Difference between revisions of "Acrylic Prusa I3 build instruction(8mm)"

(→Build the printing platform) |

(→Assemble Y - Z axis) |

||

| Line 218: | Line 218: | ||

=Assemble Y - Z axis= | =Assemble Y - Z axis= | ||

| − | |||

{|class="wikitable" | {|class="wikitable" | ||

|- | |- | ||

| Line 231: | Line 230: | ||

|<center>M3 nut</center>||<center>4</center>||<center>NO.11</center> | |<center>M3 nut</center>||<center>4</center>||<center>NO.11</center> | ||

|} | |} | ||

| + | |||

| + | Step1. Held upright the main frame is after the acrylic fender washers on the threaded rods. Here you can use the A2 panel as a reference to measure the distance A1 and A12 (the rear plate). | ||

[[File:Acrylic Prusa I3 (8mm)pic22.jpg|500px]] | [[File:Acrylic Prusa I3 (8mm)pic22.jpg|500px]] | ||

| + | |||

| + | Step2. Screw up the main frame to the acrylic fender with M3 x 20 screws. | ||

| + | |||

| + | Step3. Screw up the M10 screw on the threaded rod of Y-axis. You can see the finished picture. | ||

=Mount the fan= | =Mount the fan= | ||

Revision as of 05:47, 2 April 2015

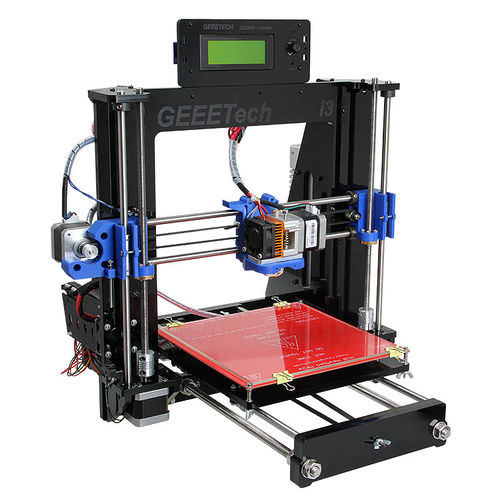

Notice:

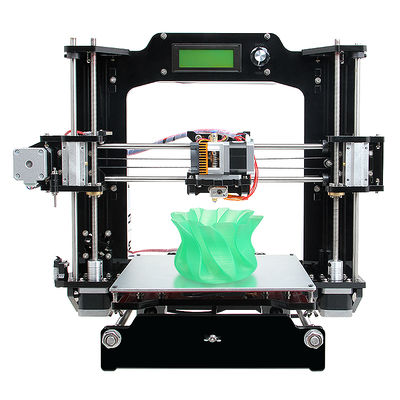

1. This kit contains tiny parts; please keep them away from kids under 3.

2. This building instruction applies to both Geeetech Acrylic Prusa I3 pro and pro B.

3. Some pictures of the printed part may be a bit different from those in your package, no worries, they work the same, and the way to assemble is similar.

4. Building and operating 3D printer involves electricity, so all necessary precautions should be taken and adhered to.

5. Building a 3d printer requires a certain amount of handling ability and basic knowledge of working principle of 3D printer.

6. Be patient, please. If you have any problems assembling, please contact us, we will try our best to help you.

Contents

- 1 Unfold and check the package

- 2 Assemble Y axis (the bottom part of the chassis)

- 3 Assemble Y - Z axis

- 4 Mount the fan

- 5 Assemble the right and left side panel

- 6 Assemble the Z axis (the vertical axis)

- 7 Assemble the X axis (the horizontal axis)

- 8 Mount the extruder on the X axis

- 9 Assemble the X-Z axis

- 10 Mount the end stops

- 11 Mount the LCD panel frame

- 12 Mount the filament spool

- 13 Mount the PSU

- 14 Mount the control board on the left side panel

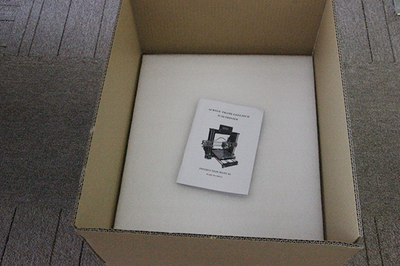

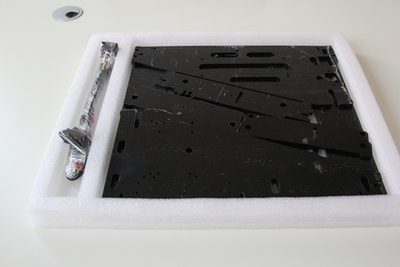

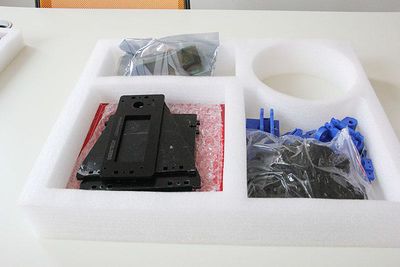

Unfold and check the package

Unfold the package and take all the parts out to check the condition of the items. As you can see, all the parts are packed very carefully.

·All the acrylic plate has been etched with part ID and the plate is covered with a sheet of kraft paper, you need to tear them off. .

Tips:

- Before assembly, you are advised to put all the parts, especially the screws and nuts in order, which will save you a lot of time looking for the required parts.

- The part ID is corresponding to the number labeled on the bag of every part.

Assemble Y axis (the bottom part of the chassis)

Assemble the rods of a Y axis

Step1. Assemble the 2 threaded rods.

| Required parts | Required number | Part ID |

|---|---|---|

Thread the nuts and washers into the two M10 threaded rods separately. The order should be:

1) Thread the acrylic fender (Y plate connecting plate) in the middle.

2) Thread the M10 washer > M8 spring washer >M10 nut > M10 nut > M10 washer on the left

3) Thread theM10 washer < M8 spring washer < M10 nut < M10 nut< M8 spring washer < M10 washer on the right

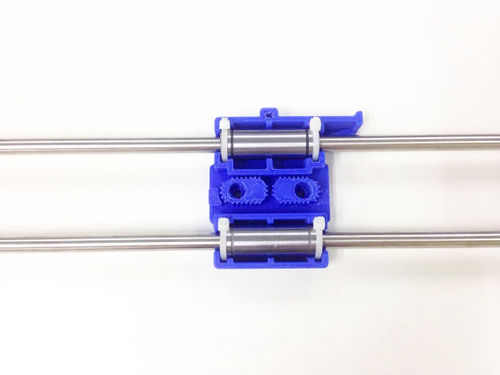

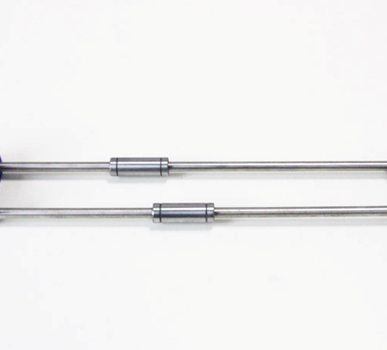

Step2. Assemble the 2 smooth rods

| Required parts | Required number | Part ID |

|---|---|---|

Slide 2 bearings on each smooth rod. Before you slide the bearings please make sure they are clean.

Attach the front and rear Acrylic support plates of the rods

| Required parts | Required number | Part ID |

|---|---|---|

Step1. Slide the rods into the acrylic plate; adjust the length so that the smooth rods fit snugly between the front and rear piece.

Step2. Screw up the rods and plate with M10 nut and M10 washer.

Tips: the Y-axis must be a rectangle, that is the rods on both side should be parallel, so is the front and back plate. Otherwise it will cause obstruction for the belt later. You can use a Digital Caliper to measure. .

Assemble the Y idler

| Required parts | Required number | Part ID |

|---|---|---|

Step1. Thread the M3 x 20 screw through thethe bearing holder.

Step2. Put the M4 x25 screw through the holes with the two 624ZZ bearings in between. Lock the other end with a M4 lock nut.

Step3. Mount the assembled bearing holder onto the front support plates. And screw it with a wing nut.

*Please leave enough room for the belt between the ball bearing and the screw.

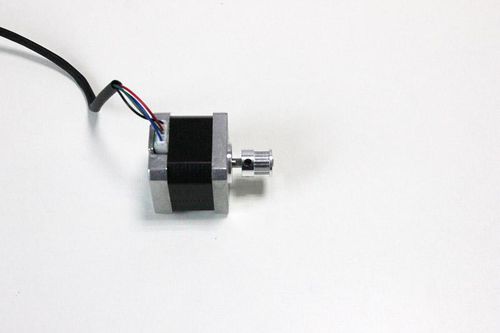

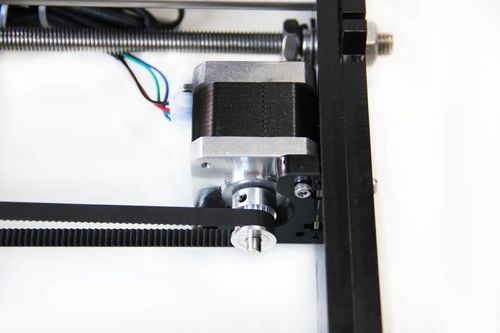

Mount the Y motor

| Required parts | Required number | Part ID |

|---|---|---|

Step1. Mount the pulley on the motor shaft, one of the screws should be screwed on the cross section of the shaft. Do not screw too tight to turn smoothly.

Step2. Insert the motor block into the slot; you may need to use a little strength to do this. But be careful in case the Acrylic broke down. Then screw the motor on the block plate with 3 M3 x 12 screws and fix the block plate with 2 M3 x 16 screws and M3 square nut.

Build the printing platform

| Required parts | Required number | Part ID |

|---|---|---|

Step1. Mount the belt mount on the bottom side of the platform with 2 M3 x 10 screws.

Step2. Mount the 4 Acrylic fenders on the platform with M3 x 20 screws and M3 nuts on the same side with the belt-mount. Screw with M3 nuts.

Step3. Get the build platform plate zip-tied to the 4 linear bearings of Y- Axis.

*The belt-mount and the fenders are under the platform.

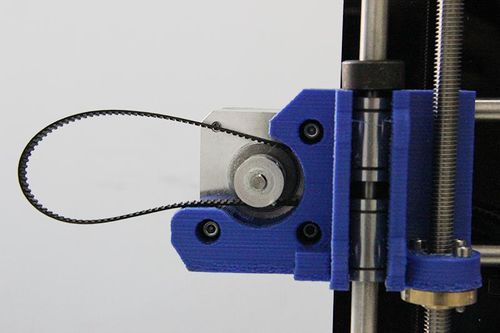

Step4. Mount the belt.

| Required parts | Required number | Part ID |

|---|---|---|

Step1. Drill a hole on one end of the belt(the hole can be as the diameter of the M3 screw, leave enough margin )

Step2. Fix the belt on one side of the belt -mount with a M3 x 10 screw and washer.

Step3. Thread the belt around the pulley on the motor and the Y idler.

Step4. Drill a hole on the other end of the belt and fix it on the belt -mount with a M3 x 10 screw and M3 washer.

- Tips: before you mount the other end, you should straighten the belt tightly, if it is too loose, it will hinder the move of the print platform.

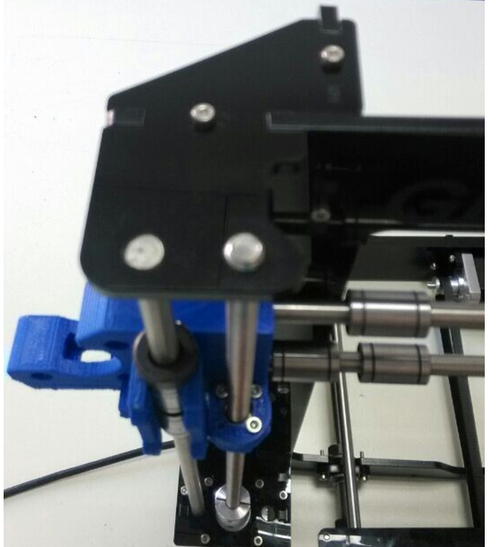

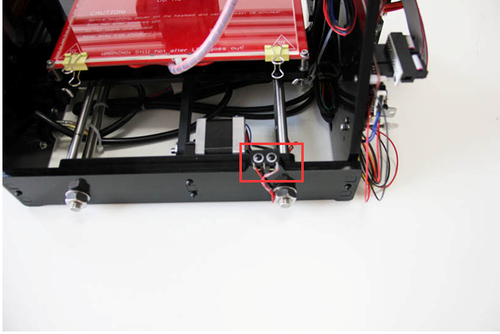

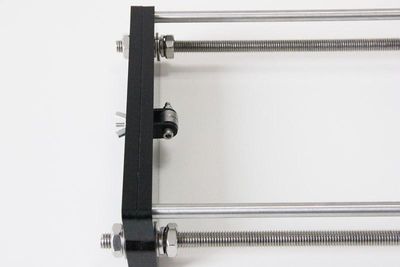

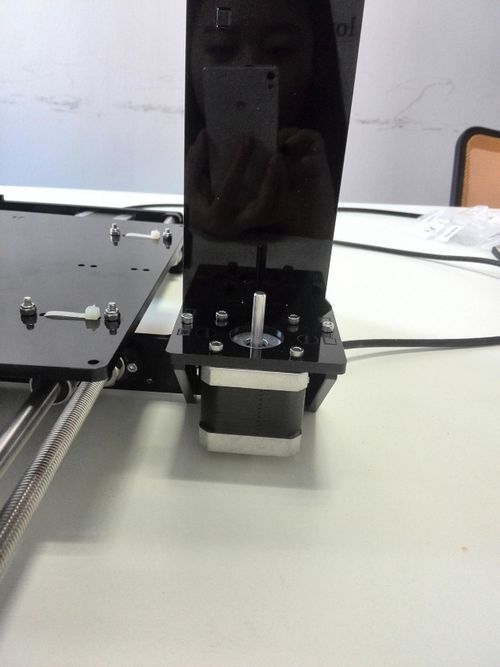

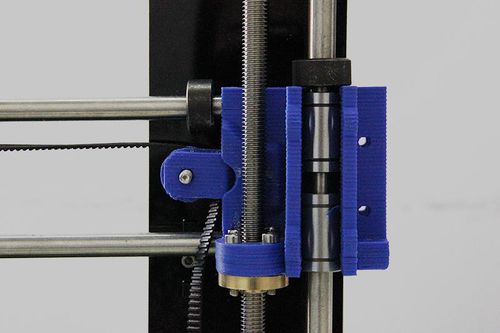

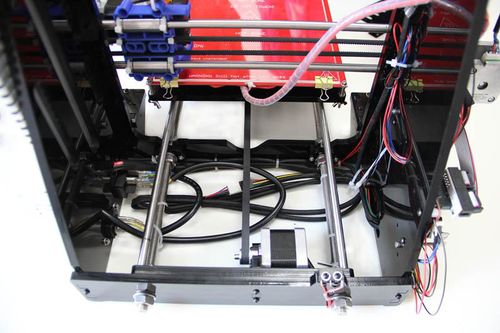

Assemble Y - Z axis

| Required parts | Required number | Part ID |

|---|---|---|

Step1. Held upright the main frame is after the acrylic fender washers on the threaded rods. Here you can use the A2 panel as a reference to measure the distance A1 and A12 (the rear plate).

Step2. Screw up the main frame to the acrylic fender with M3 x 20 screws.

Step3. Screw up the M10 screw on the threaded rod of Y-axis. You can see the finished picture.

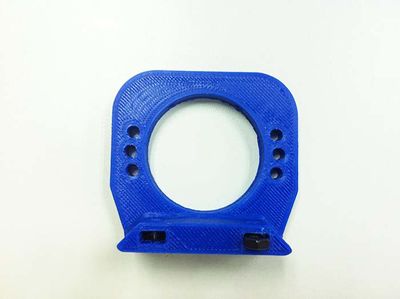

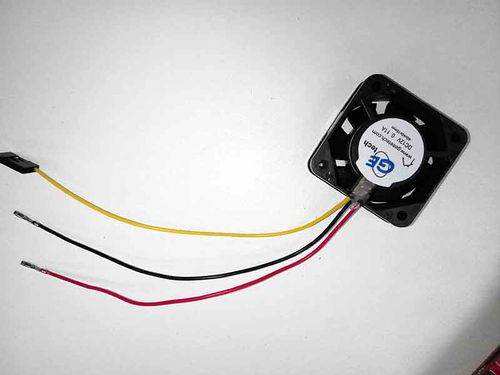

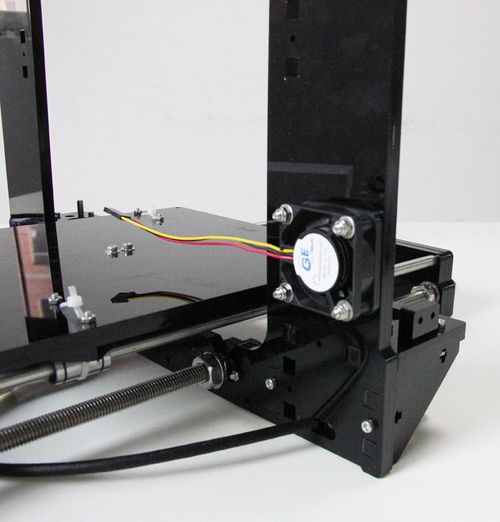

Mount the fan

| Required parts | Required number | Part ID |

|---|---|---|

Fix the fan on the right side of the frame with 4 M3 x 30 screw and lock nut. Mind the direction of the wires.

Assemble the right and left side panel

| Required parts | Required number | Part ID |

|---|---|---|

Screw up the X-Z frame and the side panel then connect the rear part of the Y axis and the side panel together. You may need to adjust the distance of the X-Z frame to the rear plate.

Assemble the Z axis (the vertical axis)

Assemble the Z-axis bottom mount

| Required parts | Required number | Part ID |

|---|---|---|

Screw up the acrylic plates with M3 x 16 screws and M3 square nuts.

*The right and left bottom mount are different; the left one has a mount for the Z end stop. Please look at the following picture.

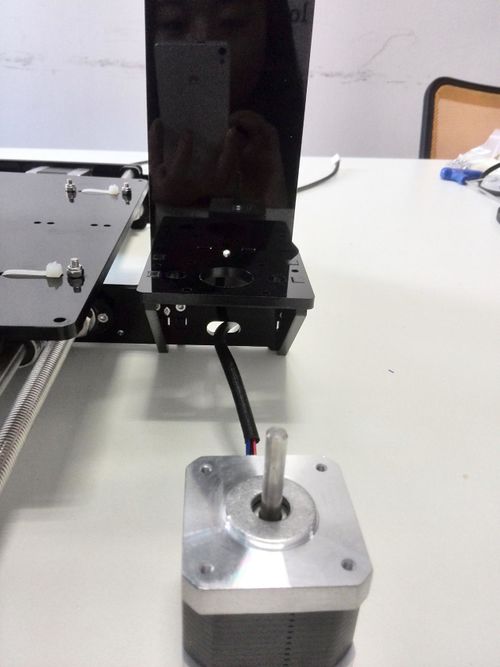

Assemble the 2 Z motors

| Required parts | Required number | Part ID |

|---|---|---|

Step1.Thread the wires of the motors through the holes

Step2. Screw up the motors with M3 x 12 screws.

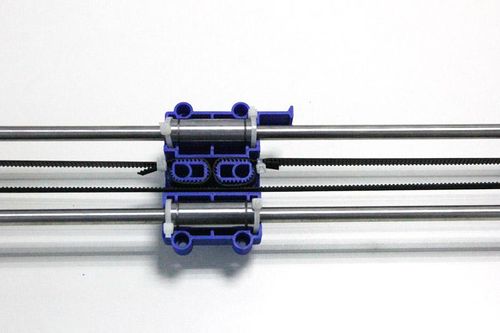

Assemble the X axis (the horizontal axis)

Assemble the X-Axis Idler

| Required parts | Required number | Part ID |

|---|---|---|

Put the screw through the printed Y idler piece, with the 624ZZ bearings in between. Lock the other end of a M3 nut.

Mount the assembled idler into the X-axis end. Lock it up with a wing nut. Here, you can insert the linear bearing into the end.

Insert a linear bearing into the other end of X-axis.

Assemble the X-axis smooth rod and the X-axis ends

| Required parts | Required number | Part ID |

|---|---|---|

Slide the two bearings into the two rods respectively. Then thread the two locking fender into the right end of both rods.

Thread the two rods into the two X-axis ends and then mount the brass nut under both ends.

Mount the extruder on the X axis

Thread the zip-tie through the extruder bracket

| Required parts | Required number | Part ID |

|---|---|---|

Step1. Mount the X-axis belt bracket on the smooth rods. As you can see from the picture, the two linear bearings should be placed into the two slot of the bracket. Tie them up with zip ties.

Mount the extruder support

| Required parts | Required number | Part ID |

|---|---|---|

1.Put the 2 M4 nut into the hole, as shown in the picture.

2. Screw up the belt bracket and the extruder support with two M4 x 16screws.

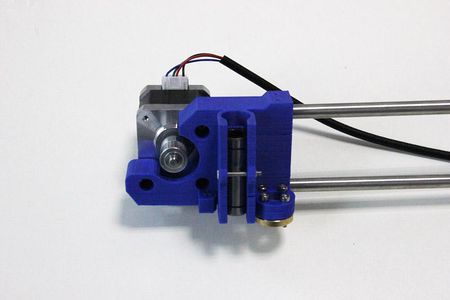

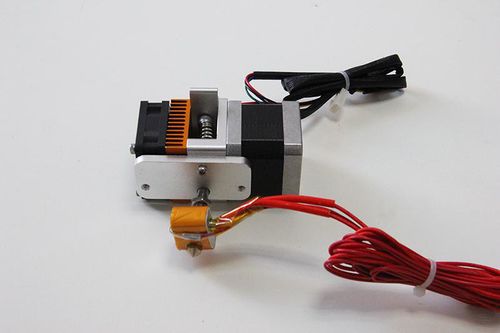

Mount the extruder

| Required parts | Required number | Part ID |

|---|---|---|

This is the fully assembled MK8 extruder in the package.

Take the nozzle part and the bolt out.

Mount the aluminum plate under the extruder.

Then mount the assembled extruder on the extruder support. Use 2 M4 x 12 screws to fix. (the blue extruder support)

Mount the X-axis motor

| Required parts | Required number | Part ID |

|---|---|---|

Mount the pulley on the motor shaft, one of the screws should be screwed on the cross section of the shaft. Do not screw too tight to turn smoothly

mount the motor on the X-axis motor holder, screw it up with 3 M3 x8 screws.

Amount the X-axis belt

| Required parts | Required number | Part ID |

|---|---|---|

Thread the belt through the motor end. The belt is attached on the pulley.

Another end of the belt should be threaded through the belt holder on the right end of the X-axis.

*Pay attention to the tooth mesh of the belt and that on the bracket. Tie up both ends tightly.

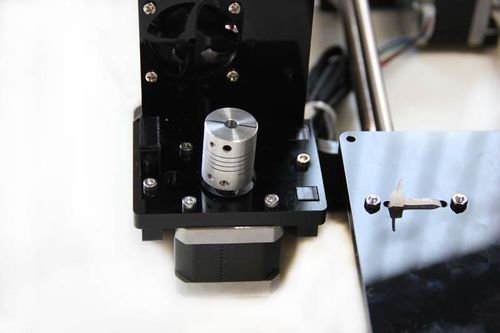

Assemble the X-Z axis

Step1. Thread the threaded rod of Z axis through the following part. It would be easier to do it now.

| Required parts | Required number | Part ID |

|---|---|---|

Step2. Fix the two couplings on both of the threaded rod. And plug it on the motor shaft.

| Required parts | Required number | Part ID |

|---|---|---|

*Mind the opening of the couplings, the larger opening should be put into the threaded rod.

Step3. Put the assembled X-axis on the Z-axis. Then slide the smooth rod into the linear bearings.

Step4. Assemble the top mount of the Z-axis.

| Required parts | Required number | Part ID |

|---|---|---|

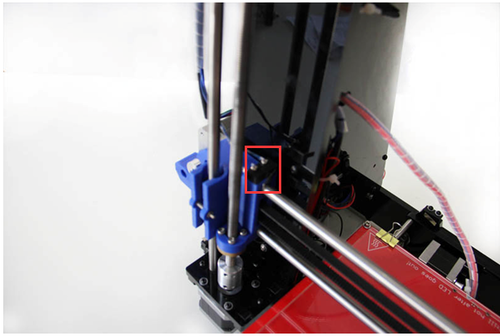

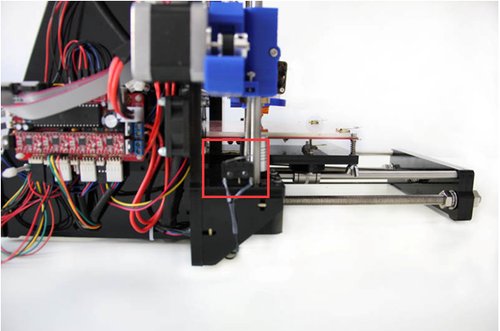

Mount the end stops

Step 1.End stop of X-axis

| Required parts | Required number | Part ID |

|---|---|---|

Step2. End stop of Y-axis

| Required parts | Required number | Part ID |

|---|---|---|

Step3. End stop of Z-axis

| Required parts | Required number | Part ID |

|---|---|---|

Mount the LCD panel frame

| Required parts | Required number | Part ID |

|---|---|---|

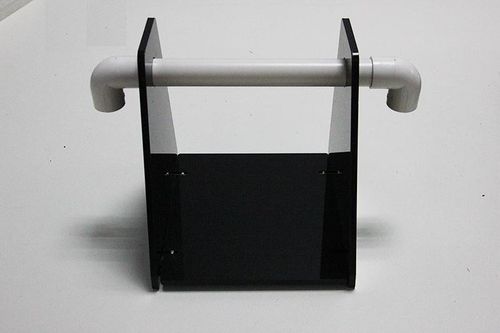

Mount the filament spool

| Required parts | Required number | Part ID |

|---|---|---|

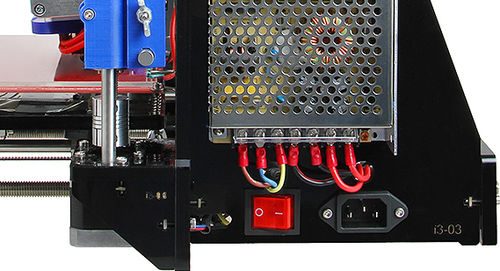

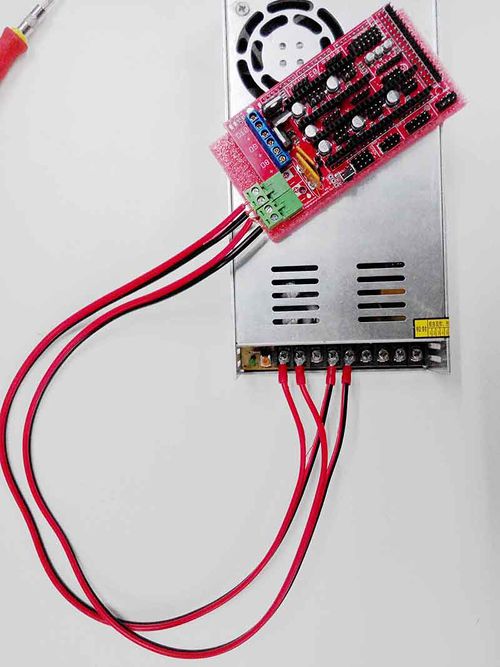

Mount the PSU

| Required parts | Required number | Part ID |

|---|---|---|

Mount the PSU on the right side panel with 3 M3 x 10 screws.

Then mount the AC socket with M3 x 20 screws.

You have to take off one end of the connectors to get both the power button and the power socket into the hole.

1. Mind the color of the wires. The wrong connection of the wire will cause serious damage to the PSU and even to the control board of the printer.

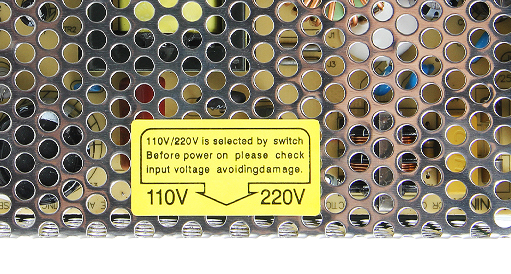

2. Pay attention to the switch on the right side of the PSU, there are two options of voltage: 110 V and 220V, choose according the standard in your country. As shown in the following picture.

After connection, please close the protective cover to avoid electronic shock.

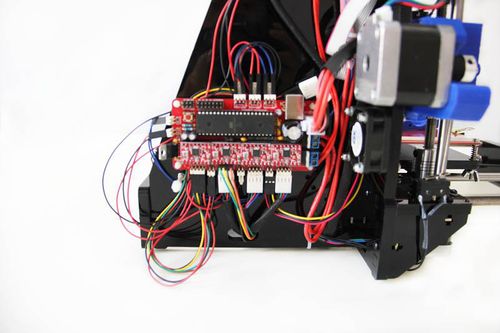

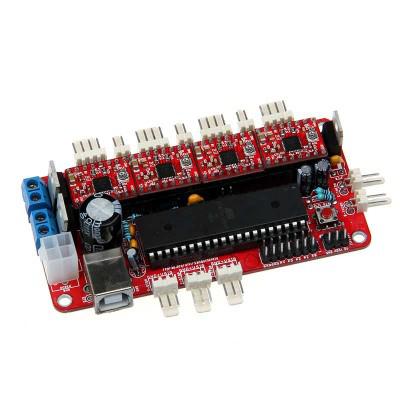

Mount the control board on the left side panel

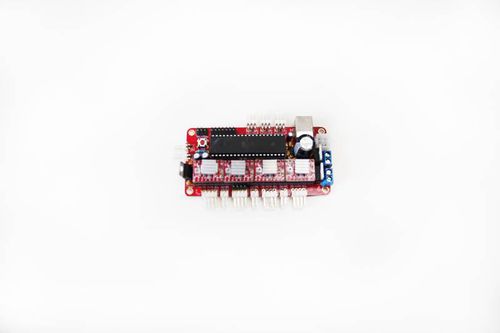

Example 1: Sanguinololu

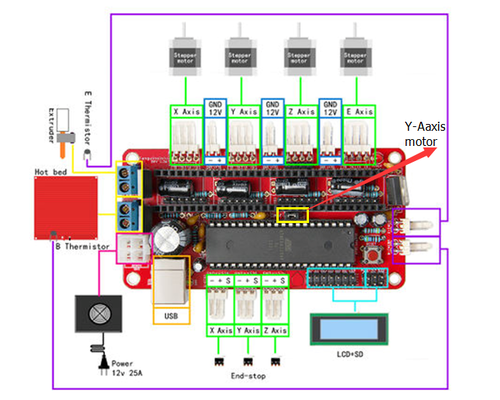

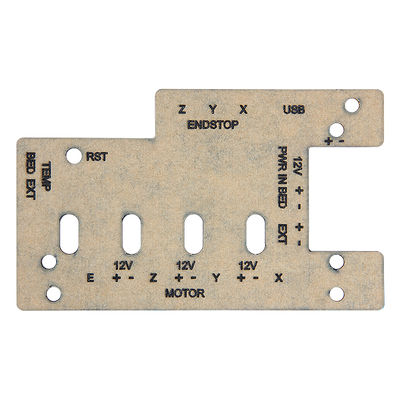

Here we take the Sanguinololu as an example.

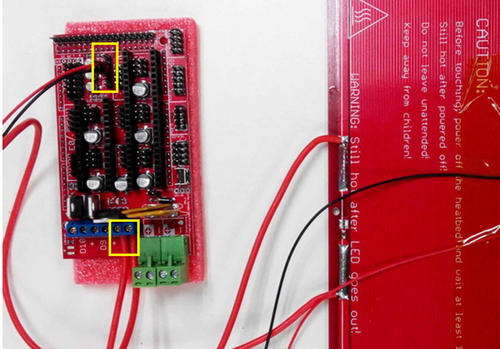

Step1, plug the jumper caps on the following pins of the board. (In the yellow circle)

* These caps are very tiny; do not throw them away inadvertently.

The jumper caps are packaged along with the board, do not lost them.

You need to plug 12 caps in all.

Step2. Stack the 4 A4988 on Sanguinololu

Step3. Stick the heat sink on the chip of the 4 A4988.

Step4, connect all the wires to the interfaces of the board

The referring wiring schematic diagram of Sanguinololu

* use the Dopont cable in the package to strech the wire of fan for extruder, you just need to connect the black and red one, leave the yellow one alone.

also you can refer to the board cover.

For more information about Sanguinololu, please visit the wiki page.

Note: when connect the other Y-motor, use the 4-pin M-F DuPont cable and pay attention to the directions of the wire. If you connect them reversely, the 2 Z motor will move in different directions.

Look at the colors of the wire.

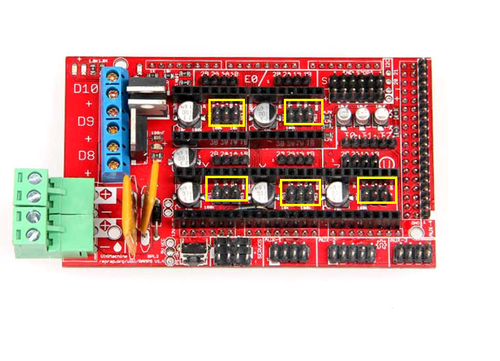

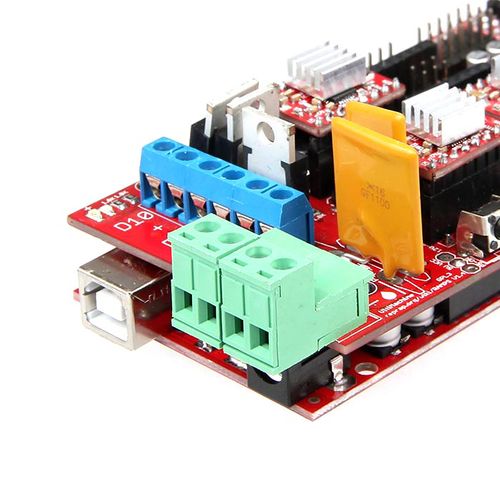

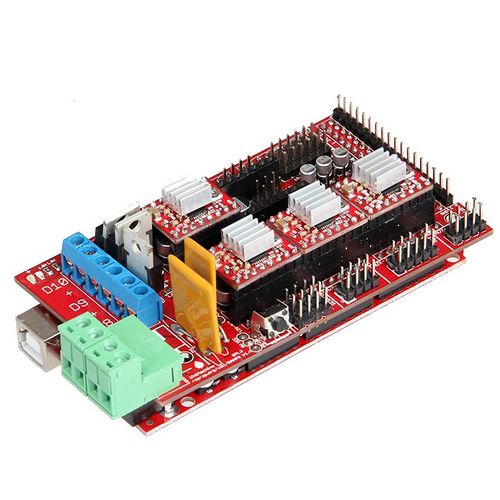

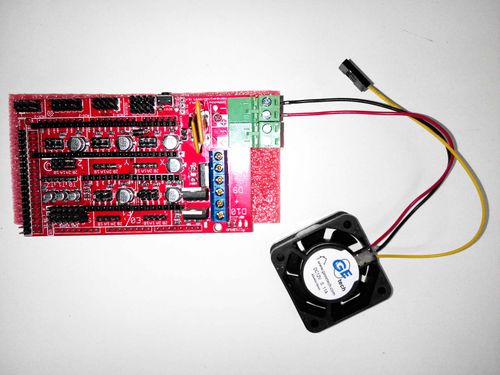

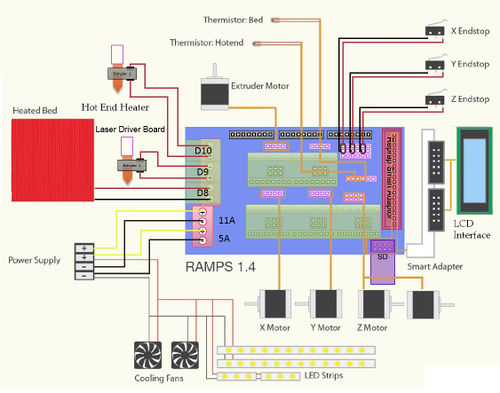

Example 2: Ramps 1.4

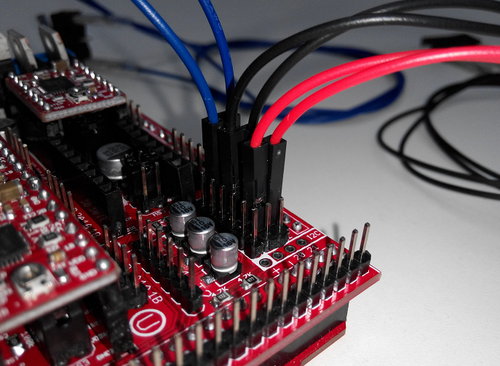

Step1.Plug the jumper caps on ramps 1.4. You need 15 jumper caps in total.

Step2.Stack ramps 1.4 onto mega 2560.

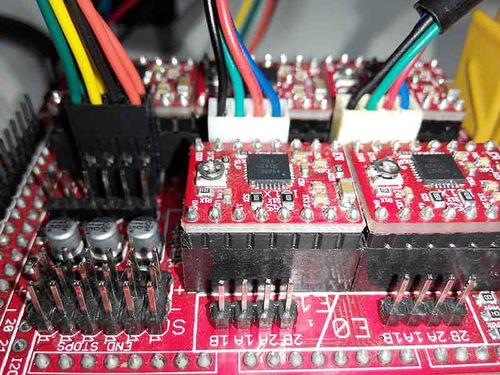

Plug the 4 A4988 motor driver boards on ramps1.4; stick the heat sinks on the driver boards.

(one for X, one for Y, one for extruder, two for Z)

Mind the directions of the driver boards. You can see the “GND” on the board.

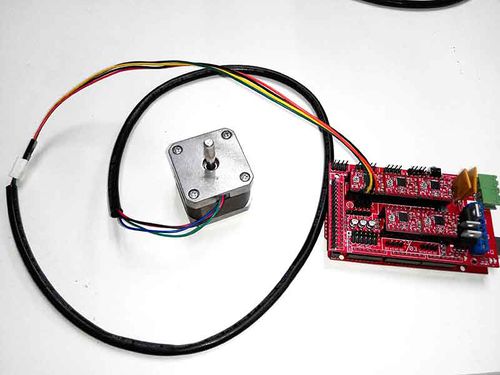

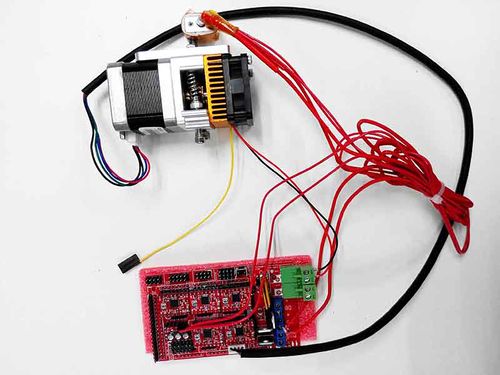

Wiring

The referring wiring schematic diagram of Ramps 1.4

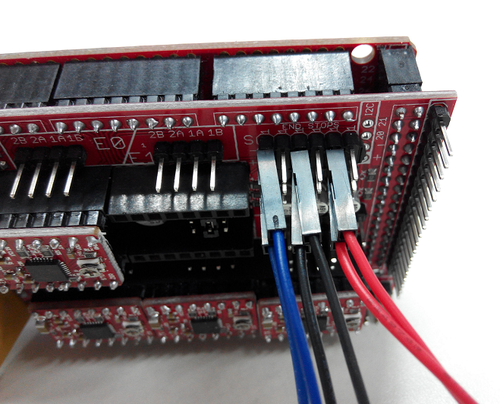

1.Connect motors. X and Y motors are easier, here you need to notice the Z motor, you need two 4-pin DuPont cable to extend for 2 Z motors.

2.Connect the fan; both the fan for extruder and the main board are connected like this. As to the fan for extruder, you need another 2-pin DuPont cable to extend. Take off the adapters and plug the cable into the power port.

3.Connect the heatbed.

4.Connect the extruder

The 2-pin DuPont cable with adapter is for thermometry, the thicker one is for heating.

5.Connect the end stops.

- Connect the wires to "S" and "-" pins.

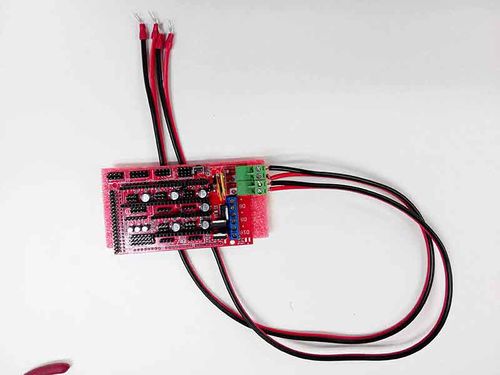

6.Connect the power supply.

First you should take off the white adapter.

Then screw the cable into the power port. Notice the “+” and “-“ Red is “+”. Black is “-“.

Plug the other end into the PSU.

For more information about ramps 1.4, please visit the ramps 1.4 wiki.

Step5. Mount the board on the left side panel of the printer. And cover the board with the acrylic plate.

| Required parts | Required number | Part ID |

|---|---|---|

Note that, when mount the board, please put the power port towards the cooling fan, or there may be some damaged caused to the board. This is very important, especially for Rampms 1.4.

All the wires can be tied together under the printer, but you should make sure they don’t touch the belt.

Arrange the wires and tidy up them with the coil.

The whole printer assembly work is already done.

Hope you enjoy the whole process.