Difference between revisions of "Mizar M"

(→Simplify 3D) |

(→Separate Color Printing) |

||

| Line 395: | Line 395: | ||

[https://www.geeetech.com/download.html?version_id=531 Mizar M Simplify 3D Configuration] | [https://www.geeetech.com/download.html?version_id=531 Mizar M Simplify 3D Configuration] | ||

| + | |||

| + | |||

==== Separate Color Printing ==== | ==== Separate Color Printing ==== | ||

| + | Applied to both Gradient Color module and Separate Color module. | ||

| + | |||

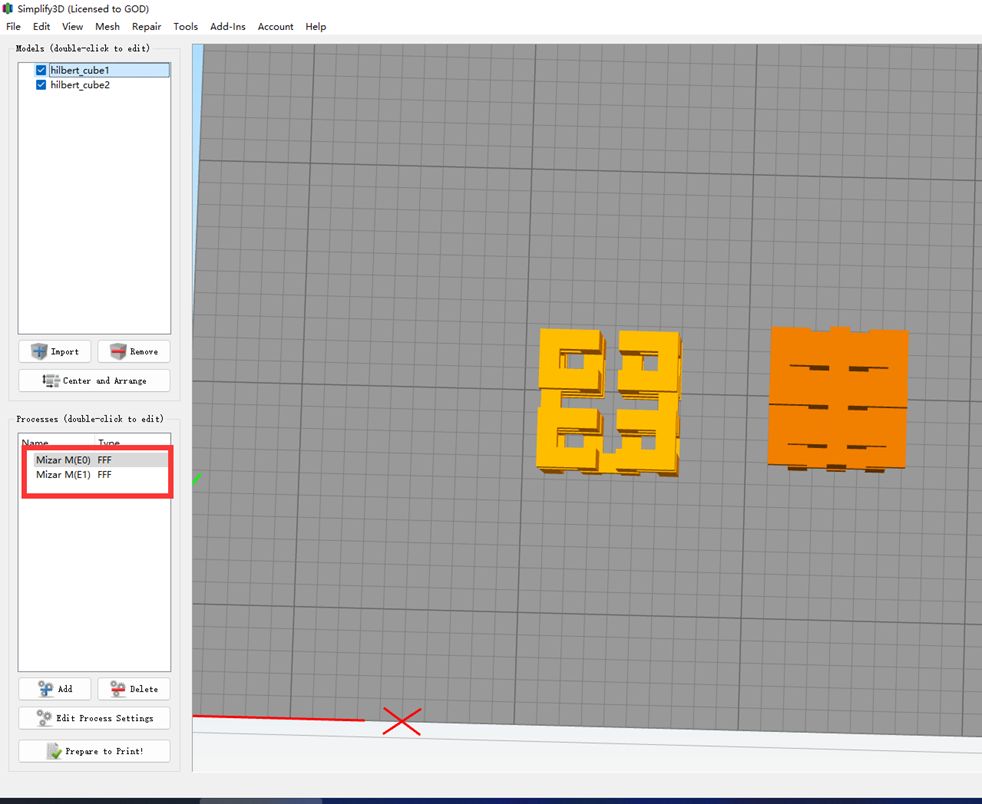

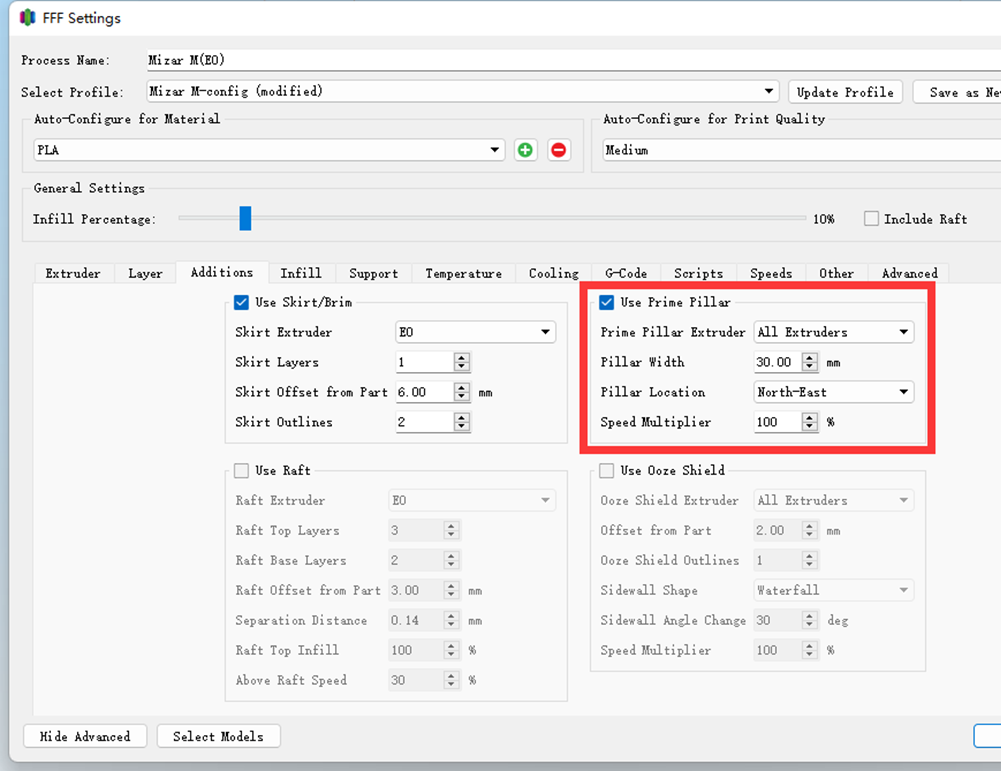

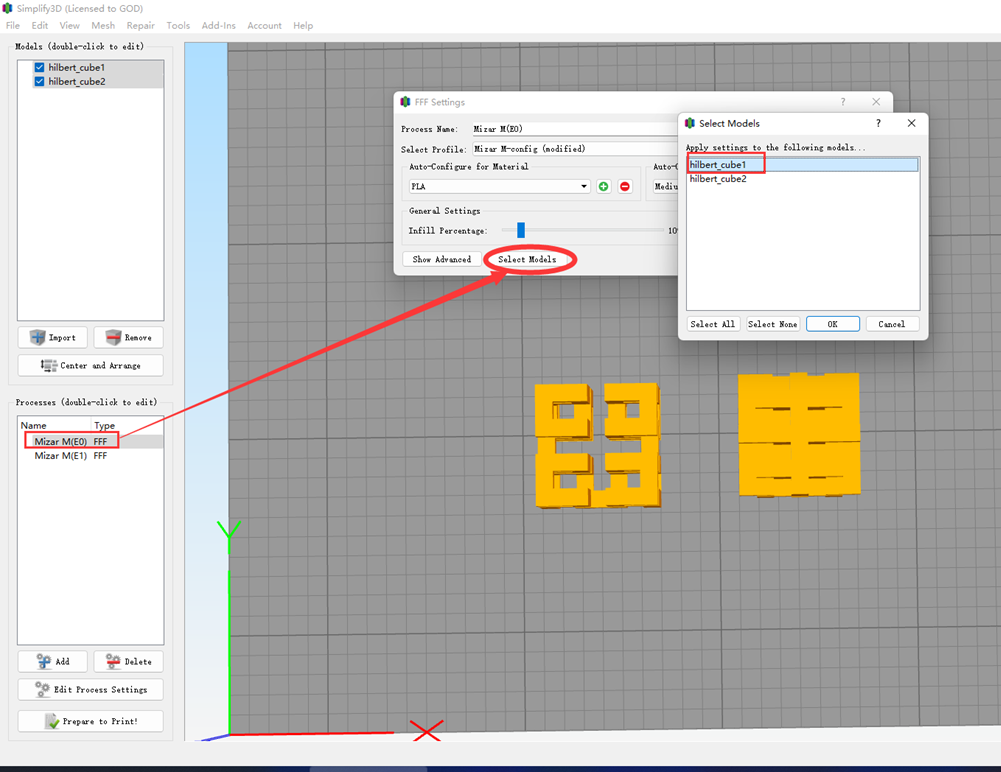

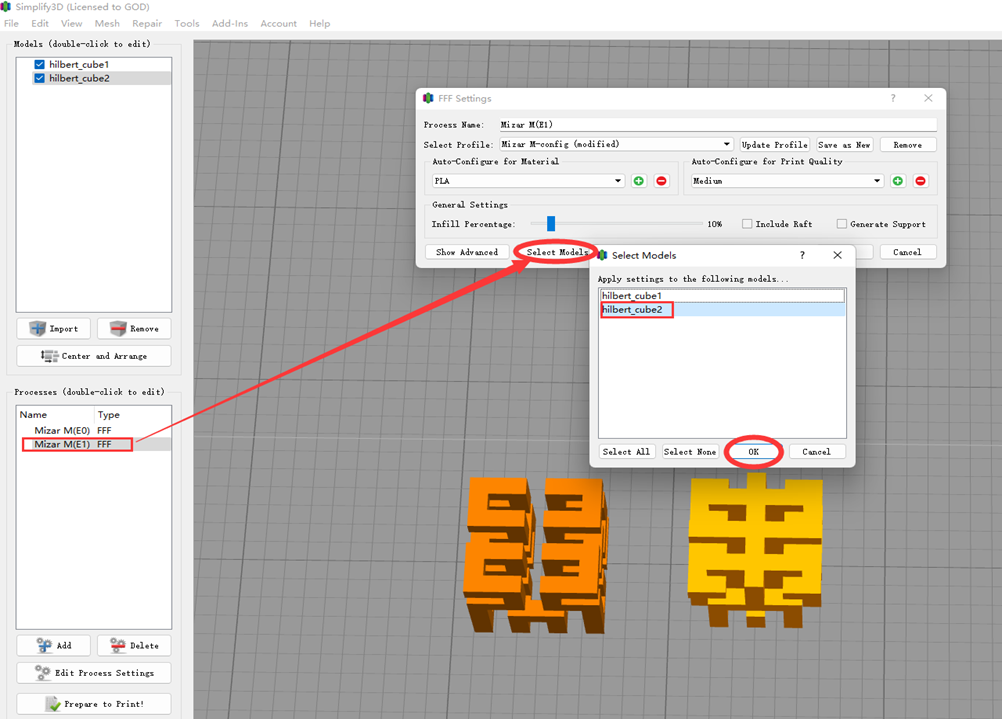

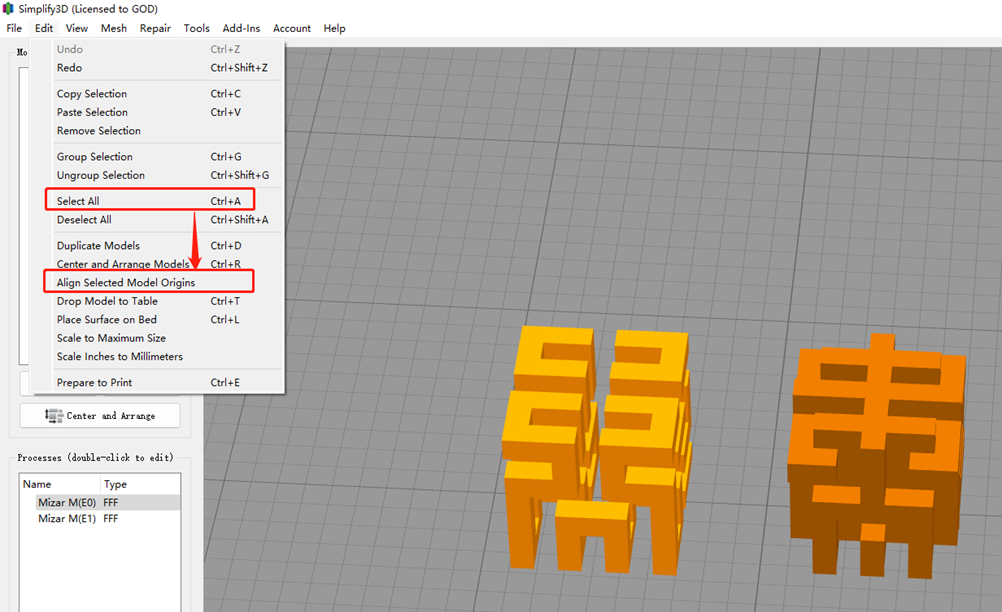

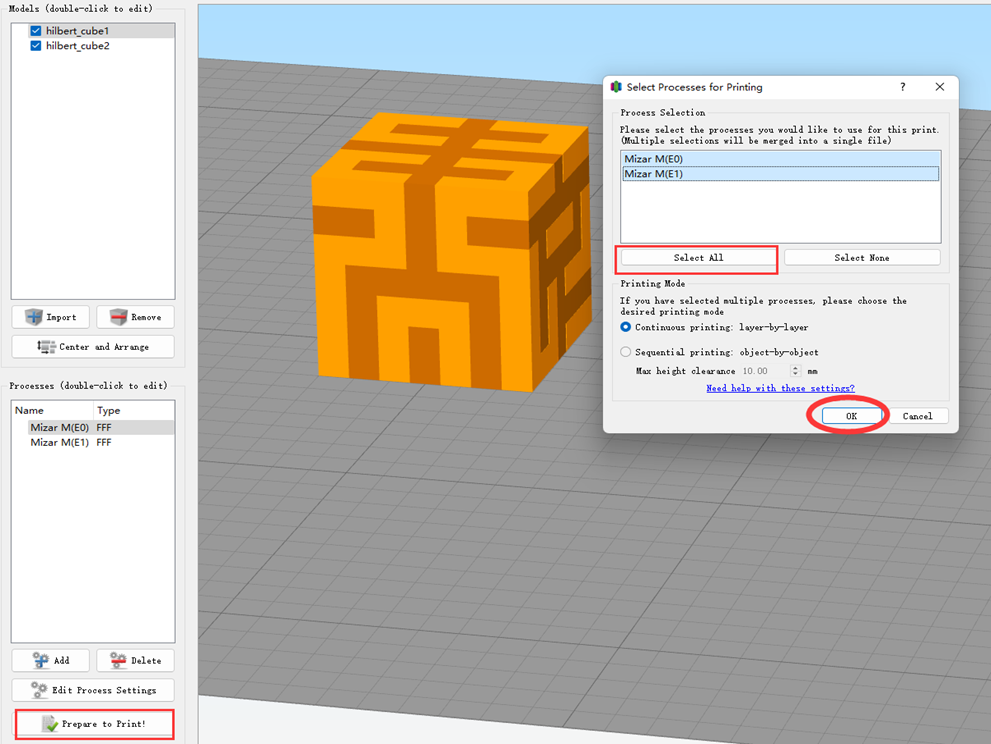

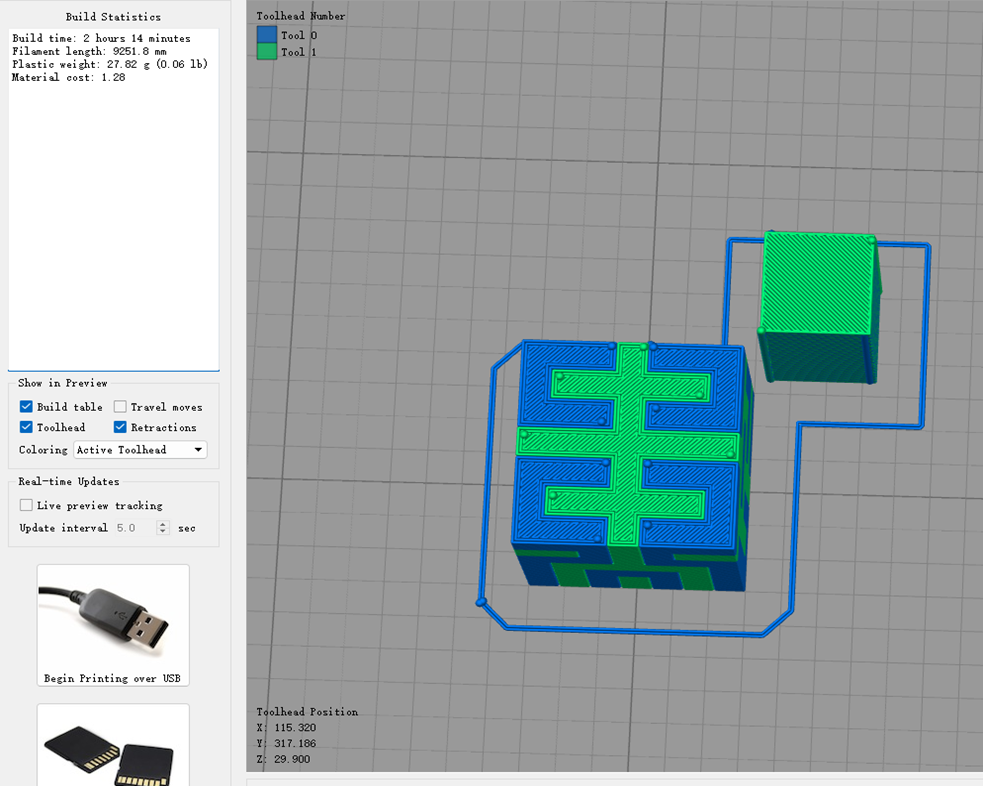

| + | Simplify3D needs to set up separate FFF processes for extruder E0/E1. Set Mizar M(E0) and Mizar M(E1) as shown below. Import 2 or more models, set the extruder head for each model, and set the size and location of the prime tower (for each | ||

| + | |||

| + | process). Select all models after Ctrl A, enter the menu and select "Align Selected Model Origins". Select two processes to complete slicing. | ||

| + | |||

| + | |||

| + | [[File:MizarMs3d1.png]] | ||

| + | |||

| + | |||

| + | [[File:MizarMs3d2.png]] | ||

| + | |||

| + | |||

| + | [[File:MizarMs3d3.png]] | ||

| + | |||

| + | |||

| + | [[File:MizarMs3d4.png]] | ||

| + | |||

| + | |||

| + | [[File:MizarMs3d5.png]] | ||

| + | |||

| + | |||

| + | [[File:MizarMs3d6.png]] | ||

| + | |||

| + | |||

| + | [[File:MizarMs3d7.png]] | ||

==== Gradient Color Printing ==== | ==== Gradient Color Printing ==== | ||

=Printer maintenance= | =Printer maintenance= | ||

Revision as of 10:07, 5 November 2022

Contents

Introduction

Thank you for supporting Geeetech Mizar M 3d printer. In case of any printer-related problem, please contact us at: https://www.geeetech.com/contactus.html or support@geeetech.com.

Product details

Main specification

Technology: FDM

Printing Thickness: 0.1-0.2mm

Printing Materials: PLA,ABS, PETG

Printing Volume: 255*255*260mm

Auto-leveling: 3D Touch Leveling Sensor

Hotbed Heating Time(110℃): 11min

Nozzle Diameter: 0.4mm

Positional Accuracy: X axis: 0.011mm Y axis: 0.011mm Z axis: 0.0025mm

Printing Accuracy: ±0.1mm

Printing Speed: 20~150mm/S

Display: 3.5-inch Color Touch Screen

Hotbed Max Temperature: 110℃

Nozzle Max Temperature: 250℃

Working temperature: 10-40℃

Electric Parameter

Power Input: 115/230V AC, 50/60Hz

Power Supply: DC24V-15A Max, 350W

Mechanical Parameter

Hotbed Size: 260*260mm

Net Weight: 10.2kg

Gross Weight: 13kg

Machine Size: 400(W)*465(L)*484(H)mm

Package Size: 522(L)*482(W)*285(H)mm

Unpacking and proper handling

Slicing

Cura

Mizar M Cura Configuration

File Path

Cura 5.X

Copy “geeetech_Mizar_M.def.json” to Ultimaker Cura 5.X\share\cura\resources\definitions

Copy “geeetech_Mizar_M_extruder0.def.json” and “geeetech_Mizar_M_extruder1.def.json”to Ultimaker Cura 5.X\share\cura\resources\extruders

Cura 4.X

Copy “geeetech_Mizar_M.def.json” to Ultimaker Cura 4.X\resources\definitions

Copy “geeetech_Mizar_M_extruder0.def.json” and “geeetech_Mizar_M_extruder1.def.json” to Ultimaker Cura 4.X\resources\extruders

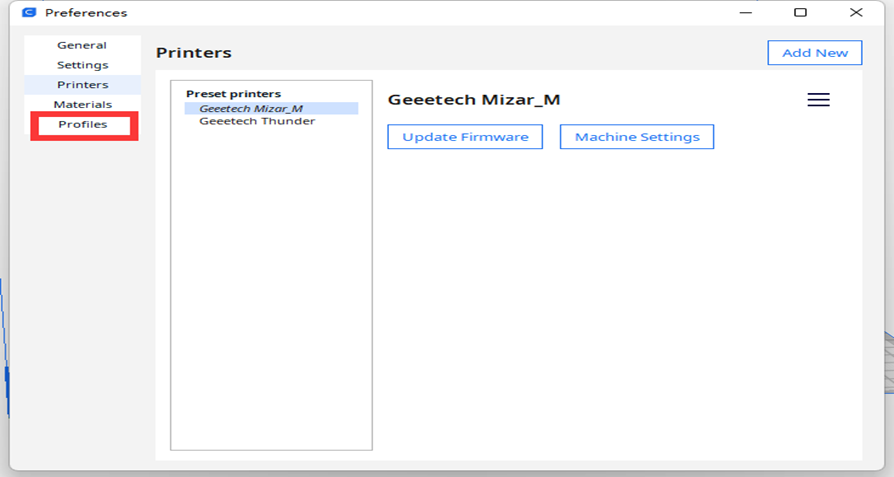

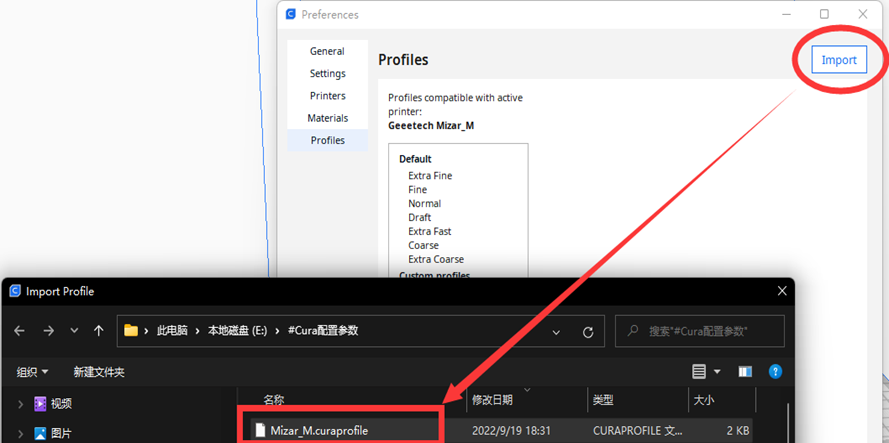

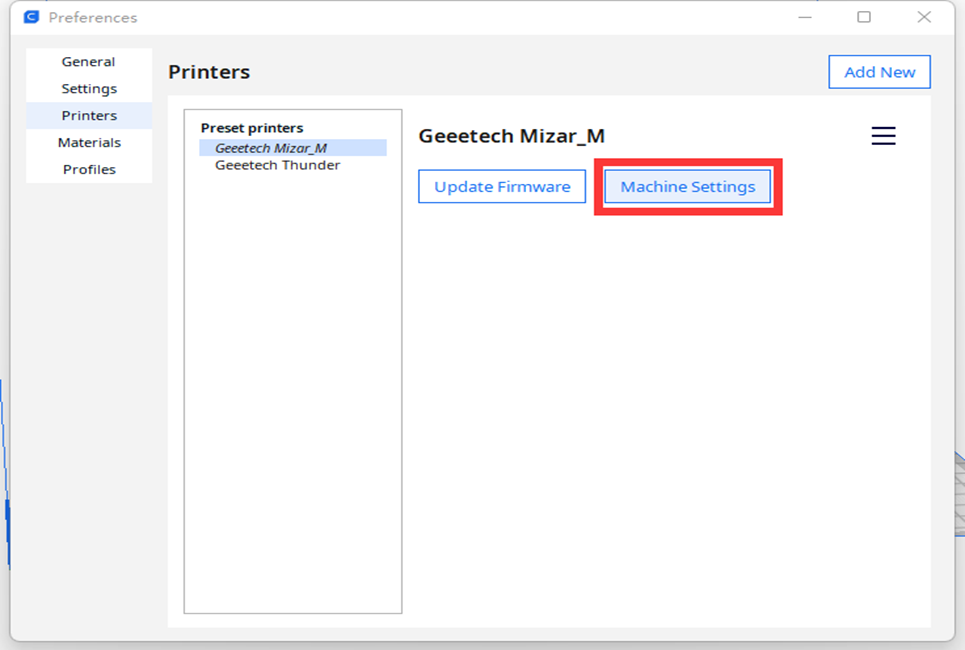

Cura Profile

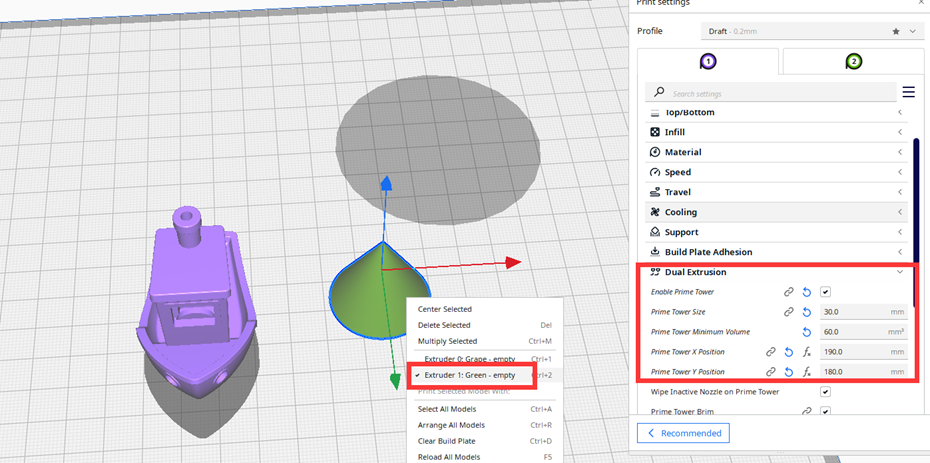

Separate Color Printing

Applied to both Gradient Color module and Separate Color module.

Import 2 or more models, respectively set the extrusion head used by each model, set the size and position of the Prime Tower.

Gradient Color printing

Make sure to install the Gradient Color module in advance.

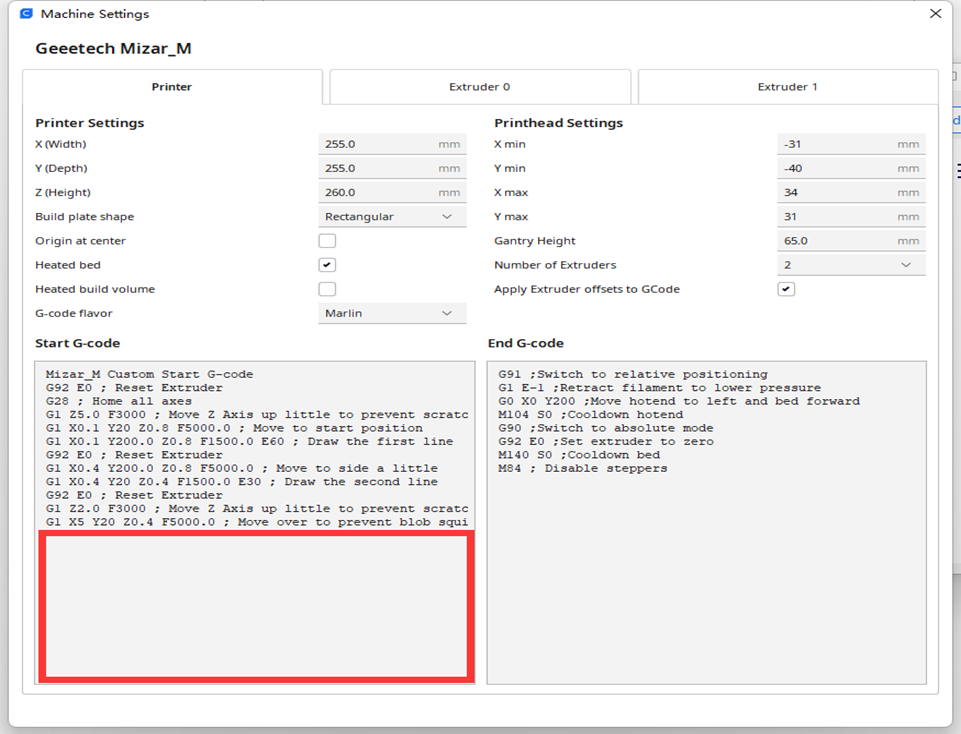

According to the different effect of the model you want, enter Mizar M printer management settings and edit different contents under the content of Start G-code. The details

are as follows. By the way, gradient color printing can disable the Prime Tower setting option.

- G-code Instructions

M163 Set a mix factor

M164 Save mix factor

M166 Gradient for Marlin 2.0

A= Start z height

Z= End z height

I= Start Virtual Tool

J= End Virtual Tool

S= Enable / disable the gradient in manual mode

T=A tool index to reassign to the gradient. If no index is given, cancel the tool assignment.

Detailed G-code instructions, please refer to the Marlin's official website https://marlinfw.org/meta/gcode/

Note: Do not use separate-color module to print mix-color gcode, clogging and damaging Teflon tube.

- Gradient color printing in a fixed proportion

M163 ;Set a mix factor M164 ;Save mix factor

For example, E0/E1 extruded 100%, 0 or 0, 100%, respectively

M163 S0 P1

M163 S1 P0

M164 S0 ;T0=100/0

Then we create the first Tools T0, which will be red.

M163 S0 P1; 100% Red

M163 S1 P0; 0% Green

Now save this color scheme in our Tools T0 we use the command:

M164 S (index), where index is our Tools, and then click:

M164 S0; Store color mixing in tools T0=100/0/0

Now we create the Tools Green, And keep it on the Tools T1:

M163 S0 P0; 0% Red

M163 S1 P1; 100% Green

M164 S1; Store color Mixing in Tools T1

- Gradient color printing in gradient proportions

Gradient for a tall vase:In this example no tool index is assigned to the Gradient. So the Gradient is enabled using M166 S1 and disabled with M166 S0.

M166 A0 Z250 I0 J1 S1

Gradient as a Virtual Tool:In this example the Gradient has been given a tool alias of 3. So the Gradient is selected with T3, and all other Tn commands will select a static

mix.

M166 A0 Z250 I0 J1 T3

T3

To use the static mix stored in T0…

M166 T

T0

M163 S0 P1

M163 S1 P0

M164 S0 ;T0=100/0

M163 S0 P0

M163 S1 P1

M164 S1 ;T1=0/100

M163 S0 P0.5

M163 S1 P0.5

M164 S2 ;T2=50/50

M166 A0 Z100 I0 J1 S1 ;Gradient Usage Instructions 1

In this example no tool index is assigned to the Gradient. So the Gradient is enabled using M166 S1 and disabled with M166 S0

M163 S0 P1

M163 S1 P0

M164 S0 ;T0=100/0

M163 S0 P0

M163 S1 P1

M164 S1 ;T1=0/100

M163 S0 P0.5

M163 S1 P0.5

M164 S2 ;T2=50/50

M166 A0 Z100 I0 J2 T3 ;Gradient Usage Instructions 2

In this example the Gradient has been given a tool alias of 3. So the Gradient is selected with , and all other commands will select a static mix.

Easy Print

Mizar M Easy Print Configuration

Mizar M Easy Print Configuration

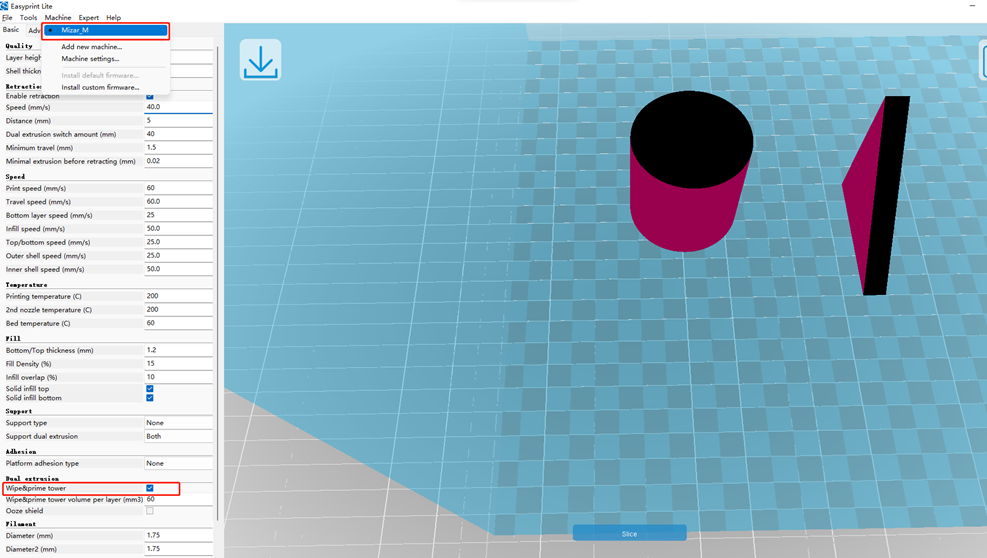

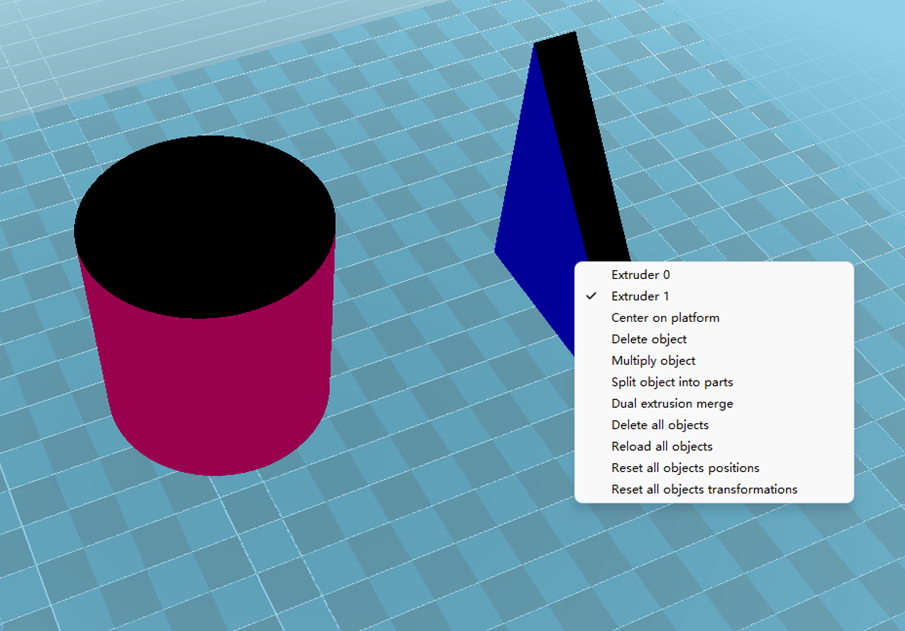

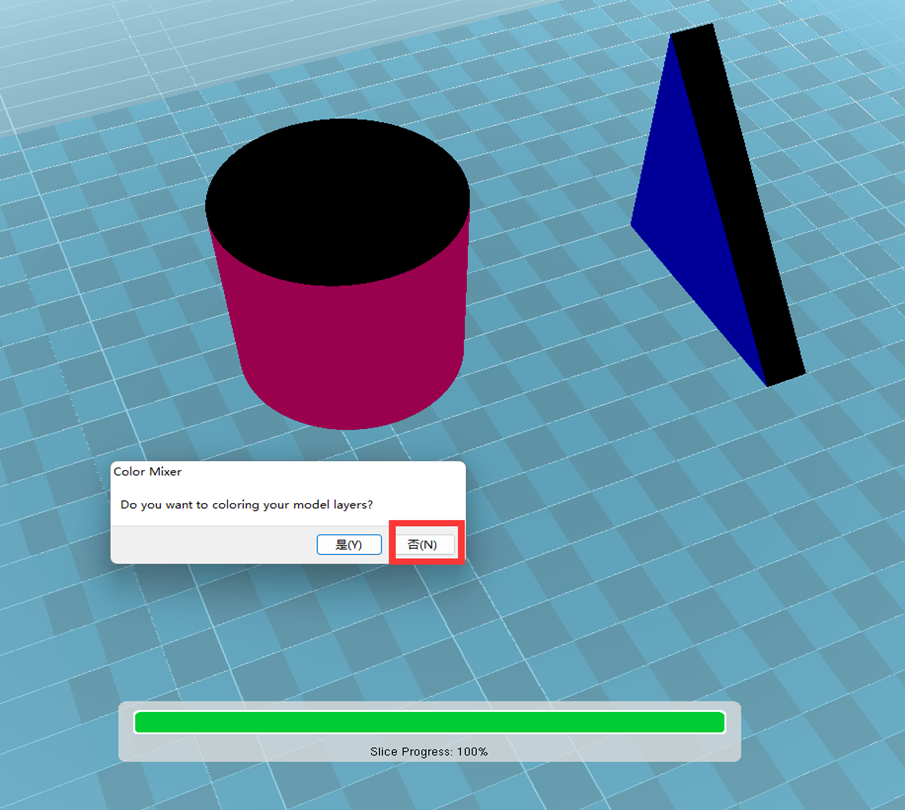

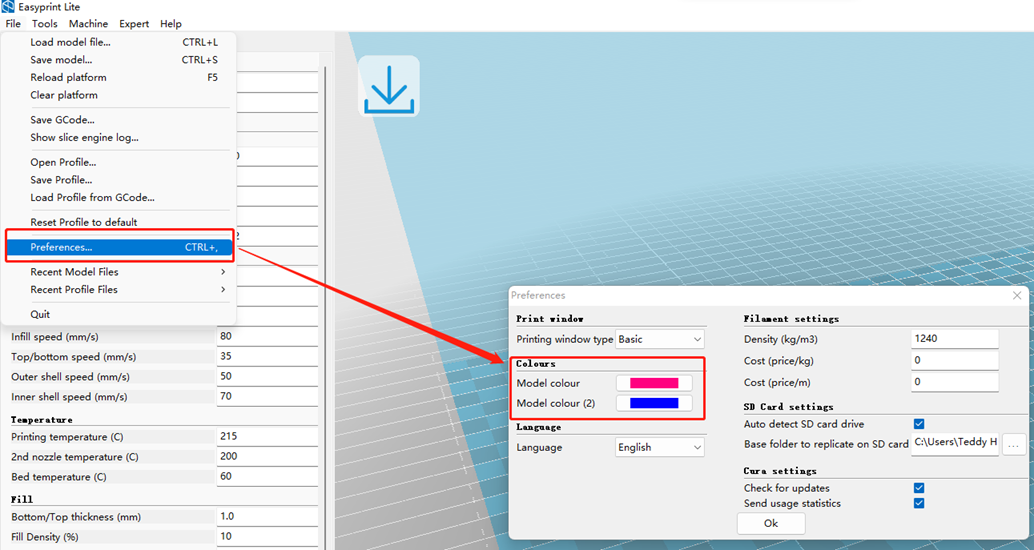

Separate Color Printing

Applied to both Gradient Color module and Separate Color module.

Import 2 or more models, the size of a single model is no more than 200M, add a prime tower, and set the extrusion head for each model. After slicing, select "No" in the prompt box for whether to mix colors.

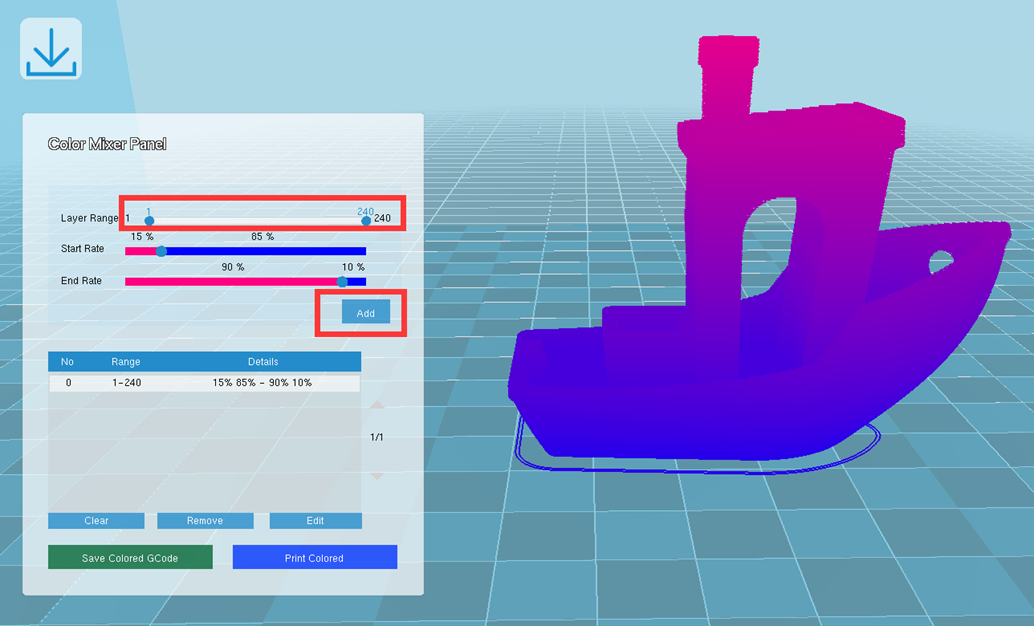

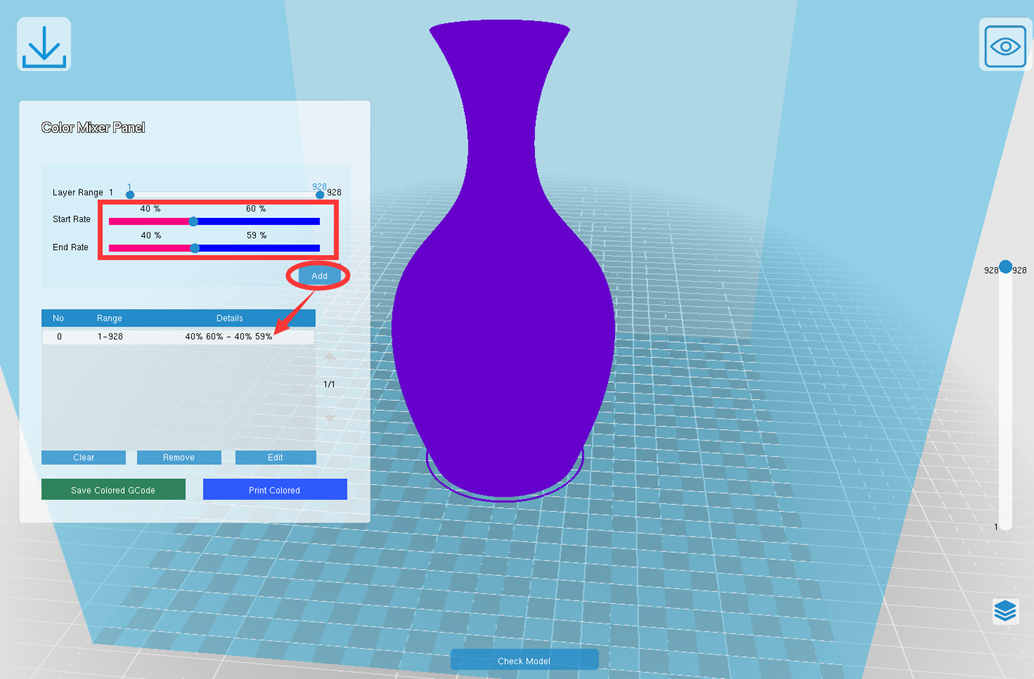

Gradient Color Printing

Make sure to install the Gradient Color module in advance.

- Mix-color printing in gradient proportions

Easy Print adopts visual color mixing effect slice, please set the E0/E1 extruder color in advance, import the model, select the color mixing effect after slicing.

- Gradient color printing in a fixed proportion

Keep the Start Rate and End Rate consistent, and click "Add" to complete the section.

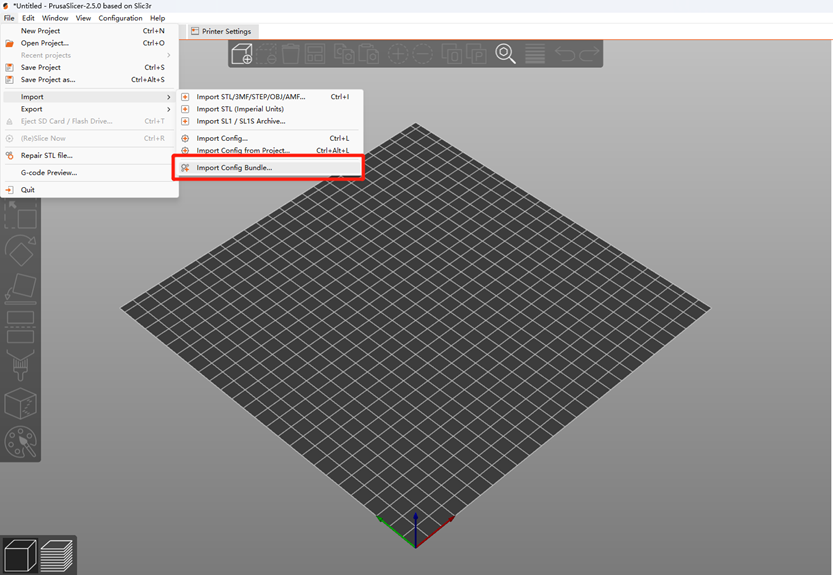

Prusa Slicer

Mizar M Prusa Configuration

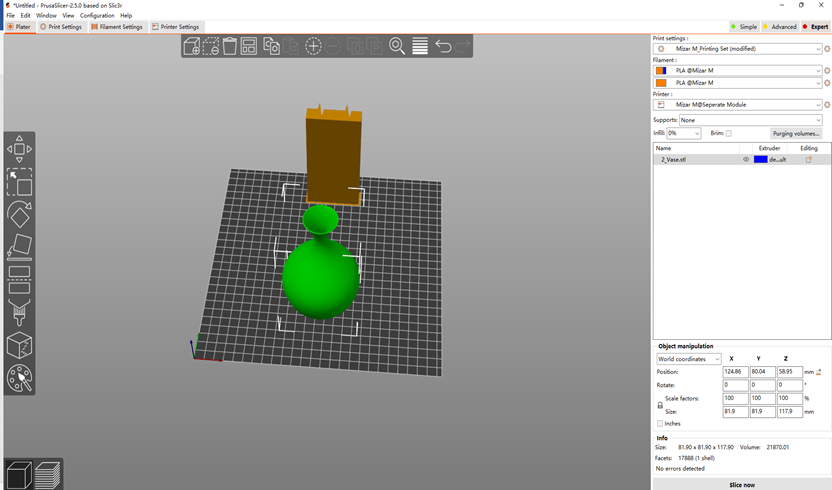

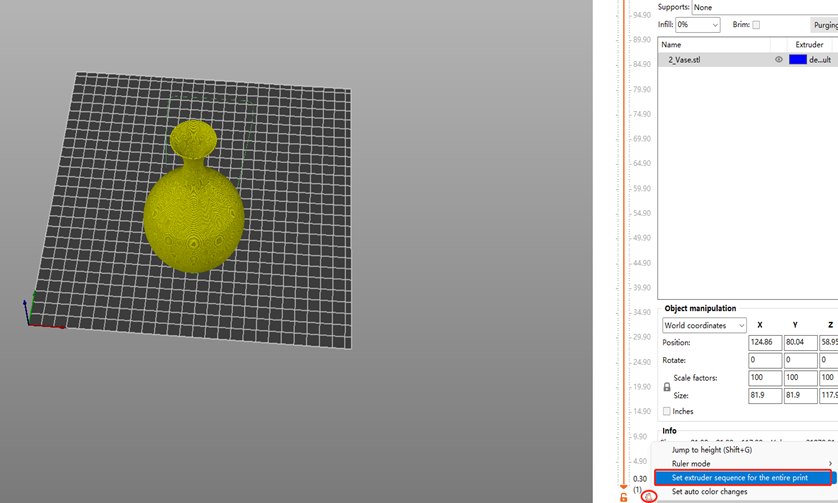

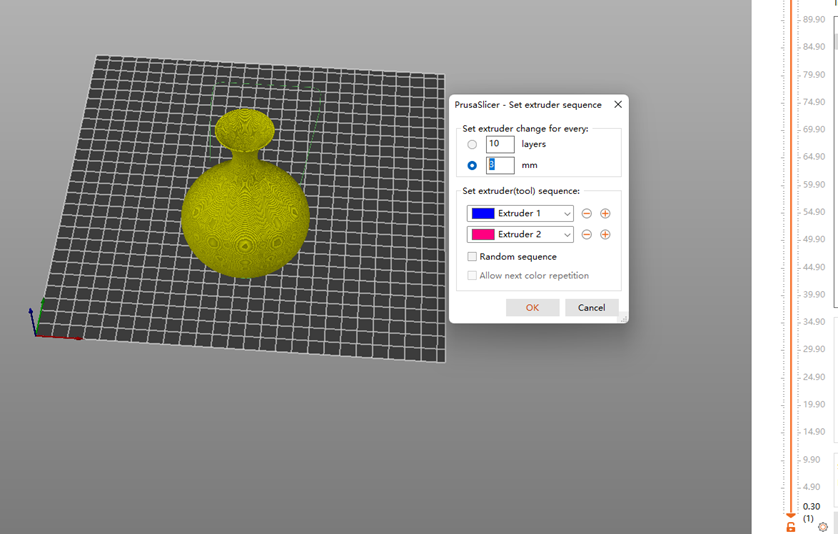

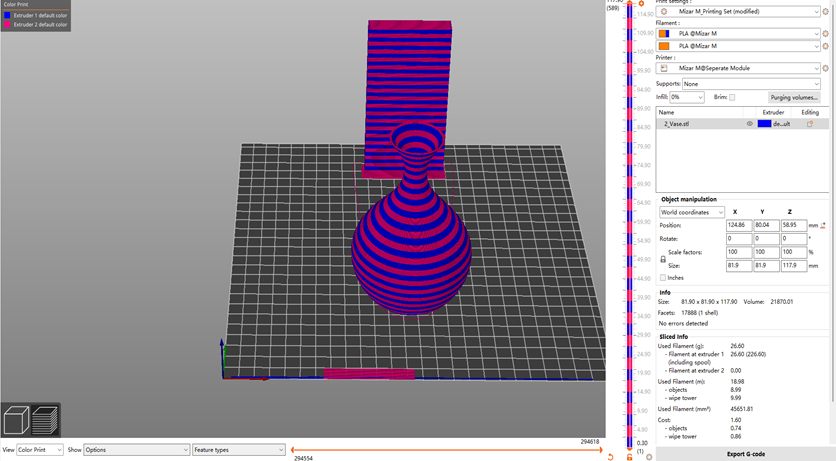

Separate Color Module

Applied to both Gradient Color module and Separate Color module.

- PrusaSlicer can print a single model with different height separations.

Import the configuration file and the stl model file, set the printing order and height after slicing, and re-slice to preview as shown in the figures.

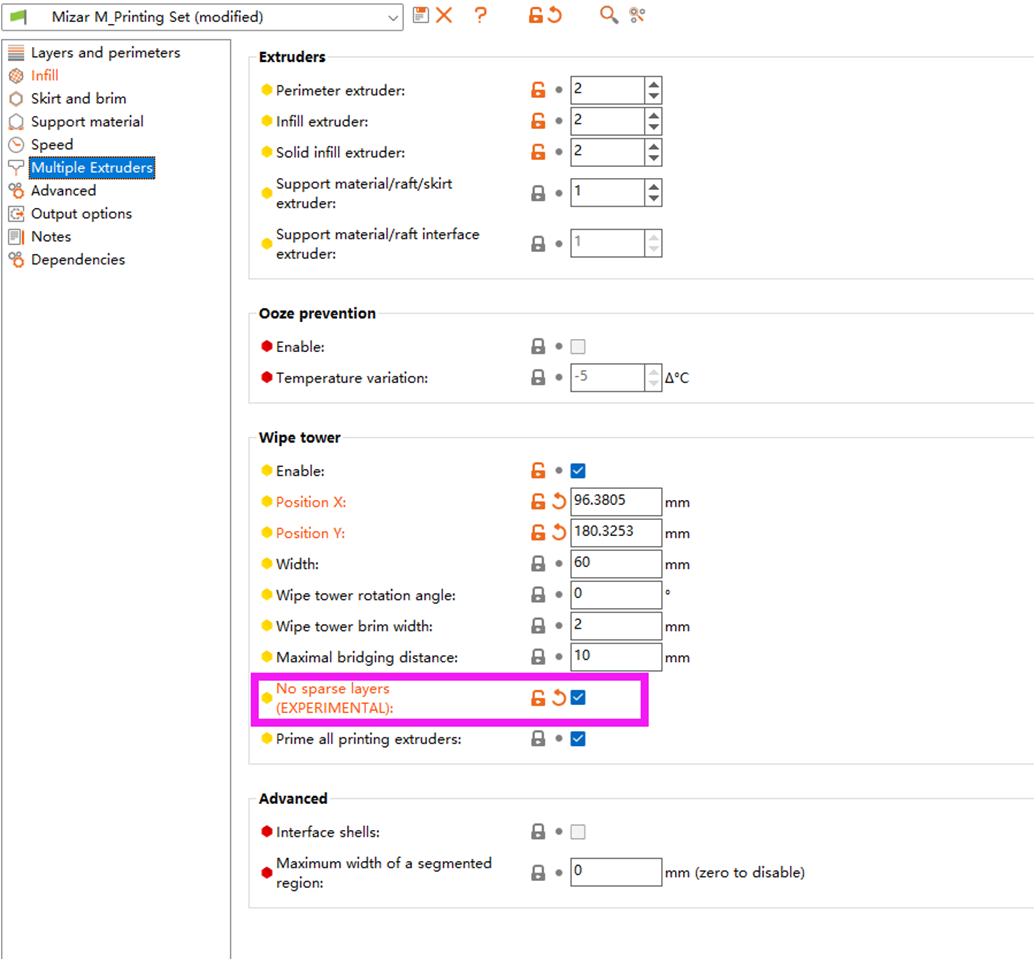

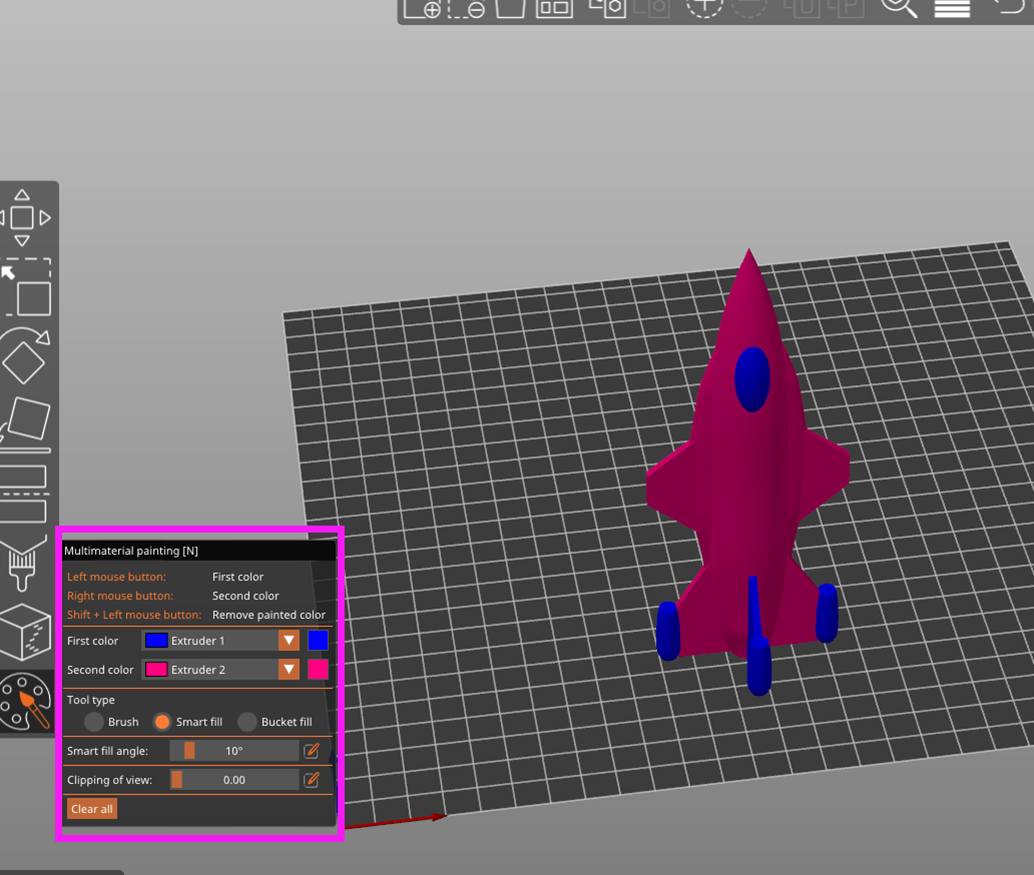

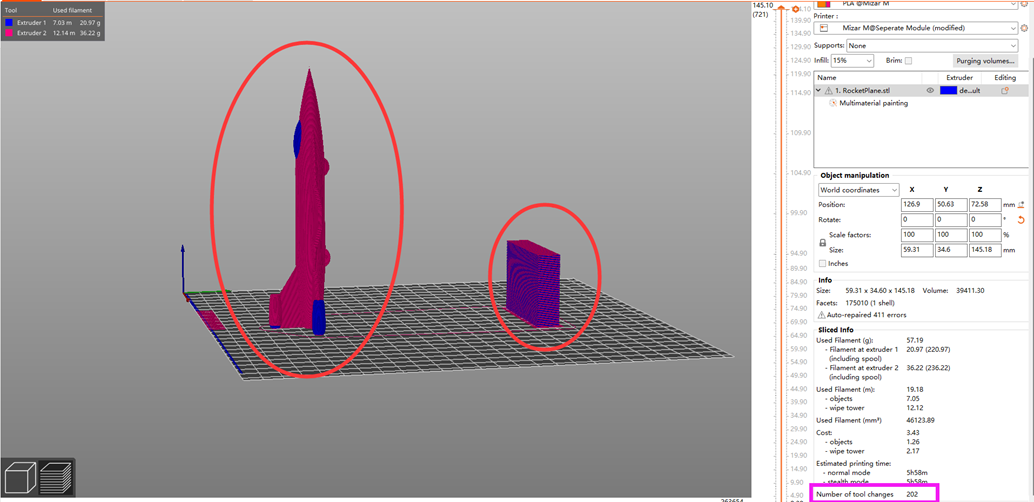

- Prusa Slicer also has the capability to color separate printing after coloring parts of a single model.

Through the tool Multimaterial painting multi-layer painting palette, the left and right keys respectively select the area to be allocated to different extruder printing, in order to prevent the printing of tainted colors or 3D Touch

impact on the prime tower, it is necessary to change the shape and volume of the prime tower appropriately. What is more worth mentioning is that the prime tower can be made smaller and save filament. The function of "No sparse

layers(EXPERIMENTAL)" in the printing setting should be enabled, but the size of the printing head should be paid attention to in this function to prevent collision with the model.

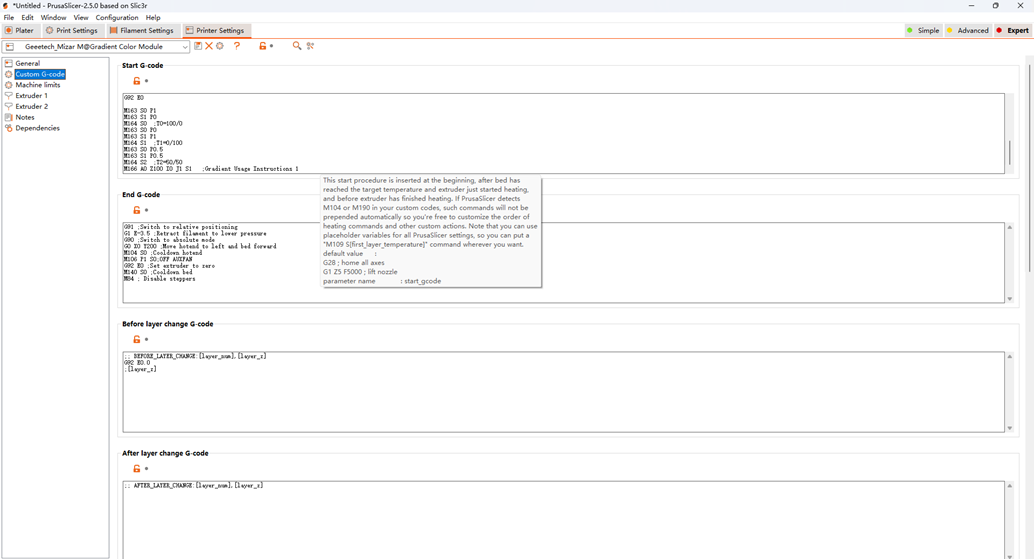

Gradient Color Module

Make sure to install the Gradient Color module in advance.

Start G-code is the same with Cura. For the script, please see Cura Gradient Color printing description.

For more frequently asked questions about PrusaSlicer Slicer, please refer to the FAQ on the official website.

https://help.prusa3d.com/article/faq-prusaslicer_1789

Simplify 3D

Mizar M Simplify 3D Configuration

Mizar M Simplify 3D Configuration

Separate Color Printing

Applied to both Gradient Color module and Separate Color module.

Simplify3D needs to set up separate FFF processes for extruder E0/E1. Set Mizar M(E0) and Mizar M(E1) as shown below. Import 2 or more models, set the extruder head for each model, and set the size and location of the prime tower (for each

process). Select all models after Ctrl A, enter the menu and select "Align Selected Model Origins". Select two processes to complete slicing.