Difference between revisions of "PEEK J-head short-distance"

(→Description) |

(→Product Introduction) |

||

| (8 intermediate revisions by the same user not shown) | |||

| Line 6: | Line 6: | ||

parts to a bare minimum. The [http://www.geeetech.com/assembled-jhead-hot-end-030350405mm-nozzle-for-1753mm-p-748.html J-Head Hot End] can easily and well interface with the most popular RepRap extruders. | parts to a bare minimum. The [http://www.geeetech.com/assembled-jhead-hot-end-030350405mm-nozzle-for-1753mm-p-748.html J-Head Hot End] can easily and well interface with the most popular RepRap extruders. | ||

| − | The filament path is same with teh one of an already proven design, it can be used to print reliably with both [http://www.geeetech.com/?main_page=index&cPath=83 ABS] and [http://www.geeetech.com/?main_page=index&cPath=83 PLA]. If using PLA, it requires a small fan to provide air-flow through the cooling vents milled in the sides of the nozzle holder. Besides, the Hot End has another two advantages. Heat transmission is more efficiency as there is no thermal junction where a separate heater screws onto the nozzle. And a resistor is used as a heater. There is no need to wrap nichrome wire or to bake a heater core. | + | The filament path is same with teh one of an already proven design, it can be used to print reliably with both [http://www.geeetech.com/?main_page=index&cPath=83 ABS] and [http://www.geeetech.com/?main_page=index&cPath=83 PLA]. If using [http://www.geeetech.com/?main_page=index&cPath=83 PLA], it requires a small fan to provide air-flow through the cooling vents milled in the sides of the nozzle holder. Besides, the Hot End has another two advantages. Heat transmission is more efficiency as there is no thermal junction where a separate heater screws onto the nozzle. And a resistor is used as a heater. There is no need to wrap nichrome wire or to bake a heater core. |

This product is of [http://www.geeetech.com/assembled-jhead-hot-end-030350405mm-nozzle-for-1753mm-p-748.html J-head Hot End] design. It adopts high-quality PEEK heat-insulated pipe and duralumin alloy nozzle, with Teflon heat-insulated pipe built in, which prevents blockage effectively and is easy to clean. Besides, its surface is covered with anodic oxide coating, which can resist oxidation corrosion and increase nozzle hardness, thus ensuring finer and more stable printing. | This product is of [http://www.geeetech.com/assembled-jhead-hot-end-030350405mm-nozzle-for-1753mm-p-748.html J-head Hot End] design. It adopts high-quality PEEK heat-insulated pipe and duralumin alloy nozzle, with Teflon heat-insulated pipe built in, which prevents blockage effectively and is easy to clean. Besides, its surface is covered with anodic oxide coating, which can resist oxidation corrosion and increase nozzle hardness, thus ensuring finer and more stable printing. | ||

| Line 15: | Line 15: | ||

The idea of using the PTFE tubing as a liner, from the Cold End to the tip, was borrowed from the Makerbot Mk V extruder design. | The idea of using the PTFE tubing as a liner, from the Cold End to the tip, was borrowed from the Makerbot Mk V extruder design. | ||

| + | |||

| + | |||

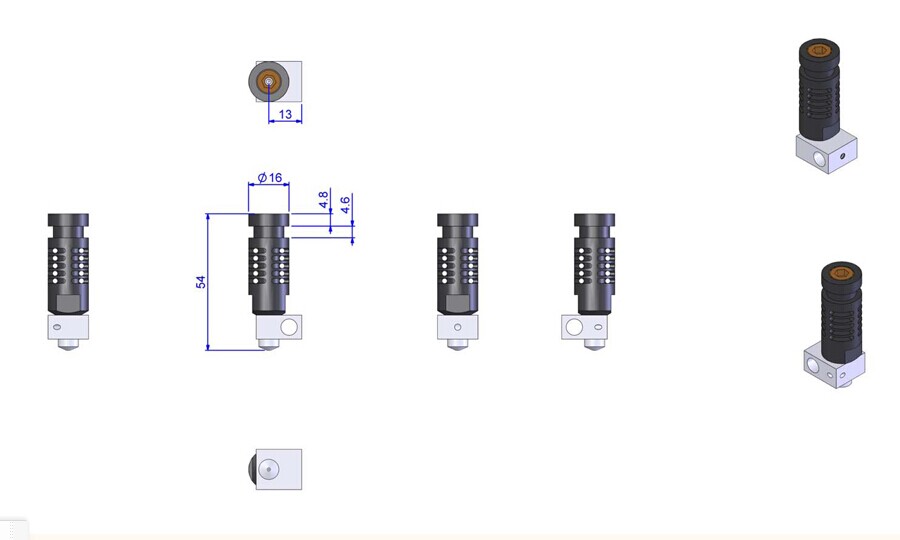

| + | [[File:PJ-headZZT.jpg]] | ||

| + | [[File:PJ-headZZT2.jpg]] | ||

== Advantages== | == Advantages== | ||

| Line 20: | Line 24: | ||

* Internally, the filament path is identical to that of an already proven design. | * Internally, the filament path is identical to that of an already proven design. | ||

* The design is simple as the number of custom machined parts is kept to a minimum. | * The design is simple as the number of custom machined parts is kept to a minimum. | ||

| − | * If necessary, the PTFE liner can be replaced by using an off-the-shelf piece of PTFE tubing. | + | * If necessary, the [http://www.geeetech.com/budaschnozzle-20-ptfe-tube-for-1753mm-filament-p-787.html PTFE] liner can be replaced by using an off-the-shelf piece of [http://www.geeetech.com/budaschnozzle-20-ptfe-tube-for-1753mm-filament-p-787.html PTFE] tubing. |

| − | * The PTFE is not stressed nor used to provide support. This reduces a point of failure that is part of other designs. | + | * The [http://www.geeetech.com/budaschnozzle-20-ptfe-tube-for-1753mm-filament-p-787.html PTFE] is not stressed nor used to provide support. This reduces a point of failure that is part of other designs. |

* A resistor is used as a heater. There is no need to wrap nichrome wire or to bake a heater core. | * A resistor is used as a heater. There is no need to wrap nichrome wire or to bake a heater core. | ||

* Heat transmission is improved as there is no thermal junction where a separate heater screws onto the nozzle. | * Heat transmission is improved as there is no thermal junction where a separate heater screws onto the nozzle. | ||

| Line 37: | Line 41: | ||

| Molding form ||| FDM | | Molding form ||| FDM | ||

|- | |- | ||

| − | | Material ||| | + | | Material ||| PEEK |

|- | |- | ||

| Nozzle diameter ||| [http://www.geeetech.com/03mm-nozzle-for-reprap-3d-printer-hotend-p-785.html 0.3], [http://www.geeetech.com/nozzle-035mm-m10aluminum-6063-for-3d-printer-hotend-extruder-p-697.html 0.35], [http://www.geeetech.com/04mm-nozzle-for-reprap-3d-printer-hotend-p-643.html 0.4] , [http://www.geeetech.com/05mm-nozzle-for-reprap-3d-printer-hotend-p-731.html 0.5] optional | | Nozzle diameter ||| [http://www.geeetech.com/03mm-nozzle-for-reprap-3d-printer-hotend-p-785.html 0.3], [http://www.geeetech.com/nozzle-035mm-m10aluminum-6063-for-3d-printer-hotend-extruder-p-697.html 0.35], [http://www.geeetech.com/04mm-nozzle-for-reprap-3d-printer-hotend-p-643.html 0.4] , [http://www.geeetech.com/05mm-nozzle-for-reprap-3d-printer-hotend-p-731.html 0.5] optional | ||

| Line 47: | Line 51: | ||

| Movement speed ||| 50cc | | Movement speed ||| 50cc | ||

|- | |- | ||

| − | | Outline dimensions ||| 18*65*15mm L/H/W | + | | Outline dimensions ||| 18*65*15mm L/H/W |

|- | |- | ||

| Weight ||| 50g | | Weight ||| 50g | ||

| Line 55: | Line 59: | ||

| Heating voltage of extruding head ||| 12V | | Heating voltage of extruding head ||| 12V | ||

|- | |- | ||

| − | | | + | | [http://www.geeetech.com/10pcs-100kohm-ntc-thermistors-for-jietai-hotend-p-836.html Thermistor] ||| 100K 1% high-precision NTC Thermistor |

|- | |- | ||

| [http://www.geeetech.com/12v-30w-cartridge-wire-heater-heating-wire-p-804.html Cartridge heater] ||| 12V 30W | | [http://www.geeetech.com/12v-30w-cartridge-wire-heater-heating-wire-p-804.html Cartridge heater] ||| 12V 30W | ||

|} | |} | ||

| − | |||

== How to buy == | == How to buy == | ||

Click here to buy [http://www.geeetech.com/assembled-jhead-hot-end-030350405mm-nozzle-for-1753mm-p-748.html PEEK J-head short-distance] | Click here to buy [http://www.geeetech.com/assembled-jhead-hot-end-030350405mm-nozzle-for-1753mm-p-748.html PEEK J-head short-distance] | ||

Latest revision as of 00:50, 23 June 2014

Description

This J-Head Hot End is assembled and designed based on other nozzle. It's very simple by reducing the number of custom machined parts to a bare minimum. The J-Head Hot End can easily and well interface with the most popular RepRap extruders.

parts to a bare minimum. The J-Head Hot End can easily and well interface with the most popular RepRap extruders. The filament path is same with teh one of an already proven design, it can be used to print reliably with both ABS and PLA. If using PLA, it requires a small fan to provide air-flow through the cooling vents milled in the sides of the nozzle holder. Besides, the Hot End has another two advantages. Heat transmission is more efficiency as there is no thermal junction where a separate heater screws onto the nozzle. And a resistor is used as a heater. There is no need to wrap nichrome wire or to bake a heater core.

This product is of J-head Hot End design. It adopts high-quality PEEK heat-insulated pipe and duralumin alloy nozzle, with Teflon heat-insulated pipe built in, which prevents blockage effectively and is easy to clean. Besides, its surface is covered with anodic oxide coating, which can resist oxidation corrosion and increase nozzle hardness, thus ensuring finer and more stable printing.

This nozzle is a combination of ideas from other nozzle designs combined with a goal to reduce the number of custom machined parts to a bare minimum. By reducing the number of machined parts, it is hoped that the cost of this hot-end can be kept down while improving the reliability.

The idea of using the PTFE tubing as a liner, from the Cold End to the tip, was borrowed from the Makerbot Mk V extruder design.

Advantages

- Internally, the filament path is identical to that of an already proven design.

- The design is simple as the number of custom machined parts is kept to a minimum.

- If necessary, the PTFE liner can be replaced by using an off-the-shelf piece of PTFE tubing.

- The PTFE is not stressed nor used to provide support. This reduces a point of failure that is part of other designs.

- A resistor is used as a heater. There is no need to wrap nichrome wire or to bake a heater core.

- Heat transmission is improved as there is no thermal junction where a separate heater screws onto the nozzle.

Product Introduction

| Suitable raw material | PLA and ABS |

| Printing material | 1.75mm or 3mm ABS or PLA |

| Printing resolution | 0.1mm |

| Molding form | FDM |

| Material | PEEK |

| Nozzle diameter | 0.3, 0.35, 0.4 , 0.5 optional |

| Printing thickness | 0.1mm-0.3mm |

| Nozzle temperature | 180℃-240℃ |

| Movement speed | 50cc |

| Outline dimensions | 18*65*15mm L/H/W |

| Weight | 50g |

| Input voltage | default to 12V |

| Heating voltage of extruding head | 12V |

| Thermistor | 100K 1% high-precision NTC Thermistor |

| Cartridge heater | 12V 30W |

How to buy

Click here to buy PEEK J-head short-distance