Difference between revisions of "Geeetech Mizar Pro 3D Printer"

(→Unboxing and proper handling) |

(→Printer Maintenance) |

||

| Line 86: | Line 86: | ||

==Printer Maintenance== | ==Printer Maintenance== | ||

| + | |||

| + | === '''Turn the printer on but the screen does not work'''=== | ||

| + | |||

| + | |||

| + | === '''The printer is unstable'''=== | ||

| + | |||

| + | |||

| + | === '''Clean hotend'''=== | ||

| + | |||

| + | Preheat the nozzle to 220 Celsius from LCD menu. | ||

| + | |||

| + | Use a cleaner rod (1.5 mm diameter, 100 mm length) to push it in and out several times, making the clog out. Do not use excessive force. | ||

| + | |||

| + | [[File:M38.png]] | ||

| + | |||

| + | === '''Mintemp error'''=== | ||

| + | |||

| + | |||

| + | === '''The extruder keeps making a noise'''=== | ||

| + | |||

| + | |||

| + | === '''Nothing is printing'''=== | ||

| + | |||

| + | |||

| + | === '''Automatic leveling failed'''=== | ||

| + | |||

| + | |||

| + | === '''Spring steel sheet problem'''=== | ||

| + | |||

| + | |||

| + | === '''Filament sensor'''=== | ||

| + | |||

| + | |||

| + | === '''Firmware'''=== | ||

Revision as of 09:04, 9 May 2023

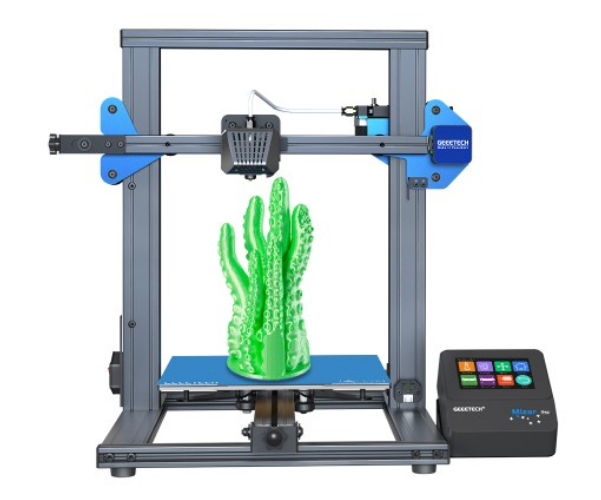

Introduction

Mizar Pro owns dual leveling technology, its printing accuracy is higher and the hot bed has been fixed, so don't worry about the hot bed being deformed or loosened. Its build volume is 220*220*260mm, and the appearance is more concise and beautiful, which can meet most of your printing needs!

Precise Auto leveling GEEETECH Mizar Pro has dual-leveling system, which enables one-button ABL automatic bed leveling technology. It is equipped with a high-precision leveling sensor and no need for external leveling accessories like BL touch.

It also creatively designed manual leveling mode, which is more friendly to beginners, amateurs and specialists.

Stable Magnetic Platform The heat bed adopts a fully fixed design, The hot bed can be used for a long time after leveling once with the leveling sensor, do not need frequently leveling the hot bed;The hot bed printing platform adopts the magnetic suction method. Compared with the ordinary magnetic printing platform, the top component of the Mizar Pro printing platform is made of metal material, it is durable and easy to remove the model.

Super Silent Driver The Mizar Pro motherboard uses a high-performance 32-bit MCU with faster printing speed. TMC2208 silent driver can effectively reduce the noise of stepper motor than Atmega2560, the printing sound doesn't exceed 50 dBs, which will not disturb your and others work, study and rest.

Resume Printing Function This 3d printing machine can detect interruptions of power failure, filament run out or stuck, it will automatically pause and save the printing progress, when you handle the exception, it'll resume the previous printing task, which gives your printing work an extra layer of protection.

Product details

Main Specification

Printer Type FDM

Layer Thickness 0.1-0.3 mm

Printing Material PLA,ABS, PETG, Silk PLA, Wood Polymer

Building Platform Volume 220*220*260 mm

Auto-leveling Yes

Break Resuming Yes

Preheat time(110℃) 11 min

Nozzle Diameter 0.4 mm

Positioning Precision X axis: 0.011 mm;Y axis: 0.011 mm;Z axis: 0.0025 mm;

Printing Accuracy ±0.1 mm

Printing Speed 10~150 mm/S; recommend 60~80 mm/s

Display Screen 3.5” Colorful Touch Screen

Operating System Windows, Mac, Linux,

Slicing Software Repetier-Host, EasyPrint Lite, Cura

Supported File Format .gcode

Hotbed Max. Temperature 110 ℃

Extruder Max. Temperature 250 ℃

Environmental Temperature 10-40 ℃

Electrical Parameter

Power Input 115/230 V AC, 50/60 Hz

Power Output DC 24 V-15 A Max, 360 W

Connectivity Interface 1*TF Card, 1*USB cable

Power Supply Unit Certification CE, FCC,ROSH

Mechanical Parameter

Printing Size 220*220*260 mm

Net Weight(kg) 8.9 kg

Gross Weight(kg) 9.6 kg

Printer Whole Size 462(W)*515(L)*445(H) mm

Packing Dimension 512(L)*512(W)*274(H) mm

Unboxing and proper handling

Watch the unboxing video and user manual before assembling the printer.

Printer Maintenance

Turn the printer on but the screen does not work

The printer is unstable

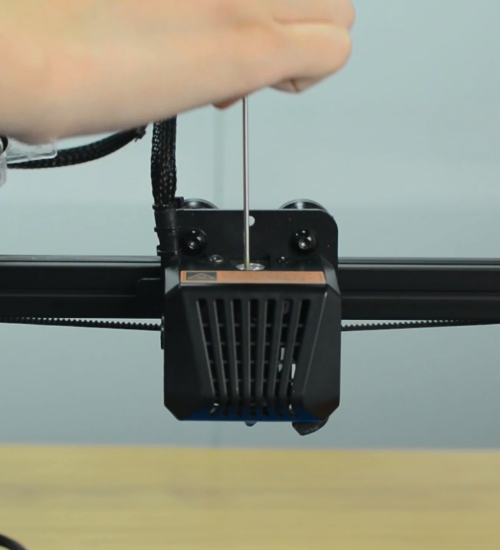

Clean hotend

Preheat the nozzle to 220 Celsius from LCD menu.

Use a cleaner rod (1.5 mm diameter, 100 mm length) to push it in and out several times, making the clog out. Do not use excessive force.