Difference between revisions of "Geeetech Delta Rostock mini"

(→Introduction) |

(→Introduction) |

||

| Line 1: | Line 1: | ||

=Introduction= | =Introduction= | ||

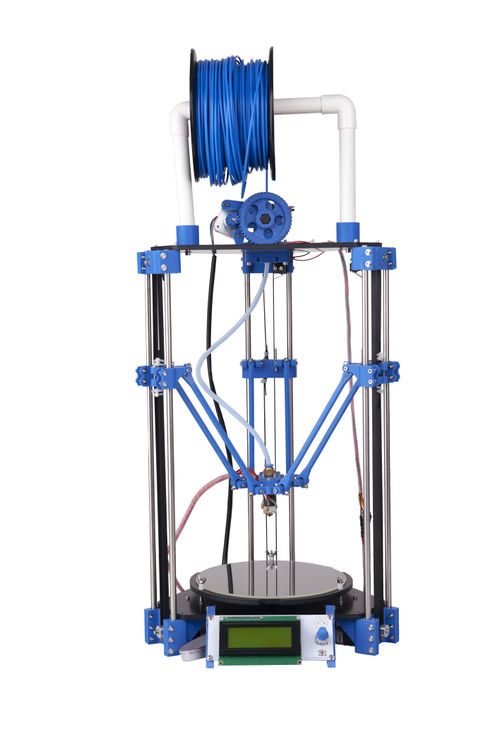

| − | [[File:Geeetech Delta Rostock mini.jpg|500px|]] | + | [[File:1 Geeetech Delta Rostock mini.jpg|500px|]] |

The Rostock mini made by Geeetech is a delta 3D printer based on the modified design of the original Rostock created by Johann. The printer is designed to have a smaller build volume allowing for a smaller, more compact, portable, and desktop friendly version of the delta RepRap design. | The Rostock mini made by Geeetech is a delta 3D printer based on the modified design of the original Rostock created by Johann. The printer is designed to have a smaller build volume allowing for a smaller, more compact, portable, and desktop friendly version of the delta RepRap design. | ||

Revision as of 02:09, 19 November 2014

Introduction

The Rostock mini made by Geeetech is a delta 3D printer based on the modified design of the original Rostock created by Johann. The printer is designed to have a smaller build volume allowing for a smaller, more compact, portable, and desktop friendly version of the delta RepRap design. Using OpenSCAD, the parametric nature of the design files allows for print surfaces to be configured from as small as the default 152x152 mm (6x6 inches) all the way to 300x300 mm (12x12 inches) or more. Further, construction parameters such as the length of the drive belts, diagonal rods, and a laser cuttable frame, as well as the firmware parameters such as diagonal rod length and delta radius are all automatically calculated based on the size of the specified print surface.

Features:

1. Mini- size & light weight, more compact & portable compared with other Delta RepRap design.

2. Fixed printing platform, parallel kinematic XYZ axes with low accumulated error, ensuring high precision & speed of printing.

3. Bakelite print platform with treatment of sand blast and anodization; polished oxidized high borosilicate tempered glass. Compared with aluminum sheet and acrylic sheet, the has advantages of high mechanical strength, good insulation, good heat resistance and good corrosion resistance

Main parameters

Physical Dimensions & Weight

Machine size: 280mm*340mm*700mm (L/W/H)

Packing size: 510*410*260mm (L/W/H)

Weight: 9000g

Printing Specifications

Printing Technology: Fused Filament Fabrication,FFF

Operating system: Windows/Mac/Linux

Slicing software: Cura / Repetier

Control software: Repetier-Host

Data format: all 3D files converted into STL file

Layer Resolution: 0.05mm

Build Volume: 150 x 150 x 180mm

Filament Type: ABS/ PLA (ABS used only when hot bed is equipped)

Filament Diameter : 1.75mm/3mm

Nozzle Diameter: 0.3mm, 0.35mm, 0.4mm & 0.5mm optional

Location accuracy: 0.1mm

Temperature

Max Heated Bed Temp: 110 ℃

Max Extruder Temp: 240 ℃

Mechanism

Physical structure: Delta

Frame: AISI304 stainless steel optical axis with Bakelite of 6mm thickness

Build platform: tempered glass with 198mm diameter and 3mm thickness

Movement mode: printing platform fixed; X, Y and Z axes all subject to parallel movement

Extrusion system: Bowden feed

Motors: nema17, 2.5A

Electrical

Input AC 220V/2.4A(110V/4.8A),Output DC 12V/29A

Connectivity:USB or SD card