Difference between revisions of "Geeetech GTM32 Board"

(→Quick Start) |

(→Features) |

||

| Line 29: | Line 29: | ||

i. With a buzzer on board. | i. With a buzzer on board. | ||

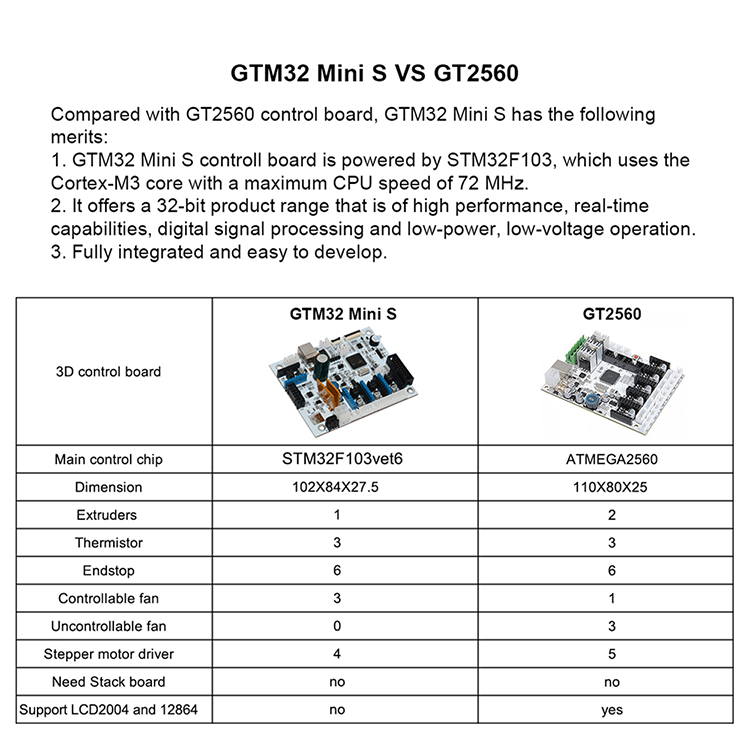

| − | [[File: | + | [[File:04对比表格.jpg]] |

=Hardware Resources= | =Hardware Resources= | ||

Revision as of 05:53, 25 May 2018

Contents

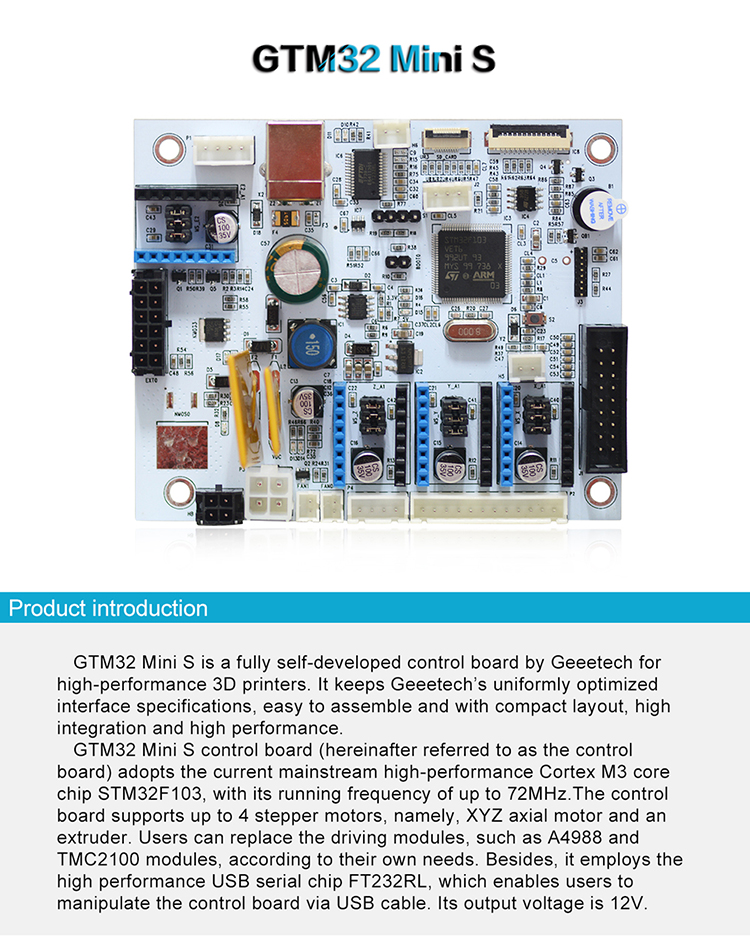

Introduction

GTM32 is a fully self-developed control board by Geeetech for high-performance 3D printers. It keeps Geeetech’s uniformly optimized interface specifications, easy to assemble and with compact layout, high integration and high performance.

GTM32 control board (hereinafter referred to as the control board) adopts the current mainstream high-performance Cortex M3 core chip STM32F103, with its running frequency of up to 72MHz.The control board supports up to 4 stepper motors, namely, XYZ axial motor and an extruder. Users can replace the driving modules, such as A4988 and TMC2100 modules, according to their own needs. Besides, it employs the high performance USB serial chip FT232RL, which enables users to manipulate the control board via USB cable. Its output voltage is 12V.

Features

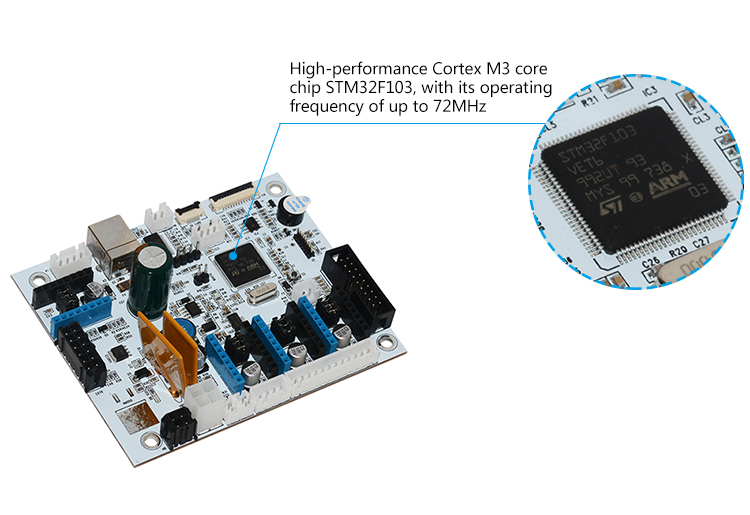

a. Adopting high-performance Cortex M3 core chip STM32F103, with its running frequency of up to 72MHz.

b. Using high-performance USN serial chip FT232RL, manufactured by FTDI, compatible with Windows, OS X, Linux etc. mainstream operation system.

c. The output voltage of GTM32 control board is 12V. It is characterized by dual power supply design, powering up the hotbed and other electronic components respectively. The current for hotbed is 9A and 7A for other parts.

d. The main circuit adopts in-line fuse, with overcurrent protection and reverse protection. The USB power supply interface has a restorable fuse, with its current at 500mA.

e. The control board features three interfaces for PWM fans.

f. Supporting up to 4 stepper motors, namely, XYZ axial motor and an extruder. The common stepper motor drivers are A4988 and TMC2100.

g. Three temp sensor inputs: one for the extruder, the second one for the hotbed and the third one for expansion. 100K thermistor is recommended.

h. The control board comes with expansion interfaces for LCD display and SD card, supporting stand-alone printing.

i. With a buzzer on board.

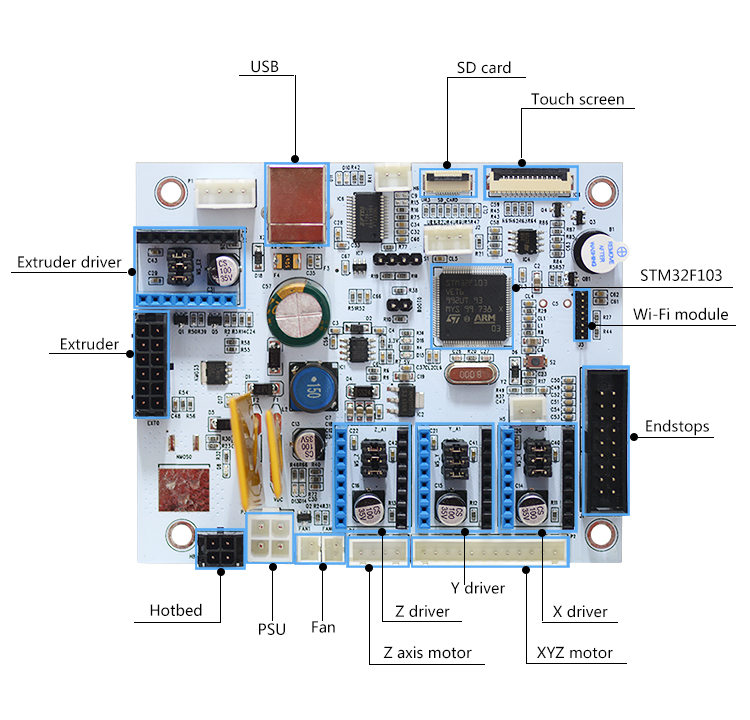

Hardware Resources

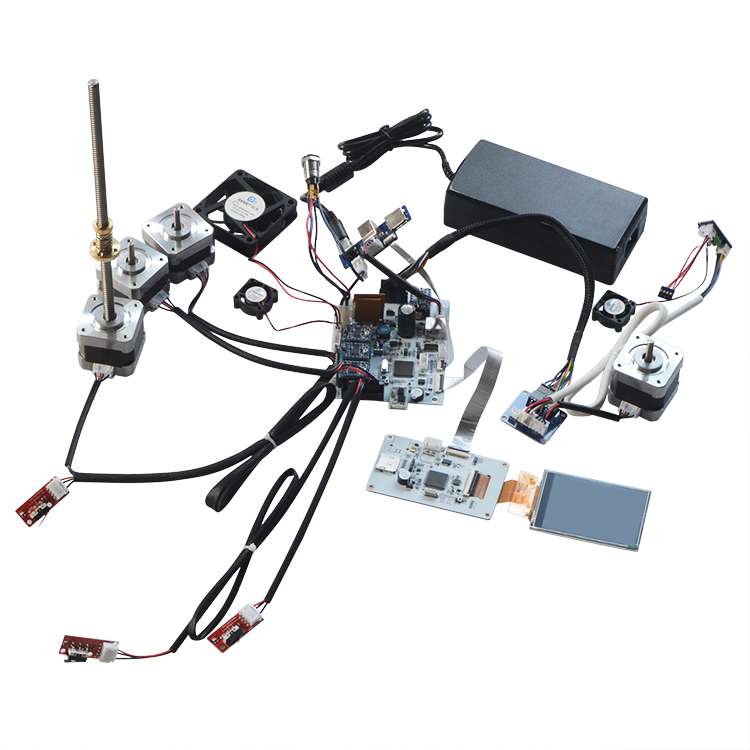

Here is a list of the hardware for GTM32 control board.

1. Power supply unit: 12V output voltage

2. Hotbed interface and extruder interface

3. 4 stepper motor drivers (3 for X, Y, Z axis motors and 1 for the extruder)

4. Interfaces for LCD display & SD card.

5. 6 endstop interfaces

6. 3 interfaces for thermistor

7. 3 interfaces for PWM fan

8. 3D Touch interface

9. Serial interface for Wi-Fi module

Diamension: 102mm*84mm* 27.5mm

Weight: 79.00 g

Interface specifications:

Extruder interface: MX (3.0mm-2*6Pin)

Hotbed interface: MX (3.0mm-2*2Pin)

X, Y, Z motor interfaces: XH (2.54mm-12Pin)

Control board Fan interface: PH (2.00mm-2Pin)

Endstop interface: 2x9 Pin (2.54mm -18Pin)

3D Touch interface: XH (2.54mm-2Pin, 3Pin)

Serial interface for Wi-Fi module: 1x8Pin (1.27mm-8Pin)

USB interface: USB B type

LCD interface: FPC1.0mm-12 Pin

SD card interface: FPC0.5mm-10 Pin

Software resources

3D Printing and control software:

Interfaces

Interface Layout

Introduction to the Interfaces

1. PSU: output voltage 12V

2. Hotbed interface:

1, 2 for hotbed; 3,4 for the wire of measuring hotbed temp.

3. Extruder interface:

1, 2, 11, 12 for extruder motor; 3,4 for extruder fan and air blower; 9, 10 for filament sensor; 5,6 for the wire of heating the extruder; 7, 8 for the wire of measuring extruder temp.

4. LCD / Touch screen display interface: connected with LCD/touch screen display module

5. SD card interface: connected with SD card module

6. Endstop interface: X_min/X_max, Y_min/Y_max, Z_min/Z_max

1, 2, 3 for Z_min; 16, 17, 18 for Z_max; 4, 5, 6 for Y_min; 13, 14, 15 for Y_max; 7, 8, 9 for X_min; 10, 11, 12 for X_max.

7. XYZ motor: connected with the stepper motor for each axis (the sequence can be found on the back of the board).

8. Fan interface: for PWM fan, PH2.0-2 pin

9. USB interface: Connecting the USB cable with your computer.

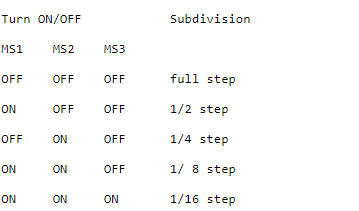

Subdivision of Stepper Motor

Use jumper caps to subdivide stepper motor. When jumper cap is plugged, it is ON.

X,Y,Z axis stepper motors

Extruder stepper motors

Detailed settings are as follows.

Subdivision on the basis of A4988 stepper driving module.

Development Environment Setting

Interface Connecting and Setting

Note:

Pay attention to the Plus-n-Minus of the power connector, reverse connection can cause irrevocable damages.

A4988 should also be connected to the right port, mismatches and revered directions can cause damage to the main board. Please notice the color of the pins and connect the same colored pins together. If some pins are not color-labelled, pleased follow the picture below.

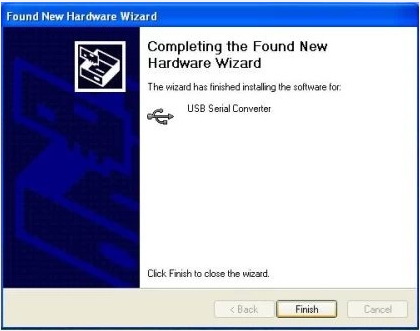

Install FT232RL Driver

After downloading, double-click the .exe file to finish the installation.

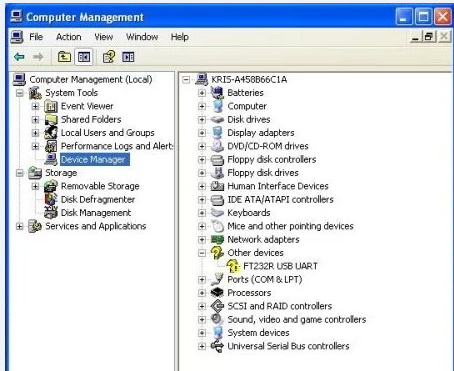

Windows will prompt that a new USB Serial Port is detected, now you can check the device manager, you will see a new port named“USB Serial Port”

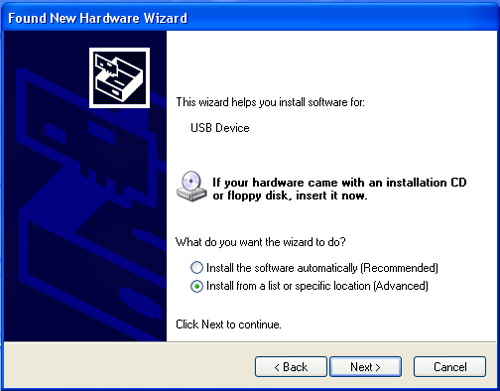

Then, windows will open the dialog box “found new hardware wizard”, check “no, not this time”, then click “next” to continue.

Then, windows will open the dialog box “found new hardware wizard”, Check “install from a list or specific location (advanced)”, then click “next”.

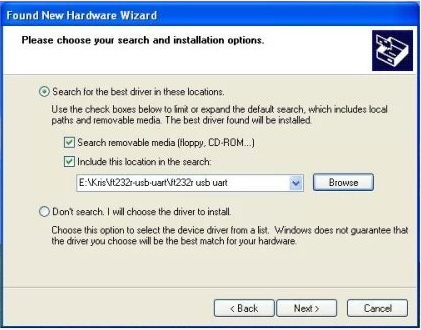

Specify installation directory where FT232RL is to install driver. Click “browse” to find the directory and click “next” to continue.

If everything goes well, windows will install the Serial Driver for GTM32.

The graph below shows installation completed.

Now, you can find the corresponding Serial port in device manager of windows.

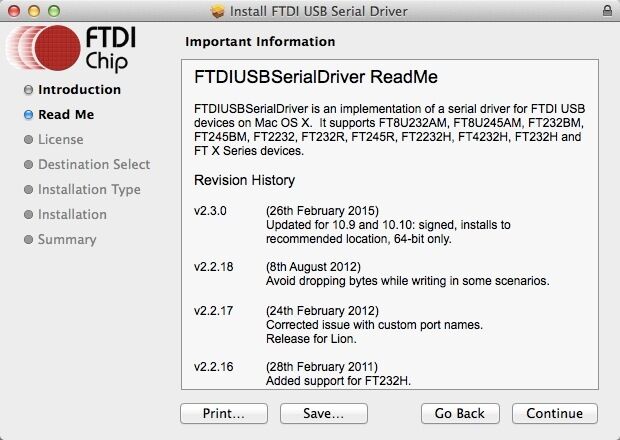

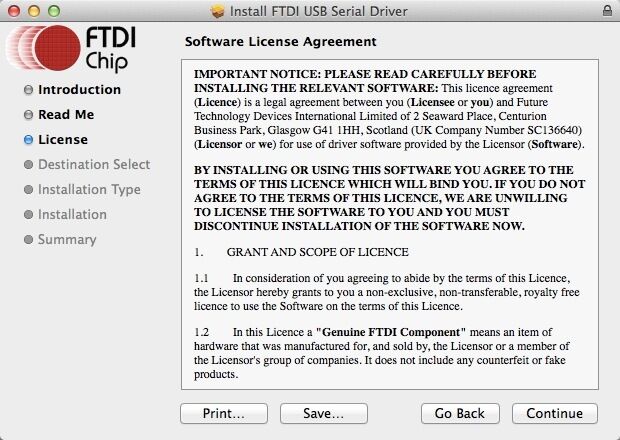

In Mac, you have to manually install the driver

Download link of driver: http://www.ftdichip.com/Drivers/VCP.htm

Download the driver that is compatible with system version.

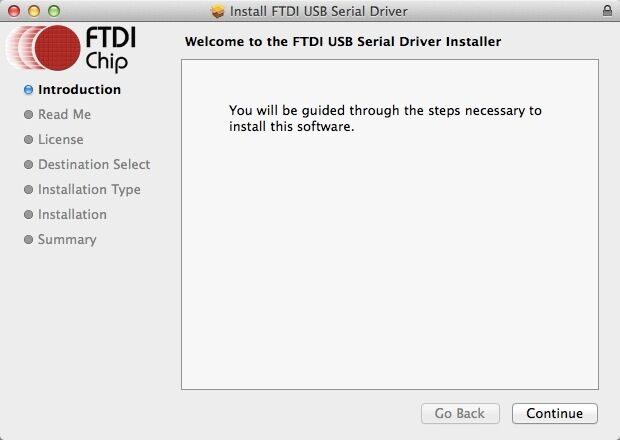

Open the downloaded file, you will see a .pkg file, Open "FTDIUSBSerial.pkg"

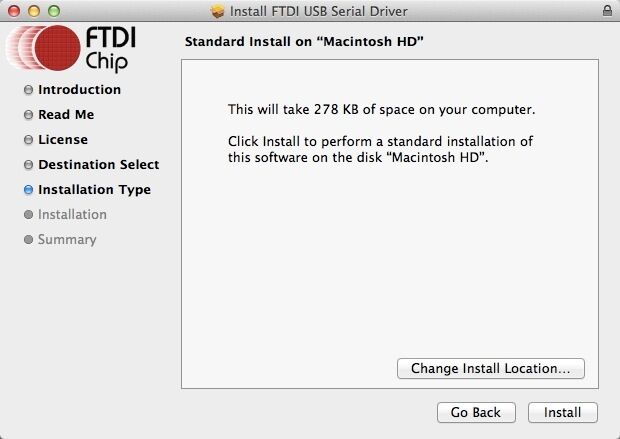

Click "Continue" in Instruction.

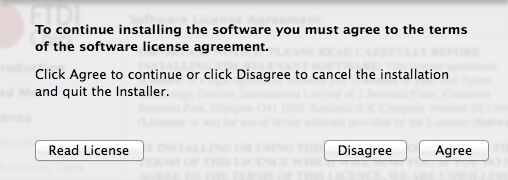

Click "Agree" to continue installation.

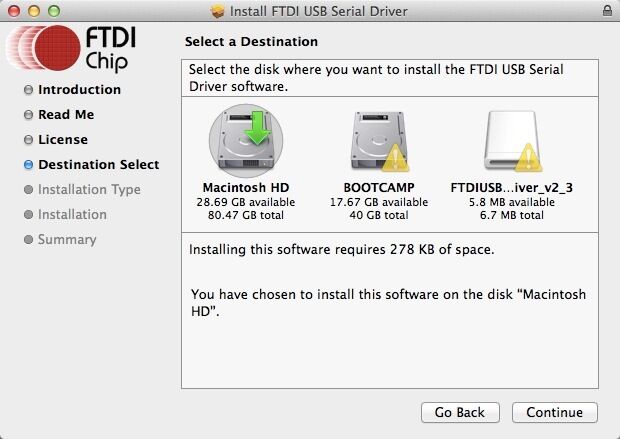

Select the installing destination and click "Continue".

Click "Install" in Installatin Type.

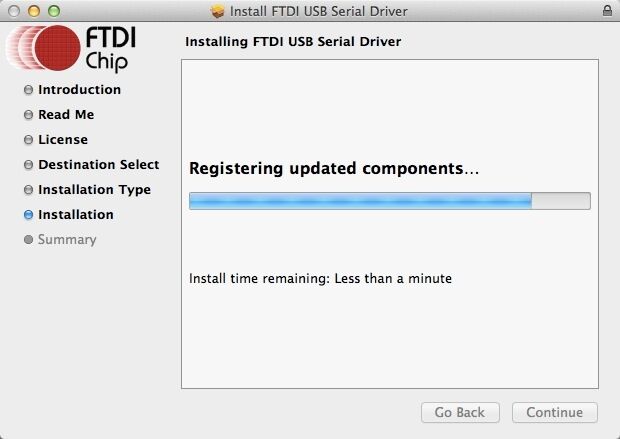

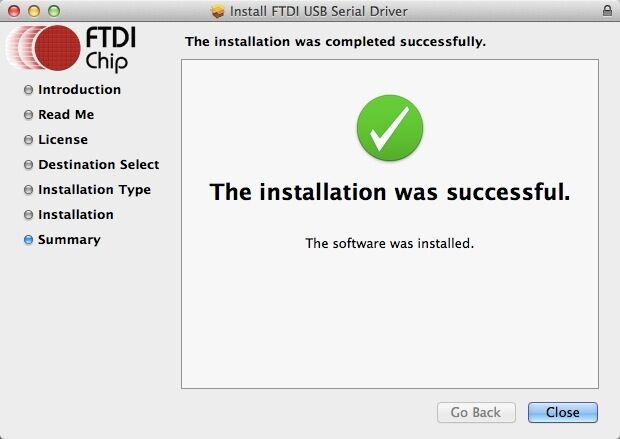

Mac will start to install the driver:

How to Install firmware

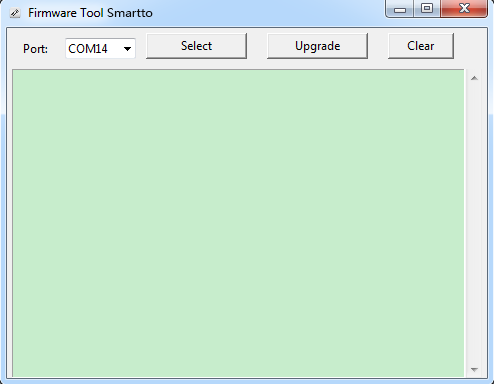

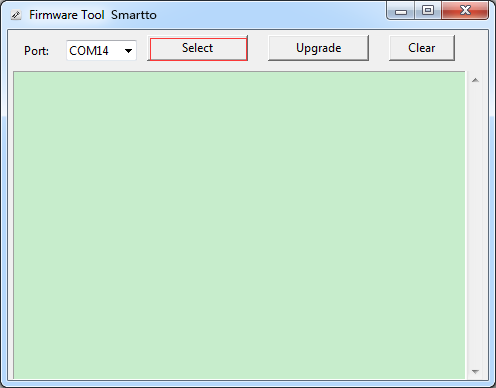

1. Download Firmware-download-tool and upzip the file.

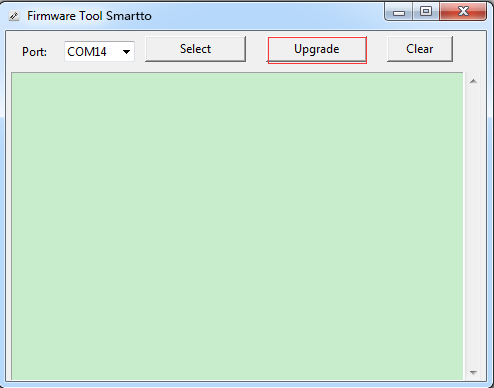

2. Connect your 3D printer with a computer. Double click “.exe” to start upgrading the firmware for GTM32 control board. A window will pop up, showing the COM port for your 3D printer.

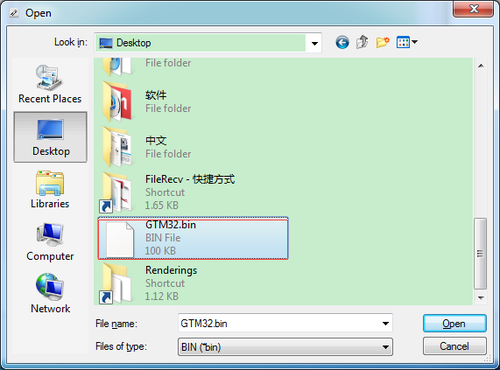

3. Click “Select” to choose the new firmware you’ve written, for instance, “GTM32.bin”.

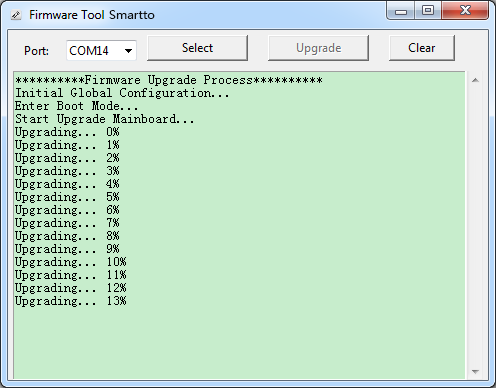

4. Click “Upgrade” and the upgrading will start automatically.

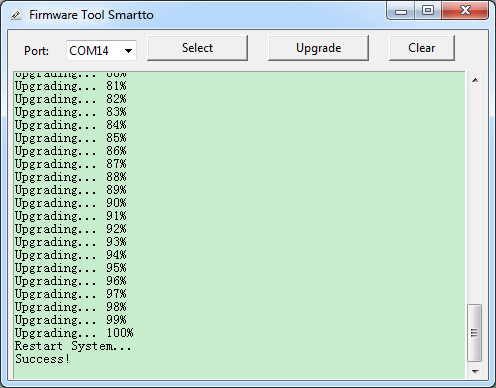

5. When the firmware is upgrade successfully, you will see the following window. Close the window to finish the whole process.

Open Source Firmware

Quick Start

GTM32 control board is self-developped by Geeetech, compatible with Reprap G.code instructions. It is based on ARM microprocessor STM32F103VET6 to control desktop 3D printer. This control board includes 4 stepper motor drivers: for X, Y, Z axis and extruder. The driver module on Z axis could connect 2 stepper motors, enabling dual rods on Z axis. The control board also supports 4 stepper motors, 1 extruder, 3 endstops, 1 heatbed and a 12V PSU (Please select a suitable PSU based on the power. We recommend 450W.)

Other expandable features for GTM32 control board are available including interfaces for Wi-Fi module (for remote controlling your 3D printer), filament detector (reminding you to change filament when the filament runs out or fractures), 3D touch, capacitive proximity sensor (for auto-leveling), and breaking-resuming module (resuming the unfinished print when the printer is powered on again.)

Software-related configuration:

You can modify the printing parameters on the basis of the source code. The baud rate of the GTM32 control board is 115200.

1. In the file “Configuration_Select_Printer.h”, you can select the printer types.

/*****************select printer********************/

//#define BOARD_A30_MINI_S 1 //A30 printer

//#define BOARD_A30S_Pro_S 1 //A30S printer

//#define BOARD_E180_MINI_S 1 //E180 Printer

- define BOARD_M301_Pro_S 1 //M301 Printer

2. File Configuration_XXXXXX.h covers the paremeters of your printer. You can adjust the parameters manually and flash the file into the control board. It is necessary to “restore factory settings” to make the file you’ve modified to work normally.

Eg. Settings for the max temp of heatbed and extruder

- define MAX_TEMPERATURE_BED 120.0 // Hot bed temperature max

- define MAX_TEMPERATURE_NO_1 250.0 //Extrusion head maximum temperature

Eg. Settings for the moving range of each axis

- define X_MAX_POSITION 320.0

- define Y_MAX_POSITION 320.0

- define Z_MAX_POSITION 420.0 //159.0

Eg. Settings for the position of endstops

- define HOMEX MINENDSTOP

- define HOMEY MINENDSTOP

- define HOMEZ MINENDSTOP

Eg. Settings for the rotating directions of stepper motors

- define DIR_X POSITIVE

- define DIR_Y POSITIVE

- define DIR_Z POSITIVE

- define DIR_E POSITIVE

- define DIR_E1 OPPOSITE

- define DIR_E2 POSITIVE

Eg. Settings for the micro steps of motors

- define STEPS_PER_mm_FOR_X 80

- define STEPS_PER_mm_FOR_Y 80

- define STEPS_PER_mm_FOR_Z 400.000

- define STEPS_PER_mm_FOR_E 85

You can use Repetier-host, Cura, Printrun etc. software to control your 3D printer. Please follow the specific operation steps for each software.

FAQ

a. How many extruders do GTM32 control board support?

A: One extruder at best.

b. What’s the output voltage for GTM32 control board?

A: 12V.

c. Are there other ways to adjust the program?

A: The control board provides SWD interface, which enables you to simulate debug the firmware via Keil, IAR, etc. software.

d. How can I flash the program via USB connectivity?

A: There is a jumper interface on the “Booto” of the control board. Connect the jumper and use Flash Loader Demo to flash it.

e. What are the features of GTM32 control board?

A: Supporting auto-leveling with 3DTouch and capacitive proximity sensor; compatible with WiFi module to remote control your 3D printer; featuring serial full-color touch screen; supporting two Z axis stepper motors connected in parallel.