Under extrusion

Under extrusion

I can not get this dialed in. I am getting good prints in the beginning layers and then it starts to under extrude "I assume" about 6-10mm into the print. I have just replaced a new hot end with new nozzle and still get the same results. I am printing PLA at 205, have the esteps set to 430 "which helped some", the drive gear for the filament is not showing grinds on the teeth, I have tried an estep calibration and if I set it to extrude 100mm of filament I get 40mm extruded. I know when I got this that the esteps were around the 320's and it printed the dog great and several other prints, I didn't change any settings and the printer sat about 6-8 weeks and I cant print the dog without the infill crushing very easily. Has anyone else had this problem or know of a fix. I see a lot of people with under extrusion problems and I checked out a lot of solutions but no help. Here are a few pics of a test calibration that I printed out.

- Attachments

-

- 3.jpg (166.74 KiB) Viewed 7971 times

-

- 2.jpg (181.13 KiB) Viewed 7971 times

-

- 1.jpg (196.01 KiB) Viewed 7971 times

Re: Under extrusion

When I did the estep calibration, I did change esteps to get a full 100mm to extrude but they were at 1200 And it was Really over extruding then. I’ve tried playing with the esteps but the mid 400s seem to be the best but I cannot get a consistent print

Re: Under extrusion

Thank you, I will look into that tomorrow. I forgot to add that both extruders are giving me the same results. I’m assuming the same jumper would have to be not making contact on both extruders.

Re: Under extrusion

I took the jumpers off and they all were getting contact and I put them all back on and I still get the same results.

- Attachments

-

- 2.jpg (181.13 KiB) Viewed 7947 times

-

- 1.jpg (196.01 KiB) Viewed 7947 times

Re: Under extrusion

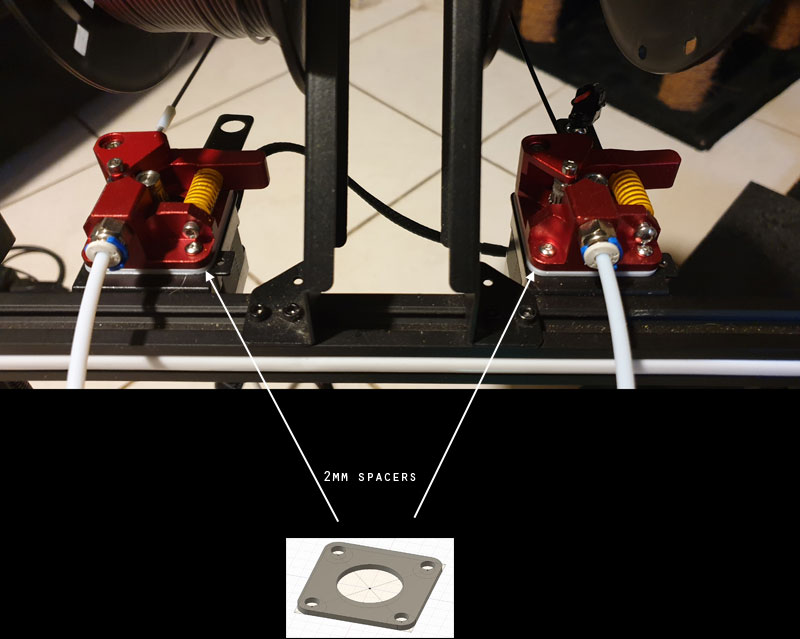

Maybe one piece is broken inside your extruders, it happend to me, it can make filament to slip while extruding.

As stock extruders was really poor and broken on my A20m, I ended using full metal and double geared one (same extruders than CR10S pro require 140 steps/mm). Now I am sure that both extruders works perfectly.

As stock extruders was really poor and broken on my A20m, I ended using full metal and double geared one (same extruders than CR10S pro require 140 steps/mm). Now I am sure that both extruders works perfectly.

Re: Under extrusion

They do look like a lot better quality extruder but I really hate to put more money into something that is still under warranty and I also didn’t think that this could be the issue since I started having problems with both extruders at the same time, I figured if it was the extruder that I would at least get good prints off of one of them

Re: Under extrusion

Other ideas :

maybe you are printing too fast for the temperature you used, when printing faster you need to increase nozzle temperature accordingly so that the plastic have enough time to melt. So maybe try to increase temperature or slowing the print speed.

Edit : I never had reliable extrusion with the stock extruders. Everything has started going right when I changed them for full metal

maybe you are printing too fast for the temperature you used, when printing faster you need to increase nozzle temperature accordingly so that the plastic have enough time to melt. So maybe try to increase temperature or slowing the print speed.

Edit : I never had reliable extrusion with the stock extruders. Everything has started going right when I changed them for full metal