Filament

Contents

PLA

Polylactic acid, commonly referred to as PLA, is made from natural materials such as corn starch. It’s the most widely-used filament in the 3D printing industry. PLA isn’t a plastic known for its strength compared with PETG or ABS, and it’s brittle and stiff compared with TPU. But it’s easy to print, does not need an enclosure or a direct drive extruder. It’s cheap, widely accessible and it can be printed more quickly than most other filament.

As for Geeetech PLA, the perfect settings in Cura slicer is shown as below:

Nozzle temperature: 180-220 °C

Bed temperature: 60-70 °C

Print speed: 60-100 mm/s

Initial layer height: 0.3 mm

Initial layer print speed: 20 mm/s

Travel Speed: At least 120 mm/s

Retraction distance: 6 mm for Bowden setups, 2-3 mm for direct drive setups

Retraction speed: 45 mm/s

Cooling fan speed:100%

Initial layer cooling speed: 0%

Build plate adhesion: Skirt or Brim

If you want to test the most suitable print temperature, download the temperature tower model below.

The PLA temperature tower is available in our website.

Geeetech Filament Storage Vacuum Bag

PLA not sticking to the hotbed

(1) Level the hotbed

In order to get a perfect first layer, make sure the printing platform is flat and level. That’s to say, the nozzle should be the same distance above the hotbed at all points. Manual leveling or automatic leveling will help you achieve this.

(2) Change the Z-offset

Z-offset is the distance between the nozzle and Z axis home position. A bad Z-offset can cause the nozzle either too close or too far from the hotbed, that will make a bad influence on how PLA is deposited on the bed.

(3) Clean the hotbed

A dirty bed will cause poor first layer adhesion. You need to remove the dirt, leftover residue or oil from the bed surface. Isopropyl alcohol (IPA) 90%+ will help to degrease the platform.

(4) Adjust the slicer settings

Small prints will likely to detach from the hotbed because of the small contact area. Using a brim or raft in the slicer will be helpful to this problem. And we recommend the first layer height set to 0.3mm, print at 25mm/s.

Silk PLA keeps clogging

Silk PLA owes its glossy look to some elastic additives. It is easy to 3D print, but the elastomers can sometimes cause clogging issues and under extrusion.

We recommend you print the PLA temperature tower for every different silk PLA. For example, silk green will string a lot when the temperature is higher than 200 degrees, but the silk sliver will get its best properties at 220 degrees.

Luminous PLA not able to shine as expected

You need “charge” the prints under UV light before they will glow in the dark. The glow lasts about 2-3 minutes.

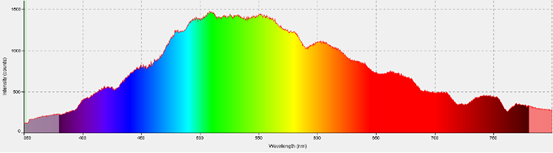

Geeetech Luminous Multicolor PLA is a color change every 13 meters based on the three primary colors of red, green and blue. There will be a color gradient at the intersection of the color change, in which the wavelength of green light (520_570nm) is in the center of the visible spectrum, as shown in the figure below:

Consider printing with thick walls and little infill for best results: the thicker your walls, the stronger the glow. But be aware, these blends tend to also be more abrasive compared to your standard PLA, so better check your 3D printer nozzle.

Among luminous PLA of various colors, luminous green PLA has the best effect, because luminous powder is added and its main component is fluorite that glows green. It is recommended to increase the UV exposure time in order to get the best effect.

The luminous PLA is not as easy as standard PLA to stick to the hotbed, please increase the hotbed temperature to 70-75 degrees and make sure you have a clean and leveled hotbed before printing.

Wood PLA keeps clogging

Wood PLA is made by combining polylactic acid and fibers of different types of wood, such as willow, bamboo, cork, cedar, and more.

Geeetech wood PLA contain about 85% PLA and 15% wooden fibers.

We suggest you should use 0.4 mm or larger nozzles, otherwise, the wood particles might clog up the nozzle.

The recommended print temperature is 180-190 degrees, hotbed temperature is 40-60 degrees.

Carbon Fiber PLA

PLA carbon fiber filaments are a composite material, usually made of a mixture of polylactic acid (PLA) and carbon fiber. At the same time, PLA carbon fiber filaments have the following characteristics:

High strength and high rigidity: Combines the easy printability of PLA with the high strength and rigidity of carbon fiber.

Printing performance: It has good printing performance, less warping and shrinkage, and is easy to control.

When using PLA carbon fiber filaments, things to pay attention to: Nozzle selection: It is recommended to use a nozzle of 0.4 mm or larger to avoid clogging.

Printing temperature: The nozzle temperature is maintained at 200°C to 230°C, and the hot bed temperature is set at 50°C to 60°C to avoid material clogging or printing quality problems

Humidity control: Use sealed bags and desiccant when storing to prevent moisture absorption from affecting printing quality.

Clean the nozzle: Clean the nozzle and extruder regularly to prevent carbon fiber particles from accumulating.

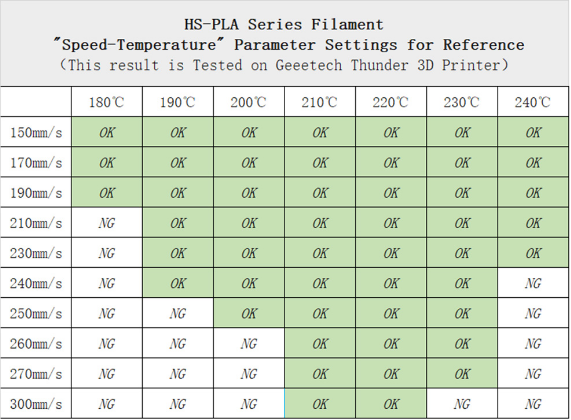

High Speed PLA

High speed PLA has a much faster flow rate than regular PLA before under extruding.

By adjusting the melting point/index, glass transition temperature of raw materials and optimizing the production process, Geeetech enables HS-PLA to have stronger fluidity, smoother discharge, faster curing and forming speed and is not easy to deform under the melting condition.

PETG

Polyethylene terephthalate glycol, most commonly known as PETG, is a widely-used material in 3D printing. It’s a durable, non-toxic, low-shrinkage and sturdy material that’s suitable to use in outdoors. But remember PETG is hygroscopic. Try using a container or resealable bags.

As for Geeetech PETG, the perfect settings in Cura slicer is shown as below:

Nozzle temperature: 220-230 °C

Bed temperature: 70-80 °C

Print speed: 40-50 mm/s

Initial layer height: 0.3 mm

Initial layer print speed: 20 mm/s

Travel Speed: At least 120 mm/s

Retraction distance: 6 mm for Bowden setups, 2-3 mm for direct drive setups

Retraction speed: 25 mm/s

Cooling fan speed: 30-40%

Initial layer cooling speed: 0%

Build plate adhesion: Brim

The PETG Cura profile, PETG temperature tower and fan tower are available in our website

Geeetech Filament Storage Vacuum Bag

ABS

Acrylonitrile butadiene styrene (ABS) is commonly found in household and consumer products. ABS is strong, tough, and durable. It has good resistance to heat and impact. Toxic fumes are released while printing ABS, you’ll need an enclosure or in a properly ventilated room.

As for Geeetech ABS, the perfect settings in Cura slicer is shown as below:

Nozzle temperature: 230-250 °C

Bed temperature: 80-100 °C

Print speed: 40-50 mm/s

Initial layer height: 0.3 mm

Initial layer print speed: 20 mm/s

Travel Speed: At least 120 mm/s

Retraction distance: 6 mm for Bowden setups, 2-3 mm for direct drive setups

Retraction speed: 25 mm/s

Cooling fan speed: 0%

Initial layer cooling speed: 0%

Build plate adhesion: Brim

ABS is a hygroscopic material. High moisture content in the filament leads to poor layer adhesion and brittleness. This results in a 3D printed part that can break away easily. Dry boxes and plastic vacuum bags offer a great way to store your materials.

Geeetech Filament Storage Vacuum Bag

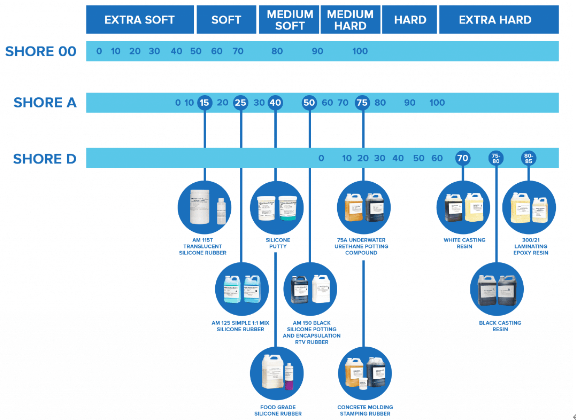

TPU

TPU stands for “thermoplastic polyurethane”. TPU is a specific type of TPE and is on the more rigid than other flexible filaments, making it easier to print with. The Shore hardness value of Geeetech PLA is 95A. You will need TPU if your print always bends, stretches or compresses.

As for Geeetech TPU, the perfect settings in Cura slicer is shown as below:

Nozzle temperature: 200-210°C

Bed temperature: 60 °C

Print speed: 30-40 mm/s

Initial layer height: 0.3 mm

Initial layer print speed: 20 mm/s

Travel Speed: At least 120 mm/s

Retraction distance: 6 mm for Bowden setups, 2-3 mm for direct drive setups

Retraction speed: 25 mm/s

Cooling fan speed:100%

Initial layer cooling speed: 0%

Build plate adhesion: Brim

Geeetech Filament Storage Vacuum Bag

Applicable to Bambu Lab AMS LITE

GEEETECH consumables can be used with this bracket on the Bambu Lab AMS Lite system

https://drive.google.com/file/d/1KqEPtpktfTxeXTFFHBS_HanhLsq7SxzY/view?usp=drive_link

Solution for consumables entangled with each other

For the problem of consumables being intertwined, here are some solutions:

1.Separate the entangled parts: Separate the entangled parts of the filament one by one, and operate carefully to ensure that the filament will not be further entangled or damaged.

2.Rewind the filament: Rewind the separated filament, ensuring that it is wound in the clockwise direction of the outer ring of the filament. Avoid random or reverse winding to avoid causing the filament to stagger or become entangled again.

3.Use appropriate tools: You can use appropriate auxiliary tools to help rewind the filament to ensure more precise and stable operation.

4.Adjust the position of the filament: Make sure that the filament reel on the printer is in the correct position and will not interfere with the normal supply and winding of the filament.

5.Regular maintenance and cleaning: Regularly clean the printer’s filament path and surrounding area to ensure that no accumulated dust or debris affects the normal operation of the filament.

6.Youtube video link address: https://youtube.com/shorts/6L3DUEzIdVY?feature=share