Difference between revisions of "Building Instructions of Geeetech Prusa I3 M201"

(Created page with "500px Safety Instructions Building the printer will require a certain amount of physical dexterity, common sense and a thorough understanding of...") |

(→Assemble the front and back support of y axis.) |

||

| Line 92: | Line 92: | ||

Screw up the threaded rods and support plates with M10 nut and M10 washer at both end. Hand tighten the M10 Nuts against the M10 Washers. Try to keep the rods parallel and the four acrylic pieces parallel. | Screw up the threaded rods and support plates with M10 nut and M10 washer at both end. Hand tighten the M10 Nuts against the M10 Washers. Try to keep the rods parallel and the four acrylic pieces parallel. | ||

| − | [[File:2front and back support.jpg|500px]] | + | [[File:2front and back support .jpg|500px]] |

* Tips: | * Tips: | ||

Revision as of 08:57, 28 October 2015

Safety Instructions

Building the printer will require a certain amount of physical dexterity, common sense and a thorough understanding of what you are doing. We have provided this detailed instruction to help you assemble it easily. However ultimately we cannot be responsible for your health and safety whilst building or operating the printer, with that in mind be sure you are confident with what you are doing prior to commencing with building or buying. Read the entire manual to enable you to make an informed decision. Building and operating involves electricity, so all necessary precautions should be taken and adhered to, the printer runs on 12V supplied by a certified power supply, so you shouldn’t ever have to get involved with anything over 12V but bear in mind there can still be high currents involved and even at 12V they shouldn’t be taken lightly. High temperatures are involved with 3D Printing, the Extrusion nozzle of the hot end can run about 230°C, the heated bed runs 110°C and the molten plastic extruded will initially be at around 200°C, so special care and attention should be made when handling these parts of the printer during operation. We wouldn’t recommend leaving your printer running unattended, or at least until you are confident to do so. We cannot be held responsible for any loss, damage, threat, hurt or other negligent result from either building or using the printer.

Preparation

1. Unpack the kit and check if all parts are in the box and check the condition of each part, there might be some damage during shipping. To help you with this, there is BOM in the box and each bag was labeled with part number.

2. Contact our customer service immediately by email or through the website if you find any missing or damaged parts. And on the bottom of the BOM, there is a signature of reviewer, please take a picture of it and attach the picture in your mail.

3. Read through each chapter of these instructions to gain an over-all idea of what is involved and how long it might take, before starting on the work described. Or you can watch the video here.

4. Before you start, you can put all the part in order to save your time especially those screws and nuts. Do not mix them up.

5. Some printed parts may need more filing than others to ensure a secure fit when screwing together. Please do not over file a part, it is best to remove a small amount of excess plastic and test the fit then re-file as necessary. No excessive forces should be required to bring parts together.

6. Ensure you have the necessary skills to carry out the work, or enlist the help of someone who does.

7. Work on a big firm table or bench in a clean dry well-lit area.

8. This kit contains tiny parts; please keep them away from kids under 3.

9. Ask for help if you run into any problems - our contact details are on the website and we will always do our best to resolve any problems encountered.

Unfold the box and check the package list

Unfold the package and take all the parts out to check the condition of the items.

- All the acrylic plate has been etched with part ID and the plate is covered with a sheet of kraft paper, you need to tear them off.

- The part ID is corresponding to the number labeled on the bag of every part. Some parts may not have label, you can refer to the pictures on the package list.

=Assemble the threaded rods of Y axis=

| Required parts | Part ID | Required number |

|---|---|---|

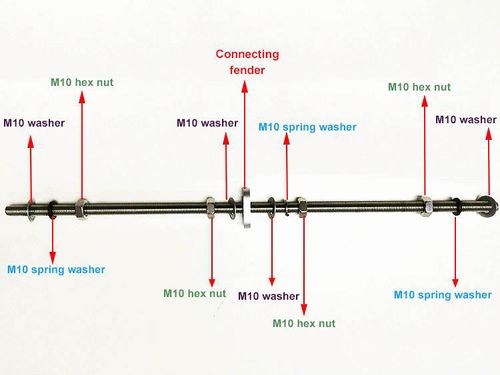

Thread the nuts and washers into the two M10 threaded rods separately. The order should be:

Watch the Video here.

Assemble the front and back support of y axis.

| Required parts | Part ID | Required number |

|---|---|---|

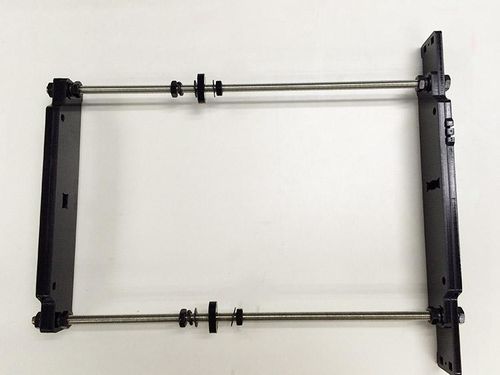

Thread the plate to both end of the threaded rod in the following order:2

Front outside support plate: No.A9

Front inside support plate: No.A10

Rear outside support plate: No.A12

Rear inside support plate: No.A11

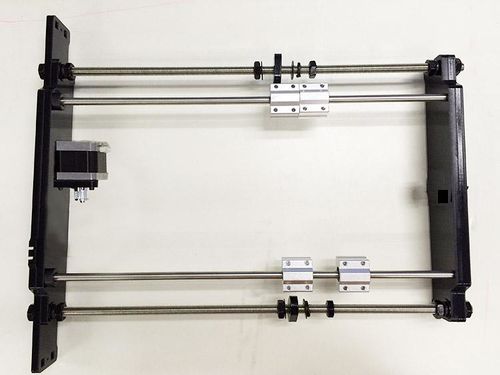

Screw up the threaded rods and support plates with M10 nut and M10 washer at both end. Hand tighten the M10 Nuts against the M10 Washers. Try to keep the rods parallel and the four acrylic pieces parallel.

- Tips:

the Y-axis must be a rectangle, that is the rods on both side should be parallel, so is the front and back plate. Otherwise it will cause obstruction for the belt later.

You can watch the video here.

Thread the smooth rods and linear bearings.

| Required parts | Part ID | Required number |

|---|---|---|

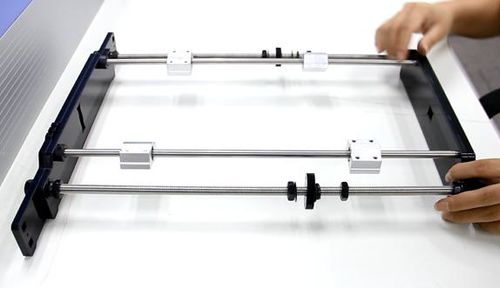

Thread the smooth rod into the Y axis support plate from rear to front, and thread the locking ring and 2 SCS8UU Linear Bearing on the smooth rod in turn.

Screw up the locking ring

Mount the Y motor

| Required parts | Part ID | Required number |

|---|---|---|

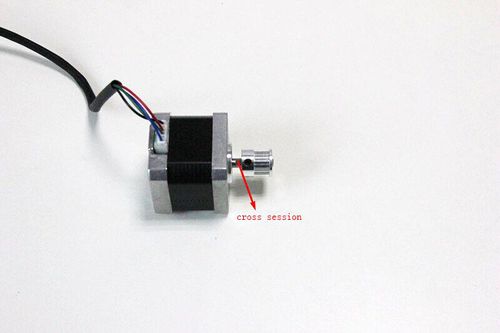

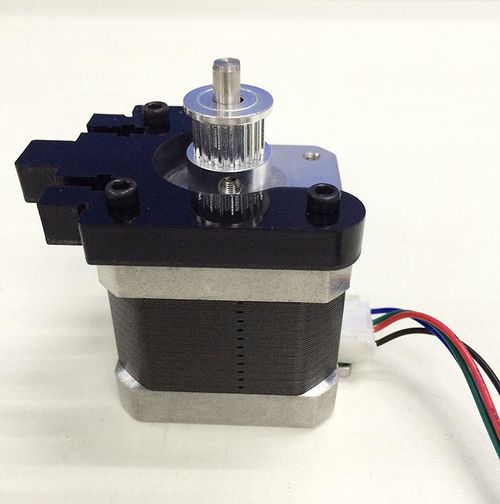

Step1. Mount the pulley on the motor shaft, one of the screws should be screwed on the cross section of the shaft. Screw it tightly.

Step2. Then screw the motor on the Y motor holder with 3 M3 x 12 screws and M3 washers.

Step 3. Push the Y Motor holder tab into the square hole in Rear -Outside Plate and Rear - Inside Plate. You may need to use a little force, but be careful not to break or crack any of the Acrylic pieces. Secure the Y Motor holder with 2 M3x16mm Screws , 2 M3 Washers and 2 M3 Square Nuts.

You can watch the video here.