Advice needed - Is i3 X suitable for my application?

Posted: Wed Mar 01, 2017 7:58 am

I make workshop tools and have seen an application to use a 3d printer since they first hit the market a few years ago.

However until more recently with the new filaments such as XT-CF20 they just were not capable of making parts of the desired strength.

But can i consider them as a viable solution now?

So i am looking at an affordable kit and the i3 X seems the best option to trial as there is a large community with ready to print upgrades and mods... but wish to know if it can even do the job?

I have done a little homework and am already aware that it needs some upgrades after getting up and running:

Frame, XYZ, linear bearings, work piece cooling, bigger psu, giving me chance to learn to use the printer.

Then upgrade to an e3d V6 Bowden with hardened steel nozzle, get that dialled in and good to go with xt-cf20.

Would a 30A (360W) psu be big enough upgrade for this machine or will i need to go higher when i upgrade to the Bowden?

Will i be able to achieve rapid prototyping prints within a tolerance of 0.1mm on all 3 axis?

Can i achieve that tolerance without replacing the main hardware (steppers, motor controllers, electronics threaded bars, rails etc.)?

Building the kit, slic3r, calibration, printable upgrades i can do, but i would need to learn how to use the cad software as ive always been useless with cad!

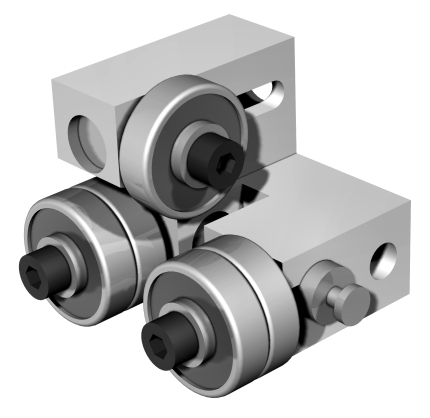

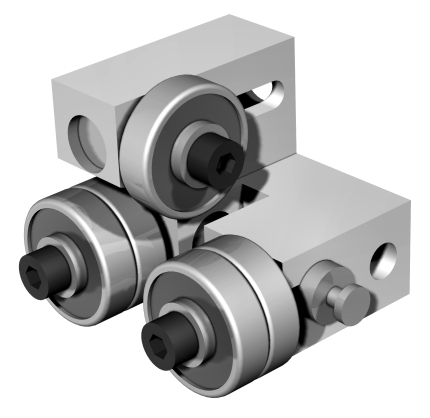

Examples of application:

Jig component parts,

Low friction track runners,

Enclosures,

Precision cast parts for powered machinery

http://jayscustomcreations.com/wp-conte ... jig-19.jpg

For scale the bearings in the first 2 pictures are 6mm ID, the bearings in the last picture are 8mm ID, 10mm ID and 12mm ID

However until more recently with the new filaments such as XT-CF20 they just were not capable of making parts of the desired strength.

But can i consider them as a viable solution now?

So i am looking at an affordable kit and the i3 X seems the best option to trial as there is a large community with ready to print upgrades and mods... but wish to know if it can even do the job?

I have done a little homework and am already aware that it needs some upgrades after getting up and running:

Frame, XYZ, linear bearings, work piece cooling, bigger psu, giving me chance to learn to use the printer.

Then upgrade to an e3d V6 Bowden with hardened steel nozzle, get that dialled in and good to go with xt-cf20.

Would a 30A (360W) psu be big enough upgrade for this machine or will i need to go higher when i upgrade to the Bowden?

Will i be able to achieve rapid prototyping prints within a tolerance of 0.1mm on all 3 axis?

Can i achieve that tolerance without replacing the main hardware (steppers, motor controllers, electronics threaded bars, rails etc.)?

Building the kit, slic3r, calibration, printable upgrades i can do, but i would need to learn how to use the cad software as ive always been useless with cad!

Examples of application:

Jig component parts,

Low friction track runners,

Enclosures,

Precision cast parts for powered machinery

http://jayscustomcreations.com/wp-conte ... jig-19.jpg

For scale the bearings in the first 2 pictures are 6mm ID, the bearings in the last picture are 8mm ID, 10mm ID and 12mm ID