Difference between revisions of "Acrylic Prusa I3 pro B"

(→Features) |

(→Features) |

||

| Line 17: | Line 17: | ||

6. MK8 extruder ensures smaller layers and higher resolution, make models and objects.General Tips & Tricks for printing with Flexible and wood | 6. MK8 extruder ensures smaller layers and higher resolution, make models and objects.General Tips & Tricks for printing with Flexible and wood | ||

| + | =specifications= | ||

| + | |||

| + | Printing specifications | ||

| + | |||

| + | Print technology: Fused Filament Fabrication | ||

| + | |||

| + | Build volume: 200 x200x180mm | ||

| + | |||

| + | Layer resolution: 0.1-0.3mm | ||

| + | |||

| + | Positioning Precision: 0.1-0.3mm | ||

| + | |||

| + | Filament diameter: 1.75mm, 3mm | ||

| + | |||

| + | Nozzle diameter: 0.3mm, 0.35mm, 0.4 mm, 0.5mm | ||

| + | |||

| + | Filament type: ABS/ PLA/Flexible PLA/ Wood /Nylon | ||

| + | |||

| + | |||

| + | Software: | ||

| + | |||

| + | Operating system: Windows/Mac/Linux | ||

| + | |||

| + | Control software: Repetier-Host, Printrun | ||

| + | |||

| + | File format: .STL. G-code | ||

| + | |||

| + | |||

| + | Temperature: | ||

| + | |||

| + | Max heated bed temperature: about 110°C | ||

| + | |||

| + | Max extruder temperature: about 240°C | ||

| + | |||

| + | Electrical: | ||

| + | |||

| + | Power supply: Input: | ||

| + | |||

| + | 115V/1.5A 230V/0.75A | ||

| + | |||

| + | Output:DC12V/0-15A | ||

| + | |||

| + | Connectivity: USB, SD card (support off-line printing) | ||

| + | |||

| + | Mechanical: | ||

| + | |||

| + | Body: Acrylic plate of 8 mm thickness (black/ transparent) | ||

| + | |||

| + | Build Platform: Borosilicate glass + MK2A heatbed | ||

| + | |||

| + | XYZ Rods: Wear-resistant, stainless steel | ||

| + | |||

| + | Stepper Motors: 1.8° step angle with 1/16 micro-stepping | ||

| + | |||

| + | Physical structure: Reprap | ||

| + | |||

| + | Physical dimensions: | ||

| + | |||

| + | Without spool: 45 x 44 x 44 cm | ||

| + | |||

| + | With spool: 45 x 44 x 68 cm | ||

| + | |||

| + | Shipping box: 52 x 42 x 23 cm | ||

| + | |||

| + | Net weight: 8. 5 kg | ||

| + | |||

| + | |||

| + | |||

| + | |||

'''Filament:''' | '''Filament:''' | ||

1. The melting temperature is different for different type of filament; please refer to the suggested temperature you are using. The guideline for an optimal printing temperature is at approximately 210°C for flexible and 230°C for wood filament. The recommended heated bed temperature varies between ± 60˚C and ± 100˚C. | 1. The melting temperature is different for different type of filament; please refer to the suggested temperature you are using. The guideline for an optimal printing temperature is at approximately 210°C for flexible and 230°C for wood filament. The recommended heated bed temperature varies between ± 60˚C and ± 100˚C. | ||

Revision as of 08:32, 4 May 2015

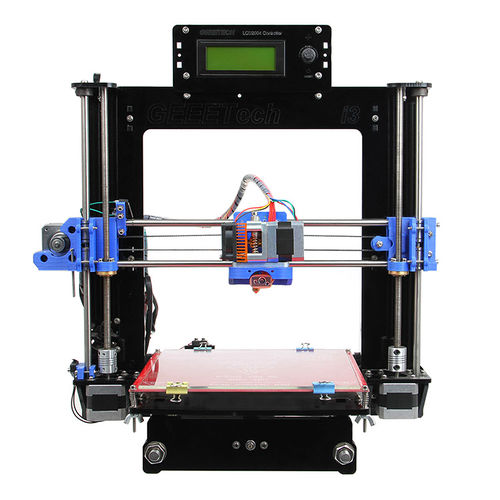

Introduction

This Geeetech I3 pro B 3D printer is designed and manufactured by Shenzhen Getech Co., Ltd based on Geeetech I3 pro, except its simple assembly, easy debugging and more stable performance, compared with the I3 pro, I3 pro B features newly added potential for 3D prints—support 5 types of filament: ABS, PLA, Wood, Nylon, flexible PLA and filament, create flexible hinges, joints, shaped parts; enable you to get the most out of your 3D Printer.

Features

1.Re-designed barrel of extruder to support multiple filaments: ABS/PLA/Flexible PLA/WOOD, making 3D printing more flexible.

2. Further simplified structure means fast assembly and easy adjustment, which saves you both time and energy as well as speeds up the molding of your innovative products and ideas. It usually takes up to 3 days for a DIYer to assemble the previous I3, not to mention the post-adjustment and debugging work. As to this I3 of Acrylic Frame, however, you can save 70% of time.

3. Enhanced stability and reliability. Geeetech I3 pro B adopts 8 mm-thick acyclic plates, also you can choose the piano-black one and the transparent one, and both colors look good.

4. The PSU (power supply unit) is assembled together with the printer; which saves you a lot of space and can avoid unnecessary electrical trouble.

5. All the cables and wires are well arranged to make it more neat and easy to operate.

6. MK8 extruder ensures smaller layers and higher resolution, make models and objects.General Tips & Tricks for printing with Flexible and wood

specifications

Printing specifications

Print technology: Fused Filament Fabrication

Build volume: 200 x200x180mm

Layer resolution: 0.1-0.3mm

Positioning Precision: 0.1-0.3mm

Filament diameter: 1.75mm, 3mm

Nozzle diameter: 0.3mm, 0.35mm, 0.4 mm, 0.5mm

Filament type: ABS/ PLA/Flexible PLA/ Wood /Nylon

Software:

Operating system: Windows/Mac/Linux

Control software: Repetier-Host, Printrun

File format: .STL. G-code

Temperature:

Max heated bed temperature: about 110°C

Max extruder temperature: about 240°C

Electrical:

Power supply: Input:

115V/1.5A 230V/0.75A

Output:DC12V/0-15A

Connectivity: USB, SD card (support off-line printing)

Mechanical:

Body: Acrylic plate of 8 mm thickness (black/ transparent)

Build Platform: Borosilicate glass + MK2A heatbed

XYZ Rods: Wear-resistant, stainless steel

Stepper Motors: 1.8° step angle with 1/16 micro-stepping

Physical structure: Reprap

Physical dimensions:

Without spool: 45 x 44 x 44 cm

With spool: 45 x 44 x 68 cm

Shipping box: 52 x 42 x 23 cm

Net weight: 8. 5 kg

Filament:

1. The melting temperature is different for different type of filament; please refer to the suggested temperature you are using. The guideline for an optimal printing temperature is at approximately 210°C for flexible and 230°C for wood filament. The recommended heated bed temperature varies between ± 60˚C and ± 100˚C.

2. It is recommended to significantly lower your printing speed (compared to printing with PLA, or ABS) when printing with Flexible filament and wood filament.Specifications

please refer here for more detaied introduction.