Z Wobble Fix For Geeetech Aluminum Prusa I3

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

Forgot the pic...

//UndCon

//UndCon

- Attachments

-

- print.png (755.45 KiB) Viewed 33930 times

-

solder_guy

- Posts: 3

- Joined: Wed Oct 05, 2016 1:08 pm

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

Thank you!!

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

Hi New to this forum

I have just bought a 2016 Geeetech Acrylic Prusa i3b pro kit and put it together two days ago. Its a great kit for the price and I'm happy with it but it has a poor z axis design.

I have the metal z axis bracket and on startup the z-axis stuck at the bottom, the screw threads squeaked up and down and the steppers jumped. I greased the screw threads that they still squeaked and I was losing level calibration.

Looking at the forums this seems to be a common issue. I determined the problem was excessive run out where the lead screws go into the flexible coupling.

When the flexible couplings are tightened the lead screws are thrown off center and rotate in an orbit rather than turn through their centers. The problem is magnified at the bottom and if the screw threads are not perfectly straight.

As the bed approaches the Z axis stepper coupling the run out causes major frictional thrusts between the screw and the 8mm guide rods - The increased friction jams the printer Z drives and they lose steps

I spent a day trying to get the lead screws to run through their centers by careful alignment and packing the flexible couplings. I got the problem to almost acceptable - the bed traveled up and down without too much squeaking or sticking

but I was still not happy with it.

To correct the problem - I removed the bronze screw assembly from beneath the metal carriage and placed it on top of the carriage clear of the alignment hole then supported the carriage with Long 20mm screws going up through the carriage hole and into the bronze screw assembly. The bronze screw assembly is now above a suspended carriage. I filed a small flat on the flange of the bronze screw assembly to giving them clearance on the metal carriage.

The bronze screw now has a small amount of sideways movement to allow for some screw wobble and is further away from the stepper motor coupling where the run-out wobble is greatest.

I now have an extremely smooth z-axis up and down. I did a (about 10 mm high) test print before and after the mod - the test print after was smoother and significantly taller then the print I had done before the mod.

I can only conclude that my z drive screw thread was binding throughout the first print. My carriage appears to be holding level calibration.

This mod requires no drilling or modifications to the frame or bed and I used the existing equipment from the kit in a reconfigured way.

regards moorebrm

I have just bought a 2016 Geeetech Acrylic Prusa i3b pro kit and put it together two days ago. Its a great kit for the price and I'm happy with it but it has a poor z axis design.

I have the metal z axis bracket and on startup the z-axis stuck at the bottom, the screw threads squeaked up and down and the steppers jumped. I greased the screw threads that they still squeaked and I was losing level calibration.

Looking at the forums this seems to be a common issue. I determined the problem was excessive run out where the lead screws go into the flexible coupling.

When the flexible couplings are tightened the lead screws are thrown off center and rotate in an orbit rather than turn through their centers. The problem is magnified at the bottom and if the screw threads are not perfectly straight.

As the bed approaches the Z axis stepper coupling the run out causes major frictional thrusts between the screw and the 8mm guide rods - The increased friction jams the printer Z drives and they lose steps

I spent a day trying to get the lead screws to run through their centers by careful alignment and packing the flexible couplings. I got the problem to almost acceptable - the bed traveled up and down without too much squeaking or sticking

but I was still not happy with it.

To correct the problem - I removed the bronze screw assembly from beneath the metal carriage and placed it on top of the carriage clear of the alignment hole then supported the carriage with Long 20mm screws going up through the carriage hole and into the bronze screw assembly. The bronze screw assembly is now above a suspended carriage. I filed a small flat on the flange of the bronze screw assembly to giving them clearance on the metal carriage.

The bronze screw now has a small amount of sideways movement to allow for some screw wobble and is further away from the stepper motor coupling where the run-out wobble is greatest.

I now have an extremely smooth z-axis up and down. I did a (about 10 mm high) test print before and after the mod - the test print after was smoother and significantly taller then the print I had done before the mod.

I can only conclude that my z drive screw thread was binding throughout the first print. My carriage appears to be holding level calibration.

This mod requires no drilling or modifications to the frame or bed and I used the existing equipment from the kit in a reconfigured way.

regards moorebrm

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

Welcome to the forum moorebrm!

I'm glad to hear you sorted the issue with Z. It seems you found another solution and that's cool.

Personally I use the printed parts above and a 2nd version that has a regular HEX-nut

I have no issues on Z with above mod and it took like 20 minutes to print.

BTW - I hope you got the parts I printed for you solder_guy ?

I'm glad to hear you sorted the issue with Z. It seems you found another solution and that's cool.

Personally I use the printed parts above and a 2nd version that has a regular HEX-nut

I have no issues on Z with above mod and it took like 20 minutes to print.

BTW - I hope you got the parts I printed for you solder_guy ?

-

mannymiller

- Posts: 14

- Joined: Mon Feb 27, 2017 4:27 am

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

Hi, i have just printed a set of these for my pro b version. My wobble isnt so bad but thought i would upgrade them anyway. where it fits either side of the smooth rod should it be a snug fit ? as i seem to have about a 1m gap either side. i know my calibration is ok.. just thought i would check before installing them.

thanks in advance.

thanks in advance.

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

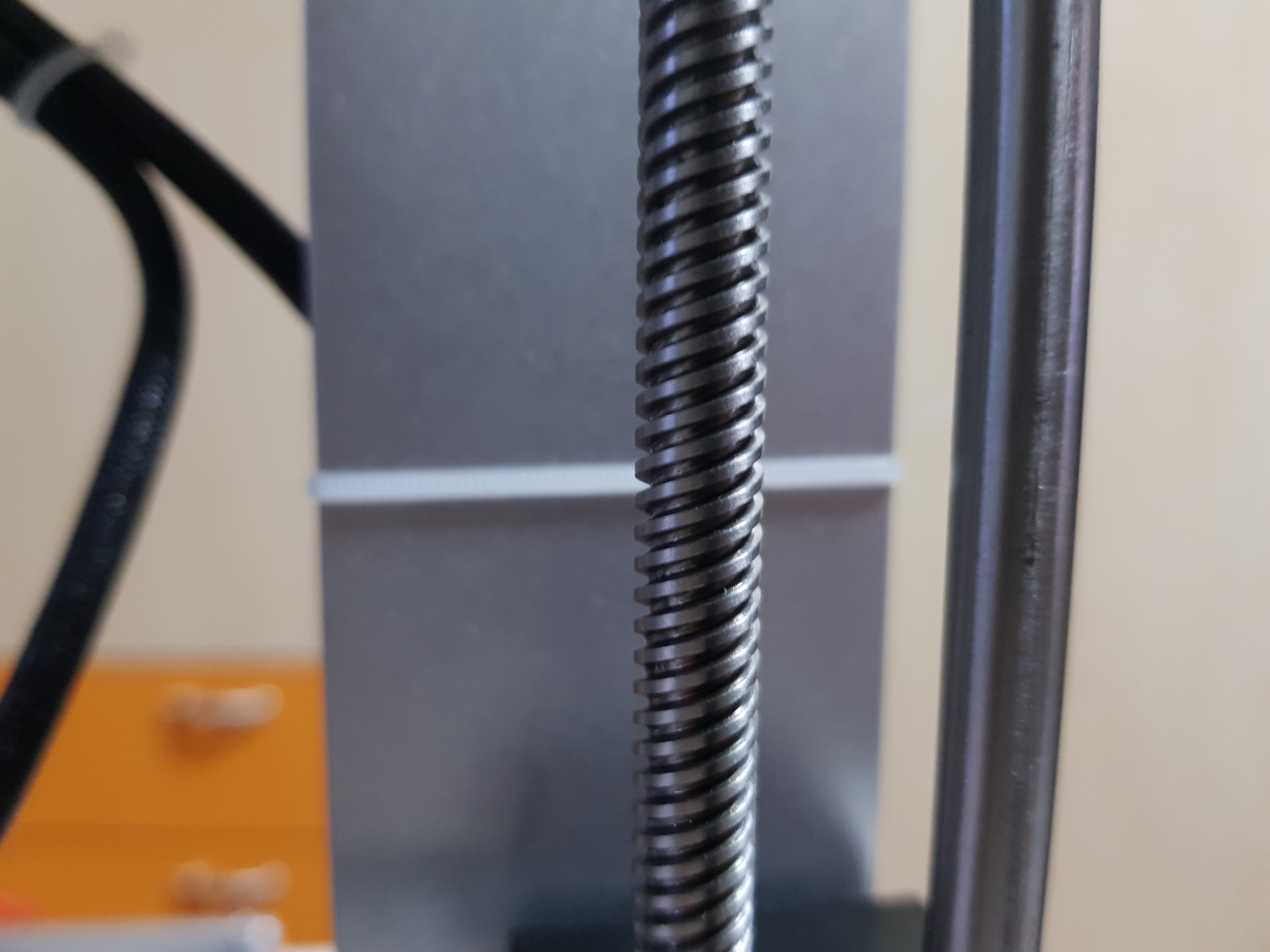

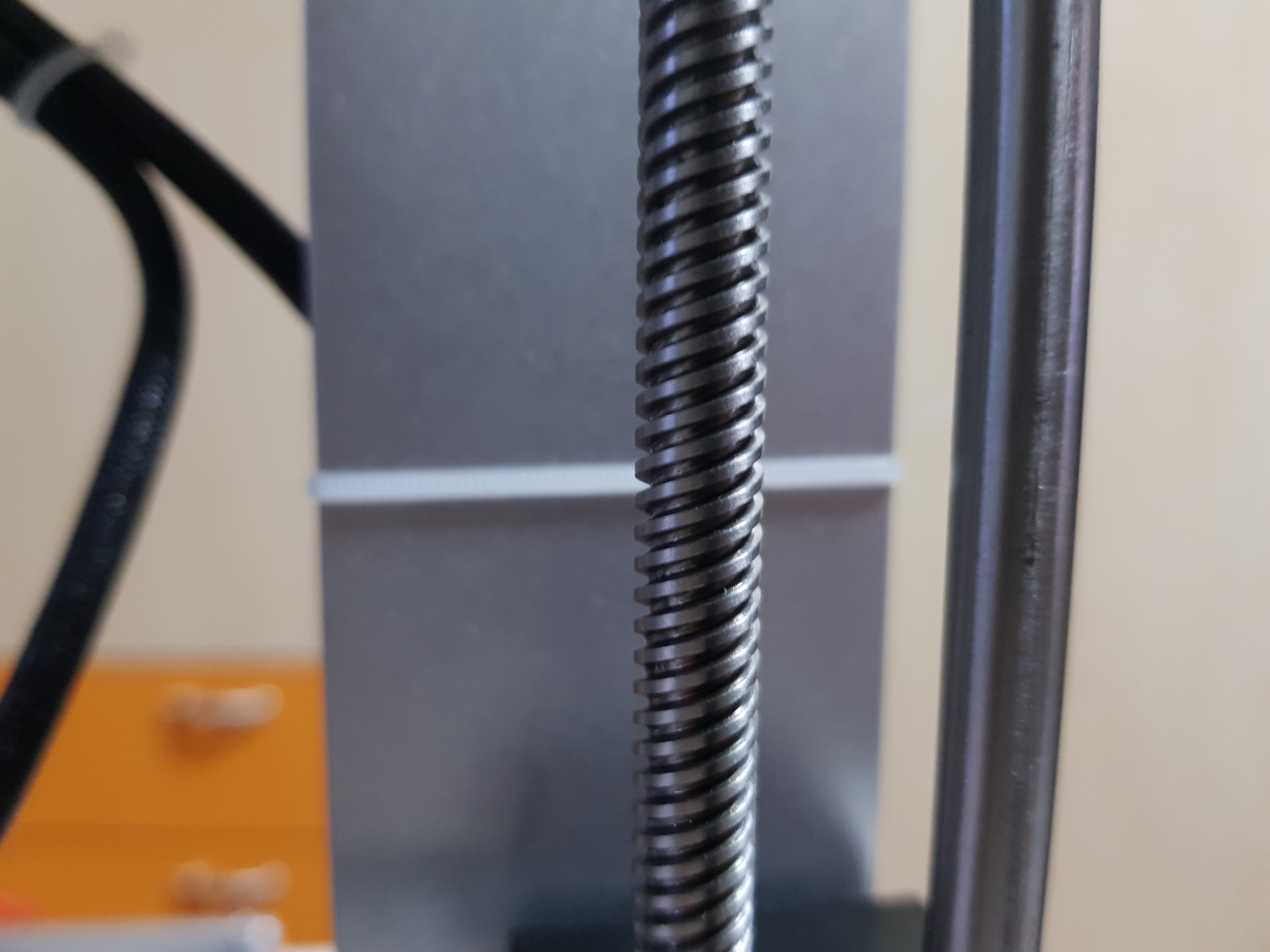

Hi, I want to make this change to my Geeetech i3 Aluminium, I printed the 2 pieces, but I can not find anywhere 2 nuts that fit the z-axis thread, the threaded bar of my printer is different from the one in Photos in the first post, I put a picture:

Does anyone know what kind of nut I should look for? Maybe you put a link to buy them online ... Thank you!

Does anyone know what kind of nut I should look for? Maybe you put a link to buy them online ... Thank you!

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

You can find the seller for the nuts size or directly print it.

-Keep your mind and try to test it.

-Everything will be fun!-Support all Getech printer.

-You can ask me the questions and I will kindly reply.

-Respect others is the best way you can get help!

-Everything will be fun!-Support all Getech printer.

-You can ask me the questions and I will kindly reply.

-Respect others is the best way you can get help!

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

Thanks for the reply, I sent an email yesterday to the seller, I'm waiting for a reply, you know what nut I should print? Is the model on Thingiverse? Then for more accuracy and durability I thought better than 2 metal nuts.

I was hoping to receive a more accurate answer on the official Geeetech forum...

I was hoping to receive a more accurate answer on the official Geeetech forum...

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

I find a model but I am not sure whether it suits your need,here I share you a link:

www.thingiverse.com/thing:1431036

www.thingiverse.com/thing:1431036

-Keep your mind and try to test it.

-Everything will be fun!-Support all Getech printer.

-You can ask me the questions and I will kindly reply.

-Respect others is the best way you can get help!

-Everything will be fun!-Support all Getech printer.

-You can ask me the questions and I will kindly reply.

-Respect others is the best way you can get help!

Re: Z Wobble Fix For Geeetech Aluminum Prusa I3

Thanks, I did not see this remix!

With this I do not need hexagonal nuts, I use those with the 3d printer, I had found others but this seems better because the top cylinder stays out of the hole.

Try it now, thanks a lot !!!

With this I do not need hexagonal nuts, I use those with the 3d printer, I had found others but this seems better because the top cylinder stays out of the hole.

Try it now, thanks a lot !!!