Difference between revisions of "Geeetech Prusa I3 M201"

(→User manual) |

(→Building instruction) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 159: | Line 159: | ||

=Building instruction= | =Building instruction= | ||

| − | + | Please download the latest building instruction [https://www.geeetech.com/geeetech-prusa-i3-m201-dual-extruder-mixcolor-3d-printer-diy-kit-p-965.html here]. | |

For instruction videos, please go to our [https://www.youtube.com/playlist?list=PLODCkot3GrihN2yzDrAGAwSVQ-cbIUObs YouTube channel]. | For instruction videos, please go to our [https://www.youtube.com/playlist?list=PLODCkot3GrihN2yzDrAGAwSVQ-cbIUObs YouTube channel]. | ||

Latest revision as of 06:11, 24 October 2017

Contents

Introduction

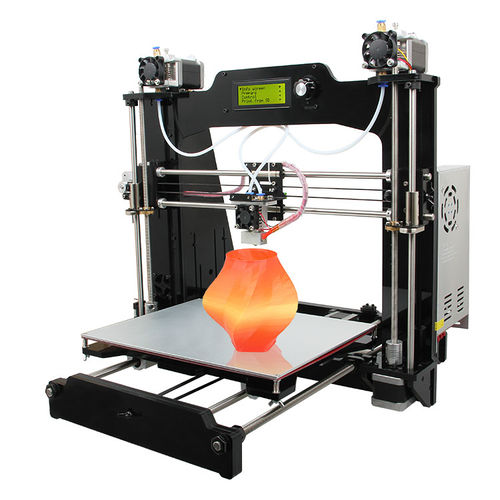

Geeetech Prusa I3 M201 is the 2-in-1-out version of our latest Prusa I3 series 3D printer. This is a fused filament fabrication printer, easy to use and also designed for DIYers and professionals alike.

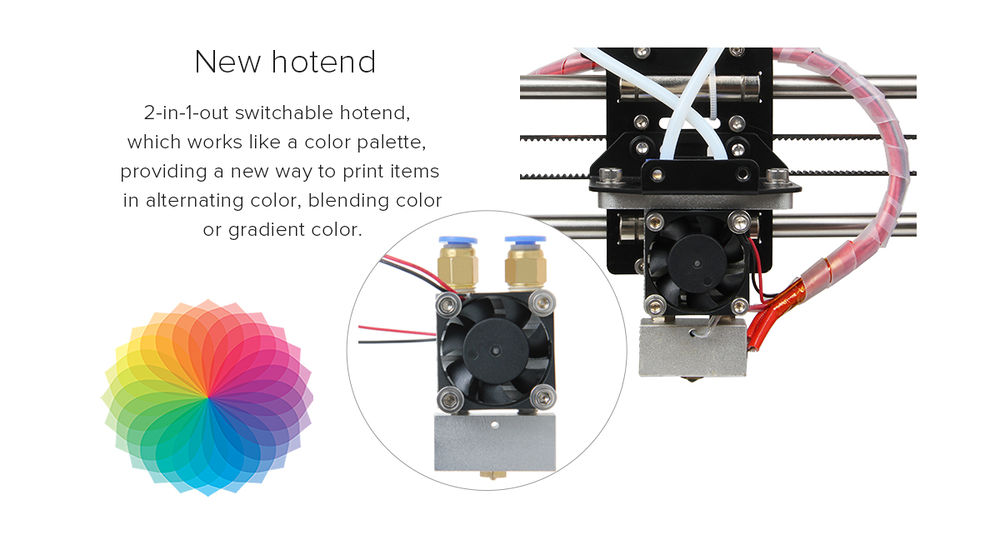

The M201 features our newly engineered the 2-in-1-out switchable hotend, that feeds 2 filaments through one nozzle. With the new 2-in-1-out hotend the M201 can work like a color palette, providing a new level of expression with your prints allowing you to create alternating colors, blending color and gradients.

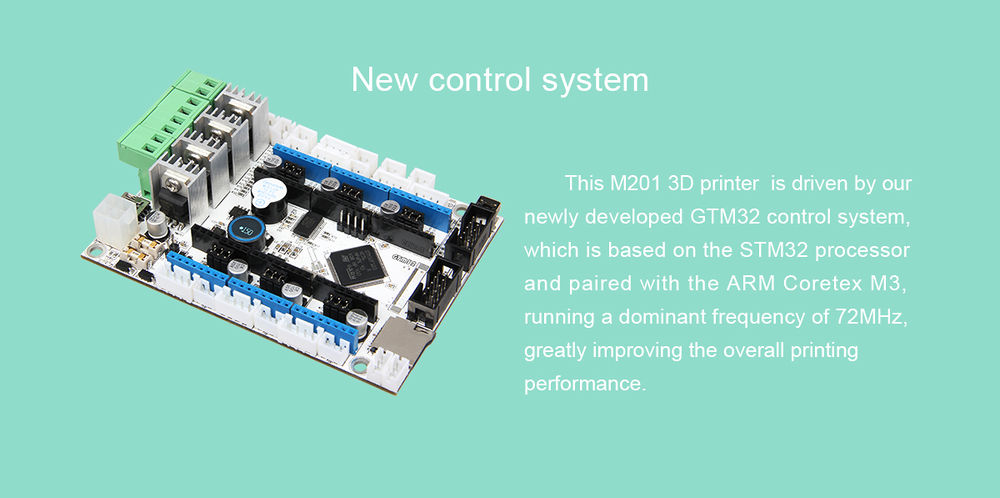

In order to achieve this we optimized the firmware that is driven by our newly developed GTM32 control system, which is based on the STM32 processor and paired with the ARM Coretex M3, running a dominant frequency of 72MHz, greatly improving the overall printing performance.

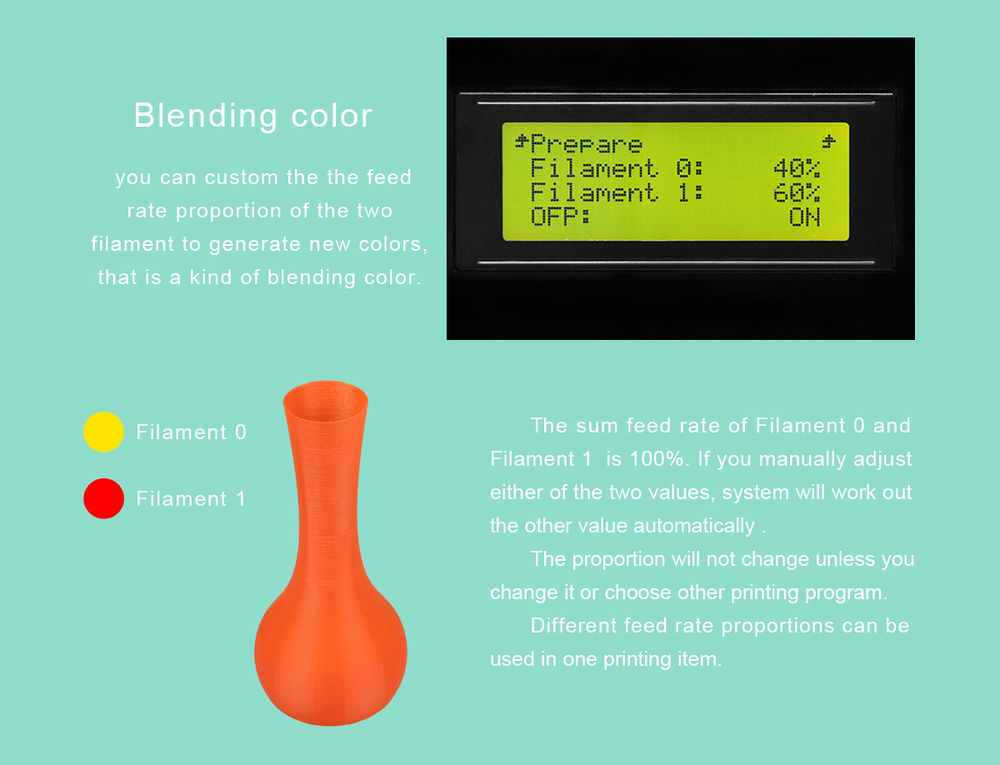

We added a new feature, the Mixer, to the interface to control the percentage of the feed rate of the two filaments. To prevent the extruder from becoming jammed from over fused filament detained in the barrel we added an over fused protect feature or OFP which is enabled by default and keeps things running smooth. When using the OFP feature the maximum feed rate of the 2 filaments is no grater than 96% and no lower than 4%.

Blending color

In Mixer, you can custom the the feed rate proportion of the two filament to generate new colors, that is a kind of blending color. The sum feed rate of Filament 0 and Filament 1 is 100%. If you manually adjust either of the two values, system will automatically work out the other value. The proportion will not change unless you change it or choose other printing scheme. Different feed rate proportions can be used in one printing item.

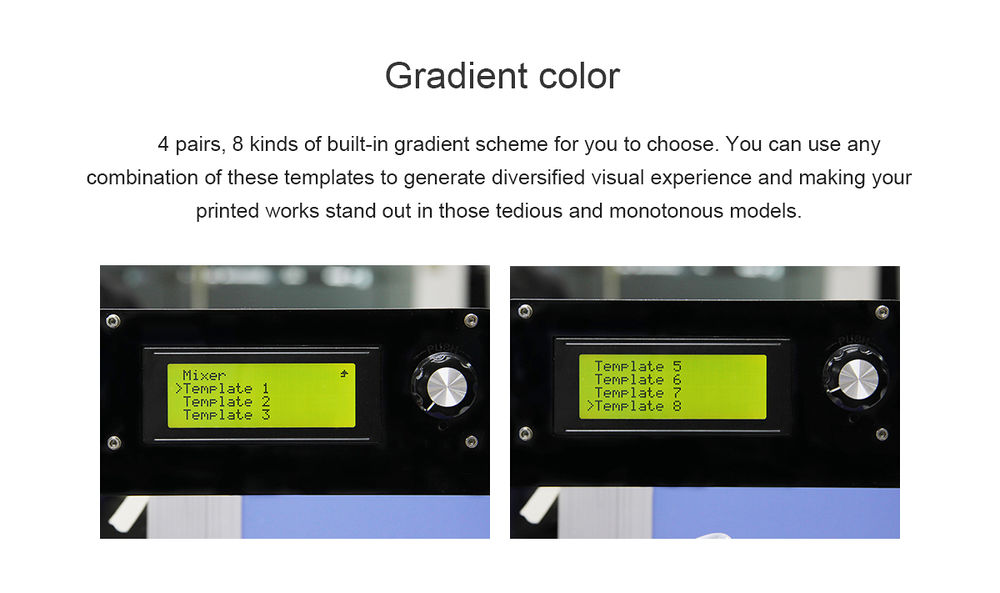

Gradient color

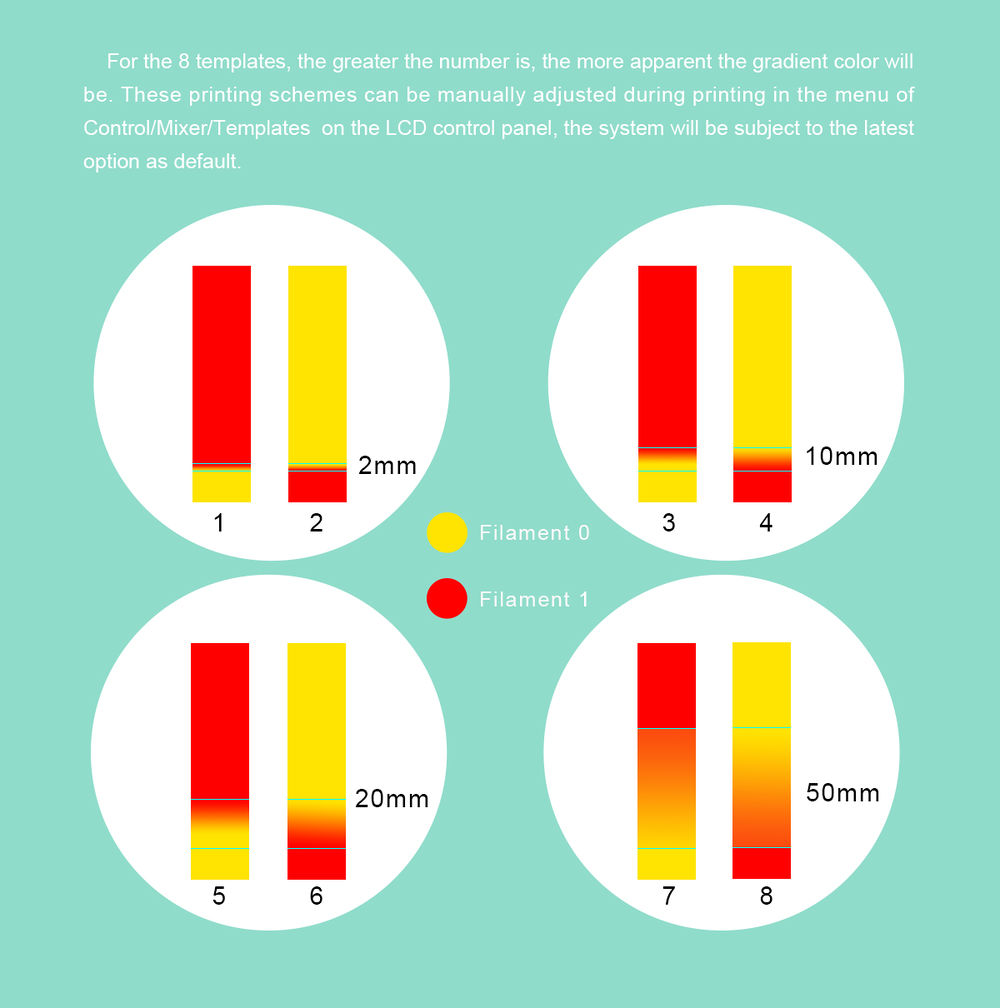

In Mixer>Templates, we have prepared 4 pairs, 8 kinds of built-in gradient templates for you to choose to print items with gradient colors. In this scheme, the feed rate proportion of two filament will vary with the printing process, and the waxing and waning proportion of two filament is reflected on the inform screen, so you can estimate the time duration and prepare for the next templates.

For the 8 templates, the greater the number is, the more apparent the gradient color will be. You can use any combination of these templates to generate items with diversified visual experience and making your printed works stand out in those tedious and monotonous models. These printing scheme can be manually adjusted in the menu of Control/Mixer on the LCD control panel easily, the system will be subjected to the latest option as default.

This M201 3D printer maintains DIY property, with which you can unleash your creativity to refit or modify it as you like. This kit is just the beginning; you can get more out of it.

Feature

1.Self-developed control system based on STM32 processor, paired with the ARM Coretex M3, running a dominant frequency of 72MHz, greatly improving the overall printing performance.

2.Optimized firmware, with new feature of adjusting the proportion of feed rate from two extruders to print items with blending color or gradient colors.

3. 2-in-1-out switchable hotend, works like a color palette, providing a new way to print items in two different colors or gradient colors.

4. 280x210x200mm printing volume, able to printer larger models than most of the I3 printers on the market.

5. Up to 0.1mm printing precision, matching competitors that costs 10 times more on the market.

6. With LCD 2004 controller and SD card reader, support stand-alone printing.

7. Super-flat aluminum alloy print surface for better adherence.

8. 3D printing filaments compatible: PLA, ABS

Upgrade

In last version of firmware, users can custom blending printing effect. However, if users want to get gradient color effect, they can only choose from the 8 kinds of fixed templates which are preset in the firmware. In order to achieve more kinds of printing effects and more gradient styles, we add a practical feature to Firmware so that users can customize gradient template. Thus we can set different gradient color effects according to the design need for different models.

In addition, in the previous firmware, there are occasional long pause problems during printing. This will cause the fused plastic piled up at one place, which will affect the appearance of printed part or even ruin the whole object. Therefore, we repaired the bug in version firmware1.0.0, and the printing quality will be greatly improvement.

New added feature

1. Customizable gradient templates. Users can set custom parameters of Start Gradient Percent, End Gradient Percent, Start Height, and End Height.

2. During the printing process, as long as the actual temperature reaches the point which is 5℃ lower than the preset temperature, the printer will start printing. It can not only ensure the printing temperature but also reduce the waiting time of printing.

Bug Repair

1. Modification of the default value of steps per mm. More accurate printing dimension and improved printing quality.

2. The maximum temperature of the hotbed is limited to 110℃, which is more adaptable for printing with ABS material.

3. Solving the occasional long pause problem during the printing process. Long pause during the printing process will result in the printed part melted by the hot head and forming a defective appearance. Meanwhile the raised filament may cause movement dislocation of the extruder and result in the complete failure of printing in the end.

Custom gradient template

Custom template allows user to set the parameters of gradient color printing. It provides six customizable templates for user to set and they are named as Custom1 to Custom6. User can set under the Mixer >Custom menu. Each template includes parameters of Start Gradient Percent, End Gradient Percent, Start Height, and End Height. perform a Store Memory to Save it when the setting is done.

Next i will show you how to set and use a customized template.

NOTE:Parameters Setting Instructions:

1. All the settings are set based on Filament0 by default.

2. According to the work principle of Mixer, the sum feeding rate of Filament0 and Filament1 is 100%. After Filament0 is set, the system will automatically calculate the corresponding feeding rate of Filament1.

3. Start percent and end percent can be set at will. The sum of them is not always 100%. Users can adjust it according to their requirements.

E.g., you can set the start percent of Filament0 as 30% and the end percent 60%.

4.Start height and end height are print heights above the bed not the current printing height. Start height and end height must be greater than current printing height, otherwise they will be regarded as invalid. For example, current height is 40mm above the bed, but the start height in the template setting is 20mm and the end height is 30mm. It has overlapped part with current print height, so the system will automatically ignore this template and continue printing with the current template.

5.When one templates is finished, printing will continue with the feed rate percent that is fixed, without gradient effect, until you choose a new template.

Specification

Printing specifications

Print technology:FDM/FFF

Build volume: 280 x210x200mm

Printing resolution: 0.1-0.3mm

Print Speed: 60-110 mm/s

Filament diameter: 1.75mm

Nozzle diameter: 0.4mm

Filament type: PLA, ABS

Software

Operating system: Windows/Mac/Linux

Control software: Repetier-Host, Printrun

File format: .STL,G-code

Temperature

Max heated bed temperature: about 110 °C

Max extruder temperature: about 240°C

Electrical Power supply:

Input: 115V/1.5A or 230V/0.75A

Output:DC24V/0-15A

Connectivity: USB, SD card (support stand-alone printing)

Mechanical

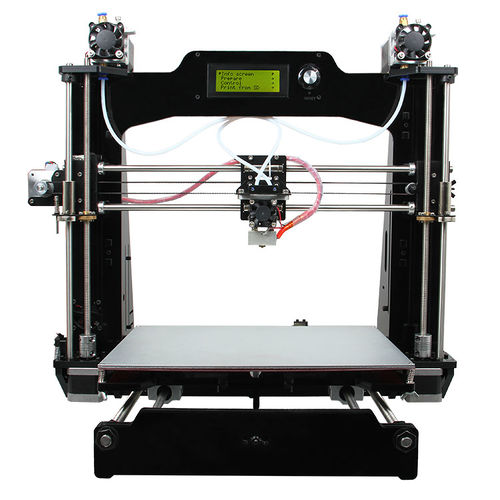

Frame: Laser-cut Acrylic plate of 8 mm thickness

Build Platform: Super-flat aluminum alloy+ heatbed

XYZ Rods: Wear-resistant, stainless steel

Stepper Motors: 1.8°step angle with 1/16 micro-stepping

Physical Dimensions & Weight

Machine Dimension: 510x 450 x 450 mm

Shipping box Dimension: 510 x 470 x 155 mm

Machine Net weight: 9.5kg

Machine Shipping weight: 10.5kg

more details

Building instruction

Please download the latest building instruction here.

For instruction videos, please go to our YouTube channel.

User manual

Download quick start user manual here.

more

To buy prusa I3 M201,please go to our online store.