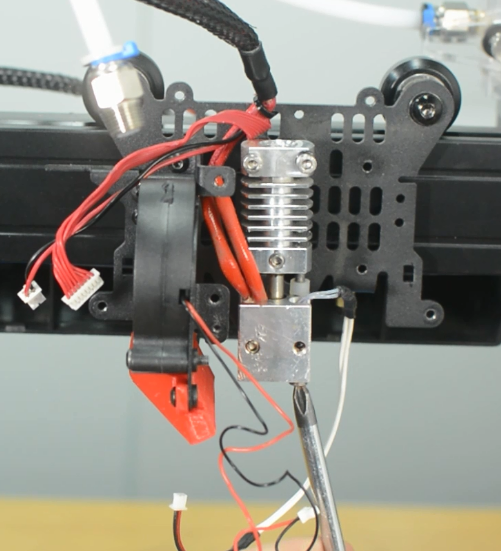

2. Remove the heat block kit.

- a.Release and remove the two screws that secure the heat block.

- b.Release the grub screw and remove the heat block.

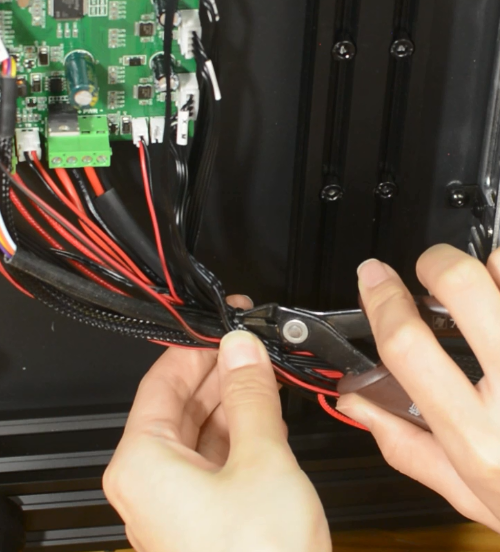

- c.Cut off the zip ties and be aware of not cutting the cables.

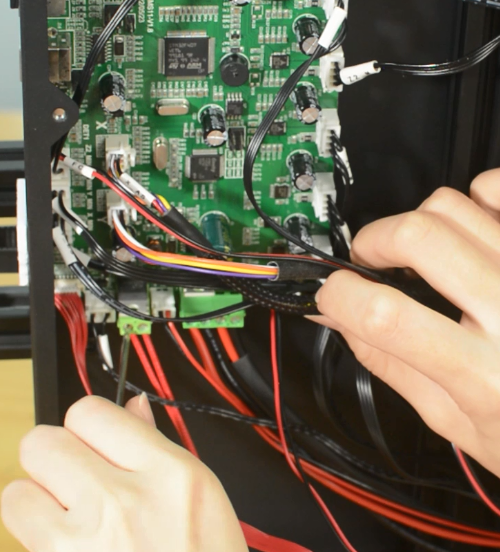

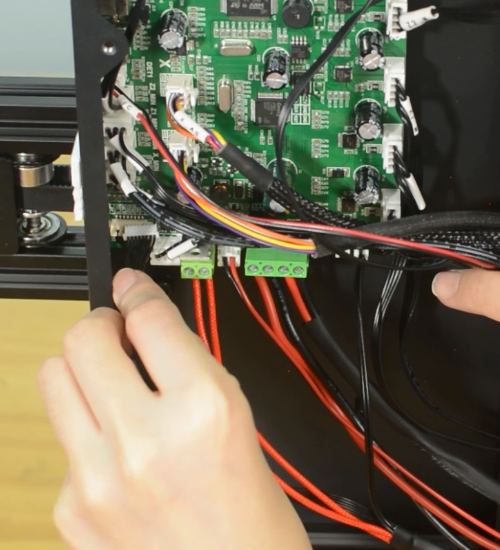

- d.Release the screw terminals for heater cartridge and remove the cables. Unplug the cables of hotend and the hotend fan.

- e.Remove the heat block kit completely from the printer and put it aside.

3. Install the new heat block kit.

- a.Install the new heat block to the below of the heat sink and tighten it by the two screws.

- b.Tighten the grub screw to secure the heatbreak.

- c.Place back all the pieces to reassemble the print head. Use zip ties to manage the cables.

- d.Place back all the pieces to reassemble the print head. Make sure the cables are fully inserted and tightened!

- e.Connect the cables for hotend fan and hotend.

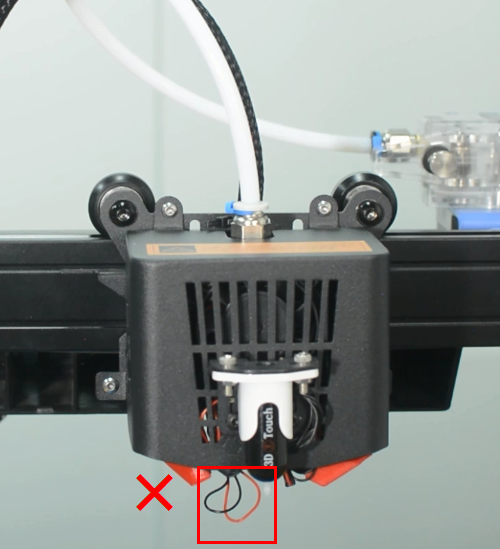

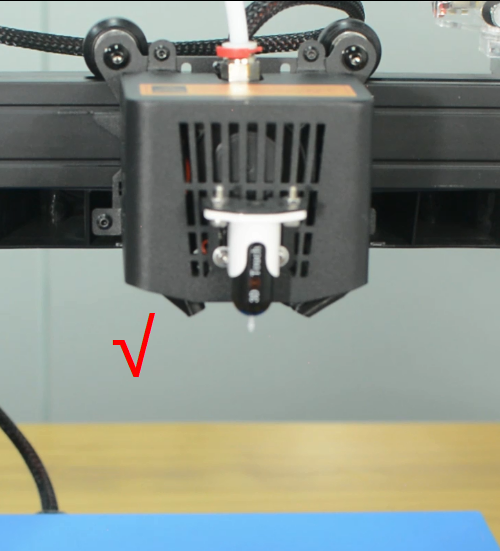

- Warning : Tie the wires properly, otherwise it will scratch the model during printing, leading the wires disconnected.

4. It's done. Heat up the printer and try it out.

How to replace a hotend

The hotend is available in our website: Thunder hotend

Prepare: Turn the printer off and unplug the power cable from the socket.

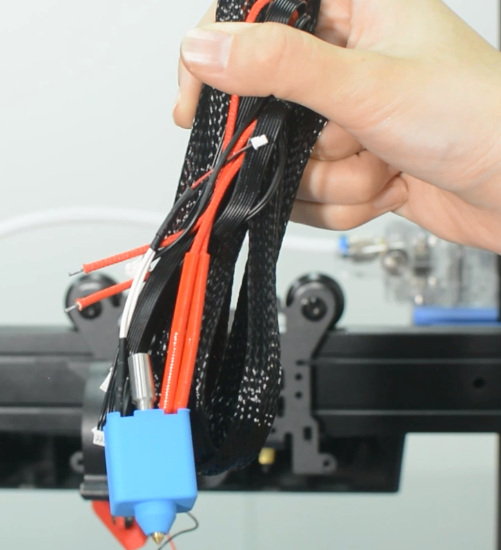

1. Disassemble the hotend kit

- a.Remove the PTFE tube and the hotend housing and disassemble the hotend fan.

- b.Release and remove the two screws that secure the hotend.

- c.Cut off the zip ties and be aware of not cutting the cables.

- d.Release the screw terminals for heater cartridge and remove the cables.

- Unplug the cables of hotend and the hotend fan.

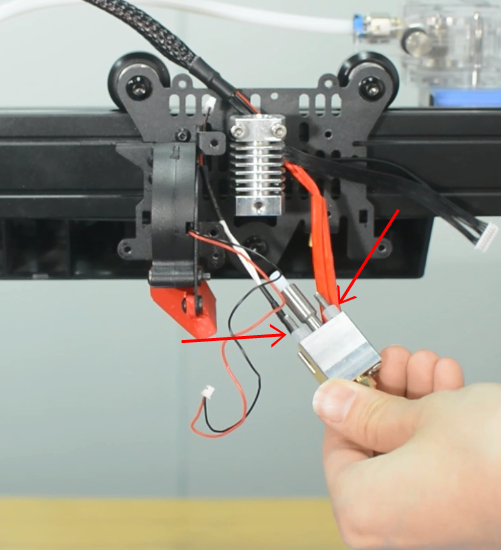

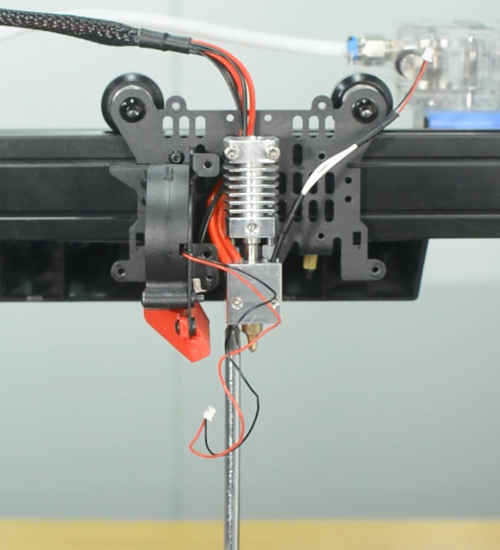

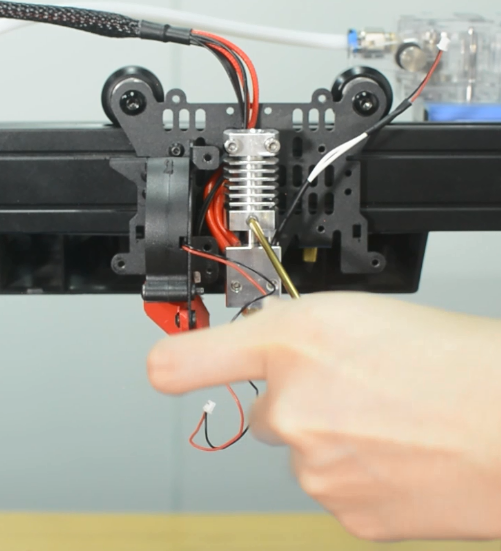

2. Install the new hotend kit

- a.Install the new hotend to the bracket.

- b.Connect all the cables for hotend. Install the hotend housing.

- c.Connect the cables of hotend fan and hotend.

- d.Insert the both heater cables into the connector and tighten the screw terminals. Make sure the cables are fully inserted and tightened!

3. It's done. Heat up the printer and try it out.

Trouble Shooting

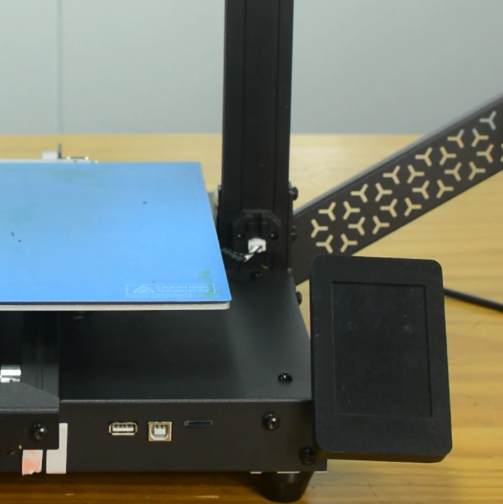

Turn the printer on but the screen is black

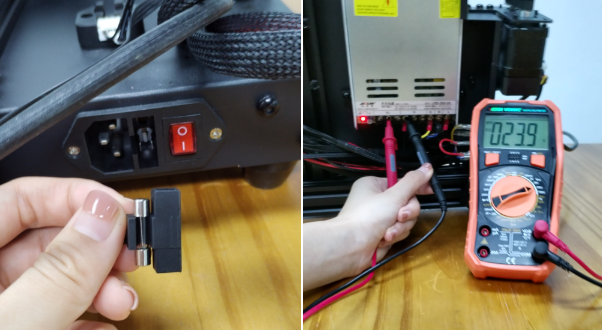

Warning: Never install or unplug anything on a printer while it’s being powered!

(a)Check if the power supply is working normally. The red indicator on the switch should be light. And also check the fuse in the little black box, it should be complete without burns. Please measure the output voltage, which should be around 24 Volts.

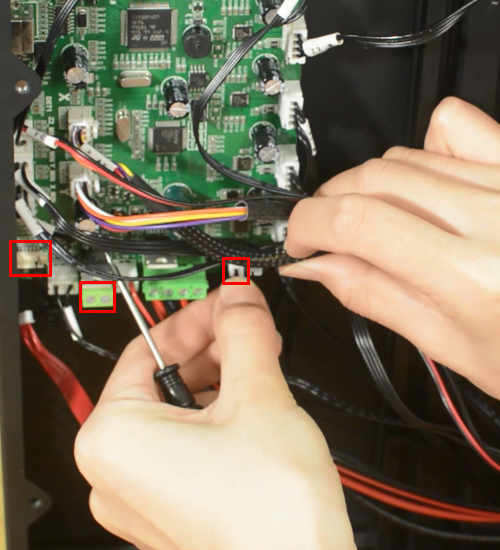

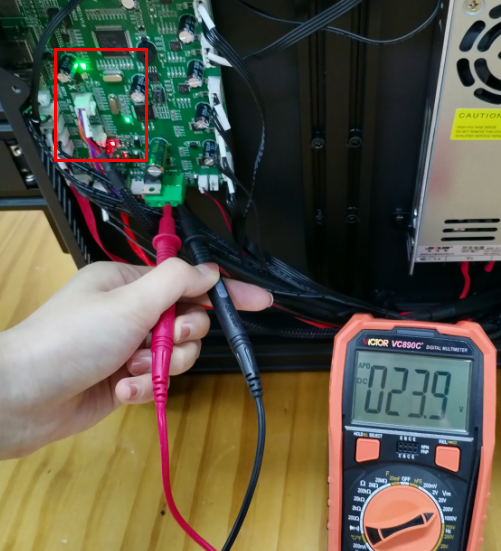

(b)Check if the control board is working normally. There’re two green LEDs and one red LED working as the picture shown below. Measure the input voltage of the control board, it should be around 24 Volts.

(c)Make sure the screen is connected properly.

The extruder keeps making a click sound

(a)Decrease the print speed. If the print speed is too fast, the extruder will push the filament too quickly. Filament may not have enough time to melt and even clog in the nozzle. A clogged nozzle will then exert pressure back on the extruder, resulting in clicking. For PLA, our recommended print speed is under 250 mm/s.

(b)Increase the print temperature. If the temperature is too low, it will not melt the filament properly. This can also clog the nozzle. As the extruder is no longer able to push the filament ahead, it starts “slipping”.

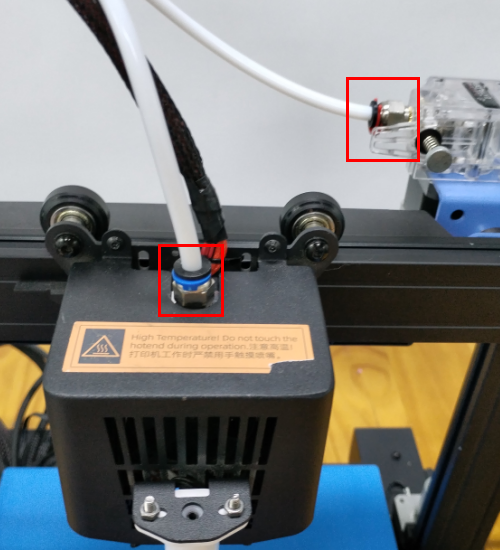

(c)Check the pneumatic fittings. A loose coupling could therefore allow molten filament to leak into a gap between the tube and the nozzle. This will restrict the flow of the filament, causing the extruder keep clicking.

(d)Change the extruder gear. After many hours of use, the teeth of the extruder may eventually wear out. Thus, it can no longer hold the filament, leading to filament slipping in the extruder.

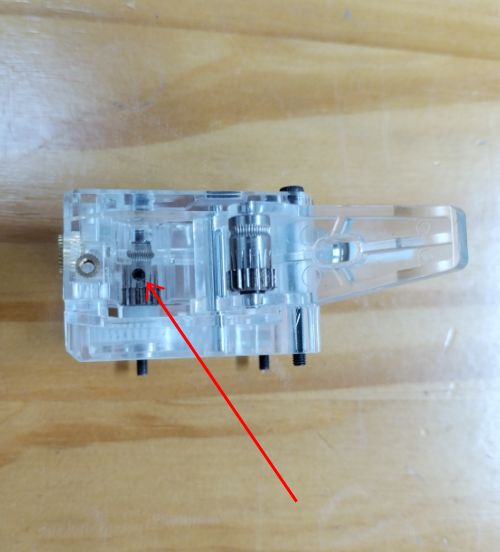

(e)A low-tension extruder arm bar. If spring tension is too low, the extruder gear will not properly grip the filament. This leads to filament grinding.

(f)Check if the grub screw on the extruder gear. If the grub screw is loose, the gears will fail to grab the filament.

Nothing is printing

(a)Nozzle is too close to the hotbed

Even though the extruder is working but no filament is depositing on the hotbed, Check if the nozzle is too close to the hotbed. Adjust the Z-offset value slightly will help.

(b)Print temperature is too low

Some filament needs more higher temperature, manually feed the filament, if it can not be extruded, please try increase the print temperature.

(c)The extruder is not working

Check if the grub screw on the extruder gear. If the grub screw is loose, the gears will fail to grab the filament when feeding into the hotend. Also check if the extruder motor is connected properly.

Mintemp error

The Mintemp error in 3D printers is a design feature within your firmware for safety in regard to temperature. When below a set temperature, the heater will be switched off due to possibly having a broken thermistor wire. It can be observed a negative the temperature on the LCD screen.

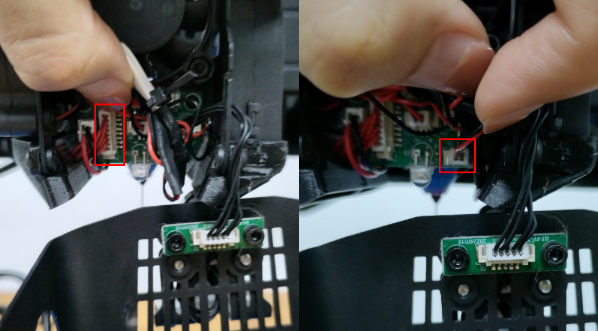

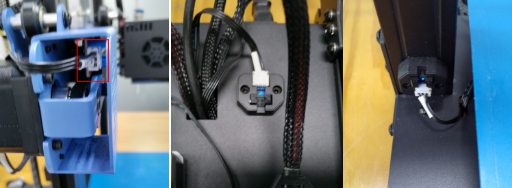

Check if the hot end connector and thermistor are connected properly as the pictures below. Check the hotend cables and thermistor, make sure they’re not broken or burn out.

You can test the thermistor by a multimeter. If it fails to read the resistance, then the wire is broken. At room temperature, it should be 80 kΩ - 125 kΩ. Or apply heat to the thermistor with a heater, blow-dryer or other heating device.

The resistance should decline steadily in seconds if it works. If not, replace it.

Another common reason behind getting the MINTEMP error is from being in a cold environment, especially in winter months. Your 3D printer is designed to have a minimum temperature that it can operate in as a safety feature.

Automatic leveling failed

(a)3D Touch is abnormal

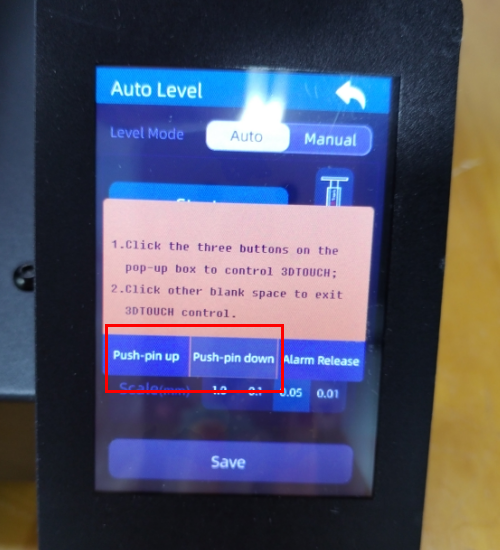

Check if the 3D Touch cables are connected properly. You can use the “Test” function to check if the 3D Touch is working normally.

(b)Homing failed

Check the X, Y and Z axes end stops, make sure they’re all connected properly. Note the photoelectric end stops on the Y and Z axes, which normally have a blue signal light. You can home the X, Y and Z axes one by one to check which axis is faulty.

Also check the X and Y axes closed loop motor connections.

(c)The first layer is messy

Please clean the hotbed before printing, this will help to get a good adhesion. We recommend a thicker first layer, 0.3 mm is good. If these’re not helpful, please try to adjust the Z-offset. What’s more, you can try adjust the hotbed temperature, for example, the Geeetech wood PLA needs a lower hotbed temperature but PETG needs higher.

Spring steel sheet problem

The spring steel sheet is flexible and easy for part removal. But keep in mind that prints are easy to remove after the plate cools down. Don’t try to forcefully remove the object when the sheet is still hot. We do not suggest you use the adhesive on the sheet, because the adhesive is difficult to clean up and may have an opposite effect.

If there’re leftover residue on the sheet, preheat the hotbed to 80 degrees to make the plastic soft. Then use the wet cloth wiping the plate and gently scrap the residue off.

A dirty bed will cause poor first layer adhesion. You need to remove the dirt, leftover residue or oil from the bed surface. Isopropyl alcohol (IPA) 90%+ will help to degrease the platform.

Filament sensor

If there’s error on the screen prompts like “Change Filament” even filament has been uploaded, maybe the sensor is broken. You can test it by a multimeter.

Remember load a small piece of filament through the sensor before test. By touching each of the measurement leads of the multimeter to the two pins of the sensor, a signal (beep or 0 value on the multimeter screen) will indicate that the component is intact and therefore, should work.

Nozzle discharge abnormality

1. Filament is knotted and stuck, and the feeding is not smooth.

2. The nozzle temperature is too low and does not reach the required melting temperature of filament.

3. There is carbonization residue in the nozzle, please replace the spare nozzle.

4. The heat dissipation of the nozzle is insufficient, resulting in the filament in the upper part of the pipe melting in advance, and the extrusion force is insufficient. Please check whether the cooling fan works normally.

5. The printing speed of model slices is too fast, and the nozzle extrusion speed cannot keep up with it. Please reduce the speed.

6. If the nozzle extrusion is not smooth due to scraping, please use the nozzle cleaner to dredge the nozzle after preheating.

The extruder gear slips and makes abnormal noise

1. Nozzle blocking, refer to the "nozzle discharge abnormality" treatment.

2. Check whether the friction force of extruder gear to filament is enough, please clean up the gear residue.

First layer abnormal

1. The first layer does not stick: the nozzle is too far away from the hot bed, please adjust the hotbed leveling again.

2. The first layer is not discharging, and the hot bed has scratches: the nozzle is too close to the hot bed, which is easy to damage the nozzle. Please level it again and check whether the discharging of the nozzle is normal.

Layer shift

1. The printing speed of model slices is too fast, please reduce the printing speed.

2. The belt of X axis or Y axis is too loose, please adjust the belt tightness.

3. X axis or Y axis synchronization wheel is not secured, please adjust the machine meter on the synchronization wheel.

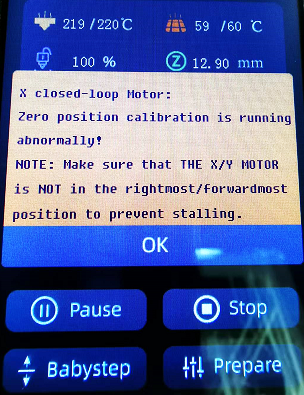

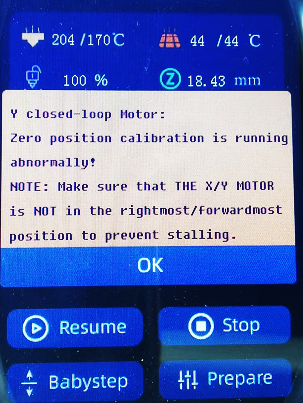

X/Y axis Closed-loop Control Abnormality

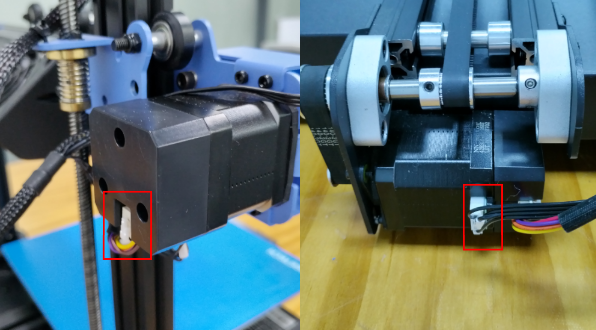

During the using of THUNDER, if the X-axis or Y-axis is stuck in the process of movement, it may be caused by the following two reasons after excluding the non-pulley structure and improper connection of wiring:

1. The X-axis motor or Y-axis closed-loop control sensor is not calibrated or the calibration parameters fail, the closed-loop control sensor of the corresponding axis needs to be re-calibrated.

2.The magnet of the closed-loop control unit of the X-axis motor or Y-axis motor is loose or falls off. The magnet needs to be fixed on the motor shaft with glue again.

=='Filament'==

Does Thunder require high-speed PLA filament to achieve high-speed printing?

No, Thunder is designed to achieve high-speed printing with ordinary PLA filaments, so Thunder can achieve high-speed printing with ordinary PLA filaments.

G-code for part cooling fan and auxiliary part cooling fan

Part Cooling Fan:

M106 P0 S383 ; ON MainFan 150%

M106 P0 S255 ; ON MainFan 100%

M106 P0 S128 ; ON MainFan 50%

Auxiliary Part Cooling Fan:

M106 P1 S255 ; ON Aux Fan 100%

M106 P1 S128 ; ON Aux Fan 50%

M106 P1 S0 ; OFF Aux Fan