I have a 2017 Geeetech Pro B.

I have had a load of problems, but one i have not solved yet is my Extrusion motor (the mk8) is clicking and seems to be missing steps, also i have a VERY hard time removing the filament every time.

Clicing and missing steps > I am aware i should try to tweak the voltage (please provide the best guide), but before i do that, is there any mechanical tweak or check i should do ? I want to move to a Bowden setup, which extruder mechanism would you recommend ? (new or printed)

Filament Hard to remove > This filament is 190/205 and i tried heating at 110, no way, then 195.. same MK8 could not reverse extrude and it would be SUPER hard to pull out by force.

Firwmare optimising > Any special settings on this motor to optimise STEPS ? I don't care about speed, only quality

Mk8 Motor Extrudor (missing steps, clicking noise)

-

rotormansa

- Posts: 66

- Joined: Tue Mar 07, 2017 12:38 am

Re: Mk8 Motor Extrudor (missing steps, clicking noise)

Same issue here. In my opinion the stepper motor on the extruder is too small and doesn't provide enough torque. For now I've cranked my driver boards up a bit and now have about 1.5A driving the extruder motor. I don't hear the clicks too often now but when I do it's puzzling since there is no obstruction of the filament feed. I have found increasing the temperature a bit makes the issues go away but not always.

I think the problem is s combination of too small a motor and a poorly design feed mechanism. Seems like a number of folks have the same issue but I've not seen any solutions to solve the problem.

I think the problem is s combination of too small a motor and a poorly design feed mechanism. Seems like a number of folks have the same issue but I've not seen any solutions to solve the problem.

Re: Mk8 Motor Extrudor (missing steps, clicking noise)

Hi,

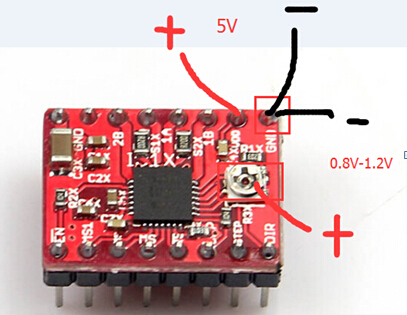

1、Clicing and missing steps >you can set the voltage of driver board in 0.8~1.2V.

.Besides,you check this post to make troubleshooting:viewtopic.php?f=19&t=17097.I will recommend the new extruder mechanism.

2、Filament Hard to remove > To remove the filament,you can reverse the motor of extruder by maunal control in the Repetier Host.Just like the attachment shows.

3、To increase the print quality,you can check these following link:viewtopic.php?f=26&t=17183.And the video maybe helpful too:https://www.youtube.com/watch?v=fb7lit5 ... e=youtu.be.

1、Clicing and missing steps >you can set the voltage of driver board in 0.8~1.2V.

.Besides,you check this post to make troubleshooting:viewtopic.php?f=19&t=17097.I will recommend the new extruder mechanism.

2、Filament Hard to remove > To remove the filament,you can reverse the motor of extruder by maunal control in the Repetier Host.Just like the attachment shows.

3、To increase the print quality,you can check these following link:viewtopic.php?f=26&t=17183.And the video maybe helpful too:https://www.youtube.com/watch?v=fb7lit5 ... e=youtu.be.

- Attachments

-

- reverse the motor of extruder .png (142.33 KiB) Viewed 15533 times

-Keep your mind and try to test it.

-Everything will be fun!-Support all Getech printer.

-You can ask me the questions and I will kindly reply.

-Respect others is the best way you can get help!

-Everything will be fun!-Support all Getech printer.

-You can ask me the questions and I will kindly reply.

-Respect others is the best way you can get help!

-

rotormansa

- Posts: 66

- Joined: Tue Mar 07, 2017 12:38 am

Re: Mk8 Motor Extrudor (missing steps, clicking noise)

@william... all relevant. One of my bigger surprised when experimenting on the "click of death" is that applying more pressure against the filament drive gear is only a partial solution. If the temperature is set appropriately applying more pressure will not stop the COD from happening. The COD is caused by the stepper motor not having enough torque to move the gear to the next step. This is caused by three issues;

1. The filament can't pass through the extruder tube

2. The filament spool isn't free to rotate freely.

3. Insufficient drive current to the stepper motor.

#2 is is an easy one to fix.

#1 is caused by insufficient melting temperature. PLA melt temperatures are not all within the range that are generally posted on the Geeetech site. An example, Dockwell PLA filament doesn't melt well until about 218C and in my experiments best results were achieved at 220C to 230C depending on color. I've learned not to believe published specs on melt temperature but rather run a few calibration cube tests to verify the appropriate settings. Of course filament not passing through the extruder tube could be caused by a blockage, something that PLA is very good at causing.

#3 can be caused by the driver board drive current to the windings of the motor set too low. I currently have mine set to 1.1V and it provides good results with very little heating of the stepper motor. Low drive current could also be attributed to a bad cable. The extruder cable is one of the two weak points of the design since both the extruder and X axis motors move a lot and the cable moves with the motor. This constant movement causes the cable wires to become brittle and fracture leaving the strands in the cable to carry the current which because of fewer strands less current can be seen at the motor. In some cases the cable is completely fractured and in this case the motor only can move 1/2 of the full step the driver is commanding.

Those are my thoughts.

1. The filament can't pass through the extruder tube

2. The filament spool isn't free to rotate freely.

3. Insufficient drive current to the stepper motor.

#2 is is an easy one to fix.

#1 is caused by insufficient melting temperature. PLA melt temperatures are not all within the range that are generally posted on the Geeetech site. An example, Dockwell PLA filament doesn't melt well until about 218C and in my experiments best results were achieved at 220C to 230C depending on color. I've learned not to believe published specs on melt temperature but rather run a few calibration cube tests to verify the appropriate settings. Of course filament not passing through the extruder tube could be caused by a blockage, something that PLA is very good at causing.

#3 can be caused by the driver board drive current to the windings of the motor set too low. I currently have mine set to 1.1V and it provides good results with very little heating of the stepper motor. Low drive current could also be attributed to a bad cable. The extruder cable is one of the two weak points of the design since both the extruder and X axis motors move a lot and the cable moves with the motor. This constant movement causes the cable wires to become brittle and fracture leaving the strands in the cable to carry the current which because of fewer strands less current can be seen at the motor. In some cases the cable is completely fractured and in this case the motor only can move 1/2 of the full step the driver is commanding.

Those are my thoughts.

Re: Mk8 Motor Extrudor (missing steps, clicking noise)

Try this for a mechanical fix...

The clicking noise is the extruder motor stalling. After stripping the extruder mechanism down and checking for broken parts within the pressure roller assembly I exchanged the spring, which was VERY strong, for a weaker one. The strong spring was making the pressure roller and filament act like a brake which stalled the stepper.

I've since ordered the aluminium extruder mechanism with the fully adjustable spring to fix this. In the mean time, by fitting a weaker spring (which I stretched from 2.5cmto 3cm to increase the pressure slightly) I am no longer getting stalls/clicks and the motor is feeding. I've marked a small dot on the recessed right hand end of the shaft with a sharpie pen to indicate it's rotating correctly. Not perfect, but better.

Replacement parts due soon!!

EDIT:

An update on the above... If the spring is too weak you'll obviously not get the filament fed, you'll get the toothed feed gear spinning against the filament and grinding it away.

On the electrical side, for the A4988 driver (I think mine are the Stepstick type) increasing the Vref will increase the current through the phase windings but the higher the current, the more heat stress to both the motor and the driver. While not moving, the windings will still be pulling the current you set - just to lock the phases!

Assuming the standard 0.2 Ohm sense resistor;

Vref 0.8V gives 1 Amp

Vref 1.2V gives 1.5 Amp

Vref 1.6 gives 2 Amp

2 Amps is a bit too high in my estimation. You really need to achieve a balance of spring force and drive current to achieve a good flow. The extruder temperature, type/make of the filament and feed rate are other variables which will affect this. Run tests while only adjusting ONE variable at a time till you (hopefully!) get the results you want.

If one of the two stepper phase windings is open circuit, its feed cabling is broken or its driver is faulty, the motor will just twitch. (You'd have to remove it from the extruder mechanism to see this though) You can use the X or Y steppers/drivers to diagnose

My two cents!

Play Bonny!

Soadyheid

The clicking noise is the extruder motor stalling. After stripping the extruder mechanism down and checking for broken parts within the pressure roller assembly I exchanged the spring, which was VERY strong, for a weaker one. The strong spring was making the pressure roller and filament act like a brake which stalled the stepper.

I've since ordered the aluminium extruder mechanism with the fully adjustable spring to fix this. In the mean time, by fitting a weaker spring (which I stretched from 2.5cmto 3cm to increase the pressure slightly) I am no longer getting stalls/clicks and the motor is feeding. I've marked a small dot on the recessed right hand end of the shaft with a sharpie pen to indicate it's rotating correctly. Not perfect, but better.

Replacement parts due soon!!

EDIT:

An update on the above... If the spring is too weak you'll obviously not get the filament fed, you'll get the toothed feed gear spinning against the filament and grinding it away.

On the electrical side, for the A4988 driver (I think mine are the Stepstick type) increasing the Vref will increase the current through the phase windings but the higher the current, the more heat stress to both the motor and the driver. While not moving, the windings will still be pulling the current you set - just to lock the phases!

Assuming the standard 0.2 Ohm sense resistor;

Vref 0.8V gives 1 Amp

Vref 1.2V gives 1.5 Amp

Vref 1.6 gives 2 Amp

2 Amps is a bit too high in my estimation. You really need to achieve a balance of spring force and drive current to achieve a good flow. The extruder temperature, type/make of the filament and feed rate are other variables which will affect this. Run tests while only adjusting ONE variable at a time till you (hopefully!) get the results you want.

If one of the two stepper phase windings is open circuit, its feed cabling is broken or its driver is faulty, the motor will just twitch. (You'd have to remove it from the extruder mechanism to see this though) You can use the X or Y steppers/drivers to diagnose

My two cents!

Play Bonny!

Soadyheid